Stator for eccentric screw pump, eccentric screw pump and method of manufacturing stator

A technology for eccentric screw pumps and stators, applied to pumps, pump components, rotary piston pumps, etc., can solve problems such as the inability of elastomer materials to achieve precise manufacturing, less wear and tear, and even gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

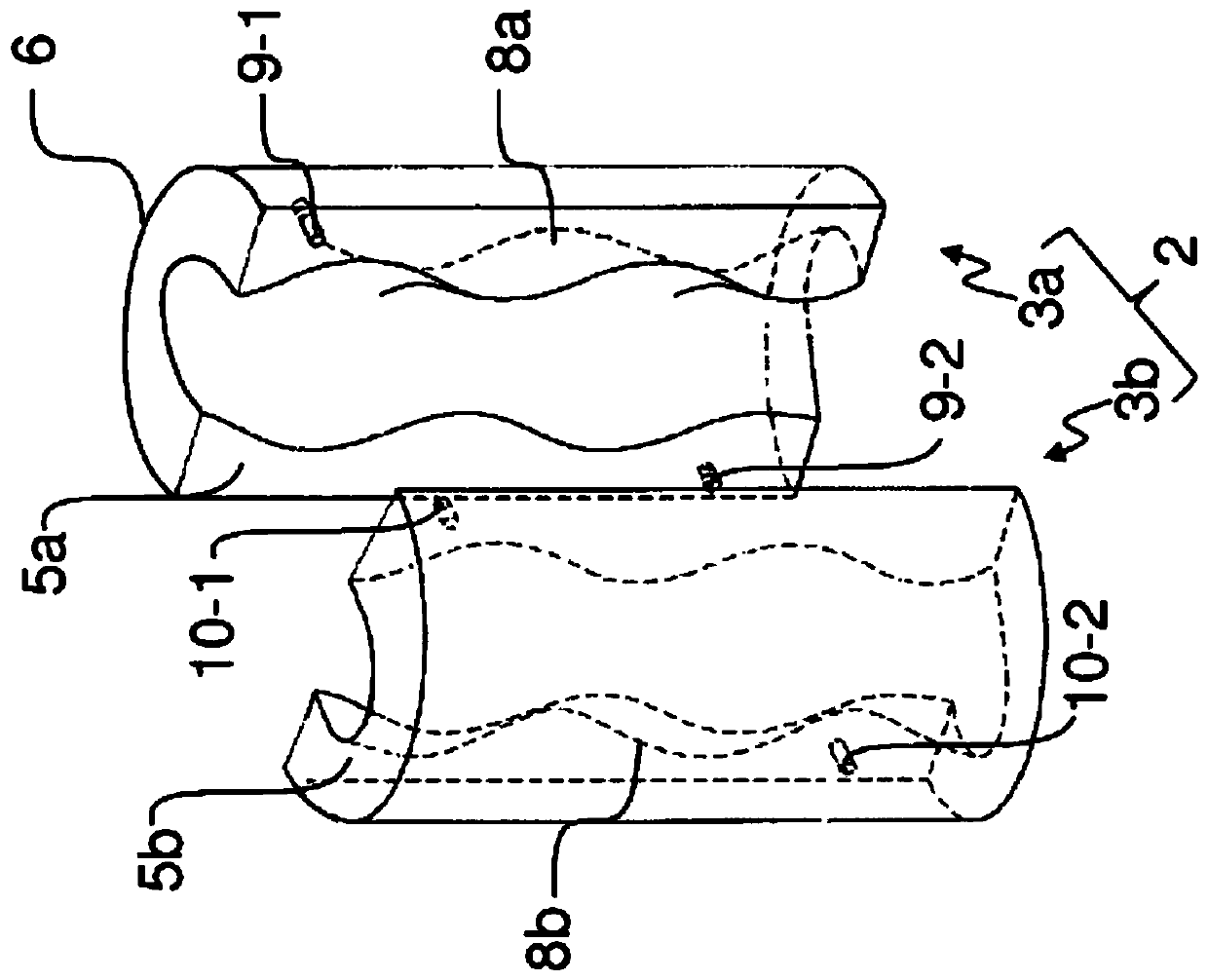

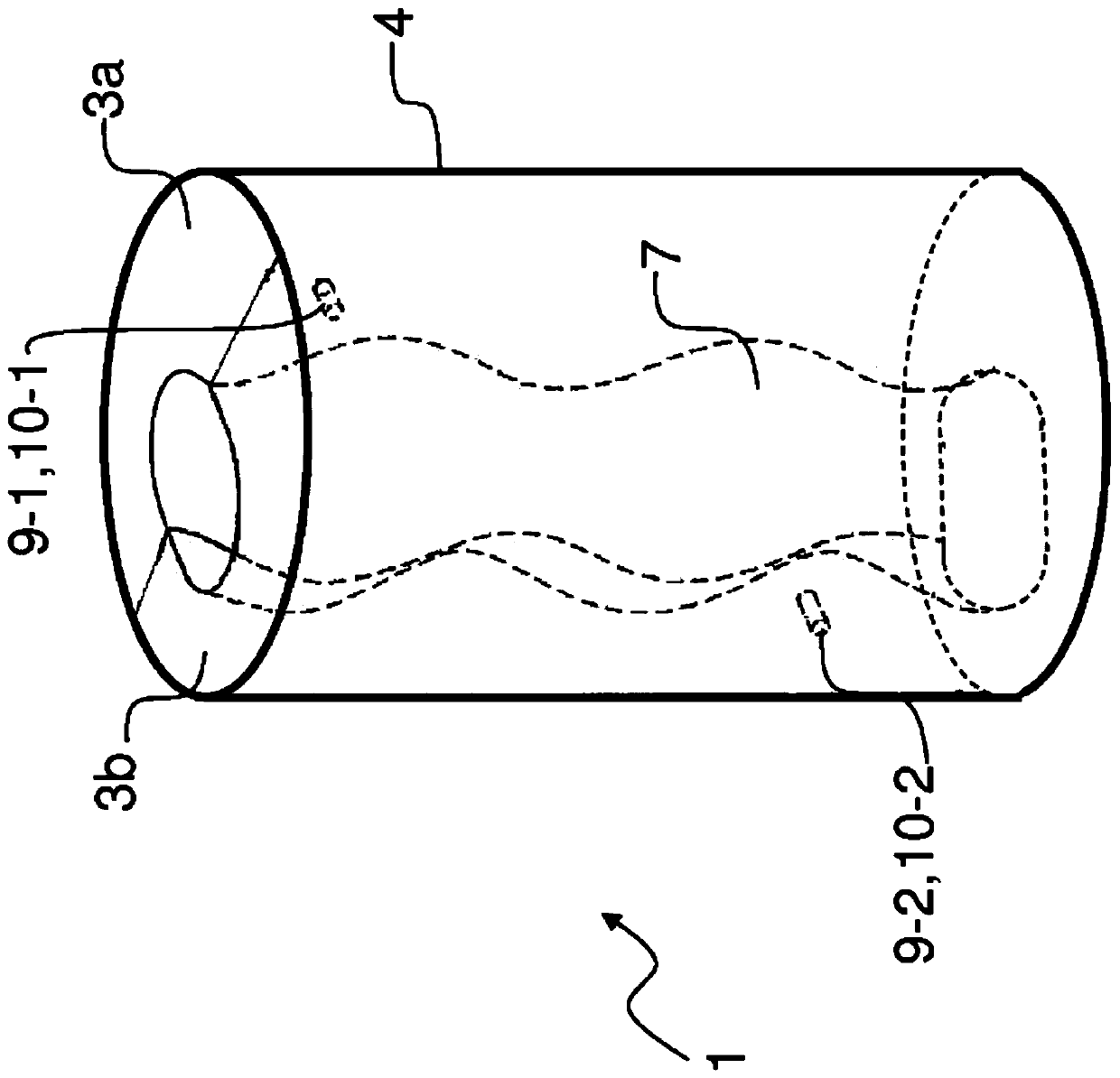

[0030] Figure 1A and Figure 1B A schematic diagram showing the main components of the stator 1 according to the present invention before assembling the stator 1 (compared to figure 2 );and figure 2 A schematic view of a stator 1 manufactured according to the invention is shown. Figure 1ATwo core parts 3 a , 3 b are shown, which together form the stator core 2 . The stator core 2 has a substantially cylindrical outer surface 6 . The core parts 3a, 3b have part configurations (Teilkontur) 8a, 8b respectively, which after the core parts 3a, 3b are assembled together form the inner configuration 7 of the stator 1 (see figure 2 ). The component configurations 8a, 8b are produced with high precision by multi-axis profile milling. It is important for this that the two core parts 3a, 3b have a common base point. One core part 3a comprises two fixing pins 9-1, 9-2 on its contact face 5a with the second core part 3b; and the second core part 3b is in contact with the first cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com