Reinforcement cage seam welder

A technology of steel cage and roll welding machine, which is applied in the direction of roller electrode welding, welding equipment, resistance welding equipment, etc., and can solve the problems of virtual welding, low efficiency, time-consuming and labor-intensive quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

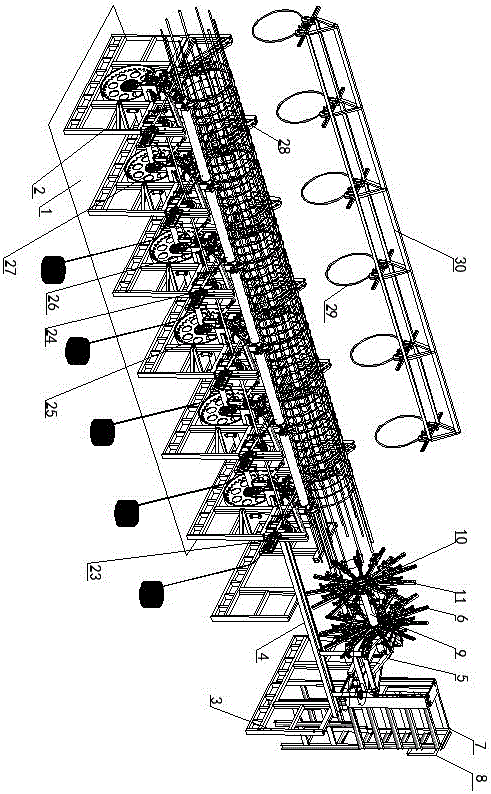

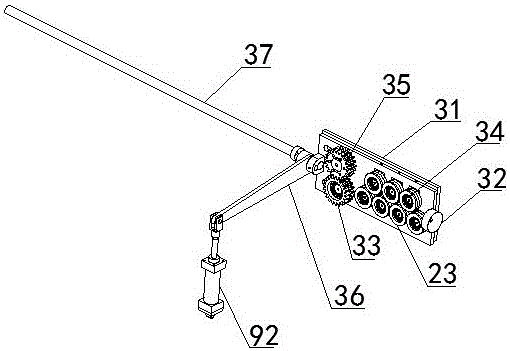

[0030] according to Figures 1 to 12 Shown, the present invention relates to a kind of reinforcement cage roll welding machine, and it comprises base 1, and described base 1 is provided with the bracket 3 with track 4 on the upper part and at least one U-shaped reinforcement cage welding frame body 2, so The track 4 of the support 3 is provided with a mobile frame 5, the central position of the mobile frame 5 is provided with a main stirrup fixing and clamping device 6, and the upper right side of the support 3 is provided with a fixed frame 7 and at its central position A lead screw traction device 8 is provided, and the middle part of one side of the steel cage welding frame body 2 is provided with an outer stirrup conveying device 23, and the upper part of the same side is provided with a main reinforcement rotating device 24, and the steel cage welding frame The middle part of the body 2 is provided with a supporting main reinforcement device 25, and an outer stirrup weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com