A microbial remediation method for oil-contaminated soil

A technology for microbial remediation and oil pollution. It is applied in the restoration of contaminated soil and biological sludge treatment. It can solve the problems of large pollution area, difficult treatment and high toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] a. Collect oil-contaminated soil near the oil well, dry it and crush it to remove volatile hydrocarbons and water;

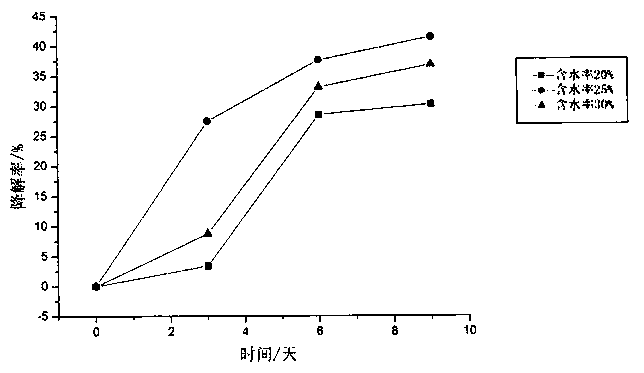

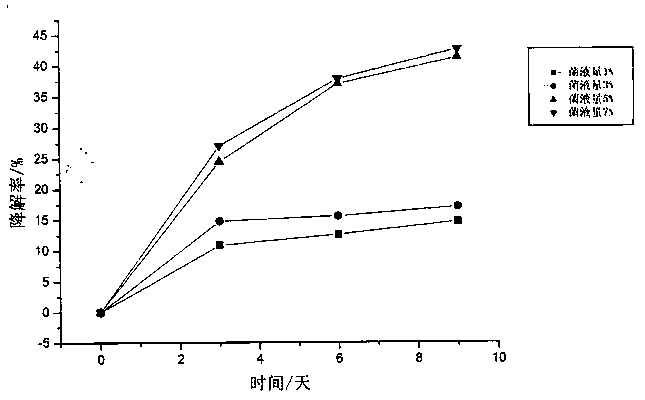

[0020] b. Add the biomass powder with a particle size of 1mm to the soil of step a by volume ratio of 10% as cotton stalk powder and mix evenly, and adjust the water content to 20% and adjust the pH to 7.5;

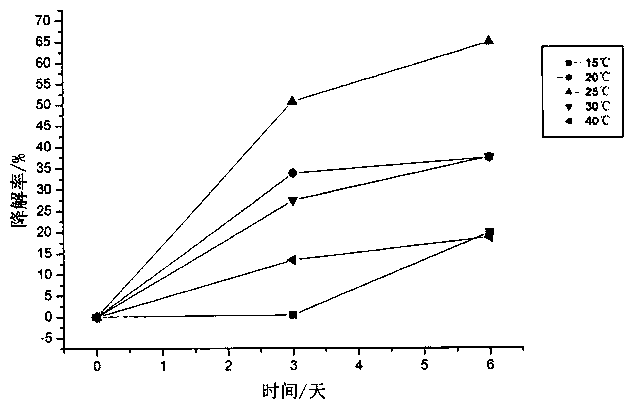

[0021] c. Preparation of crude surfactant: The inorganic salt medium is NH 4 Cl 0.776g, KH 2 PO 4 0.05g, K 2 HPO 4 0.05g, CaCl 2 0.001g, MgSO 4 0.01g, 100mL ultrapure water, pH 7.5, put into a 250mL Erlenmeyer flask, and add 4g n-hexadecane, sterilize at 121℃ for 20min, after cooling, insert Pseudomonasaeruginosa liquid, and use ventilation Seal the membrane and place it in a constant temperature shaker at a temperature of 30°C and incubate at 120r / min for 96 hours to obtain a crude surfactant with a surface tension of 26.68mN / m;

[0022] d. Mix Pseudomonas aeruginosa and Achromobacter sp at a volume ratio of 0.9:1, and connect the mixed bacteria liquid ...

Embodiment 2

[0025] a. Collect oil-contaminated soil near the oil well, dry it and crush it to remove volatile hydrocarbons and water;

[0026] b. Add biomass powder with a particle size of 2mm to the soil of step a by volume at 20% to mix evenly with sawdust, adjust the moisture content to 25%, and adjust the pH to 7.5;

[0027] c. Preparation of crude surfactant: The inorganic salt medium is NH 4 Cl 0.776g, KH 2 PO 4 0.05g, K 2 HPO 4 0.05g, CaCl 2 0.001g, MgSO 4 0.01g, 100mL ultrapure water, pH 7.5, put into a 250mL Erlenmeyer flask, and add 4g n-hexadecane, sterilize at 121℃ for 20min, after cooling, insert Pseudomonasaeruginosa liquid, and use ventilation Seal the membrane and place it in a constant temperature shaker at a temperature of 30°C and incubate at 120r / min for 96 hours to obtain a crude surfactant with a surface tension of 26.68mN / m;

[0028] d. Mix Pseudomonas aeruginosa and Achromobacter sp at a volume ratio of 0.9:1, and connect the mixed bacteria liquid to the soil system ob...

Embodiment 3

[0031] a. Collect oil-contaminated soil near the oil well, dry it and crush it to remove volatile hydrocarbons and water;

[0032] b. Add the biomass powder with a particle size of 3mm to the soil of step a by volume ratio 30% to mix evenly with rice husk, adjust the moisture content to 30%, and adjust the pH to 7.5;

[0033] c. Preparation of crude surfactant: The inorganic salt medium is NH 4 Cl 0.776g, KH 2 PO 4 0.05g, K 2 HPO 4 0.05g, CaCl 2 0.001g, MgSO 4 0.01g, 100mL ultrapure water, pH 7.5, put into a 250mL Erlenmeyer flask, and add 4g n-hexadecane, sterilize at 121℃ for 20min, after cooling, insert Pseudomonasaeruginosa liquid, and use ventilation Seal the membrane and place it in a constant temperature shaker at a temperature of 30°C and incubate at 120r / min for 96 hours to obtain a crude surfactant with a surface tension of 26.68mN / m;

[0034] d. Mix Pseudomonas aeruginosa and Achromobacter sp at a volume ratio of 0.9:1, and connect the mixed bacteria liquid to the soil s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap