A fully automatic packaging and palletizing device for 2,6-di-tert-butyl-4-methylphenol

A fully automatic packaging and fully automatic packaging machine technology, which is applied in the field of palletizing devices and material packaging, can solve the problems of large error in the packaging accuracy of antioxidant BHT, poor manual sewing effect, and shortage of manual labor, etc., to achieve reduction Effects of pollution, reduction of production and operation costs, and reduction of production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the drawings and specific embodiments.

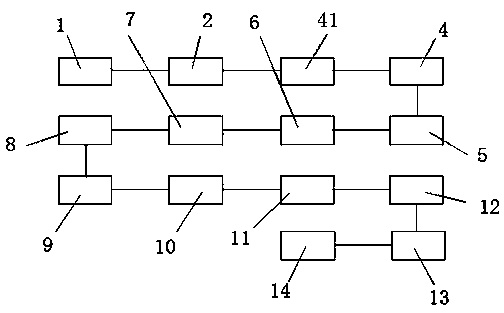

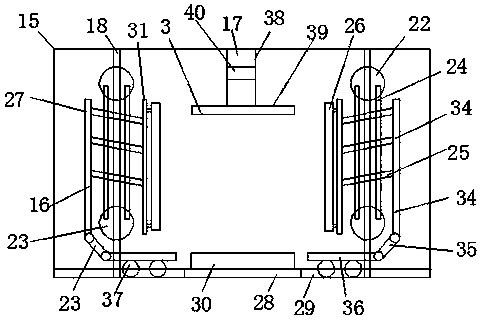

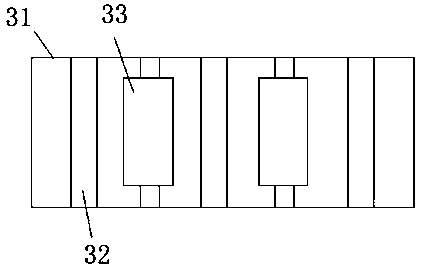

[0024] It can be seen from the accompanying drawings that a fully automatic packaging and palletizing device for 2,6-di-tert-butyl-4-methylphenol includes a first screw feeder 1, a silo 2, and a second screw feeder 42. Fully automatic packaging machine 4, sewing machine 5, right-angle guiding machine 6, conveyor 7, metal detector 8, quality inspection machine 9, rejection and shaping conveyor 10, press shaping machine 11, grab conveyor 12, code The stacking robot 13 and the conveyor 14, the first screw feeder 1 is in sequence with the silo 2, the second screw feeder 41, the fully automatic packaging machine 4, the sewing machine 5, the right angle guiding machine 6, the conveyor 7, the metal The inspection machine 8, the quality inspection machine 9, the rejection shaping conveyor 10, the press shaping machine 11, the grab conveyor 12, the palletizing robot 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com