Making method for flavoring bag

A production method and seasoning bag technology, which is applied in the field of packaging bags, can solve the problem that the seasoning bag cannot be seasoned quickly, and achieve the effect of avoiding random flying of powder and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below by means of specific embodiments:

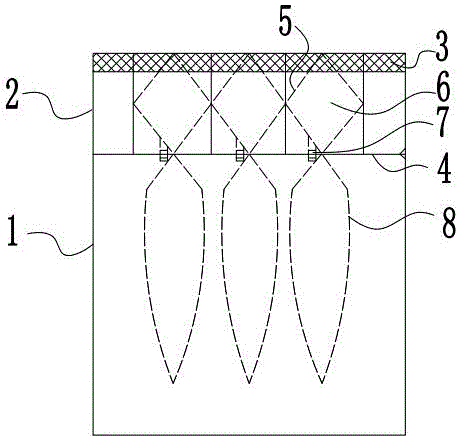

[0034] The reference signs in the drawings of the description include: loading part 1 , tearing strip 2 , shielding strip 3 , tearing line 4 , hinged frame 5 , material bag 6 , connecting plug 7 , and stirring ring 8 .

[0035] Such as figure 1 As shown, the seasoning bag to be produced in this embodiment includes a tear strip 2 with various seasonings on the top and a loading part 1 loaded with basic seasonings connected with the tear strip 2 through the first tear line 4 below. The right end of the tear bar 2 has a tear opening for tearing the first tear line 4. The first tear line 4 is actually a tearable pre-indentation formed by simultaneous pressing on both sides of the packaging bag. The tear strip 2 comprises a plurality of packets 6 connected to each other by a second tear line, and each packet 6 is filled with a different condiment. Each material bag 6 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com