Automatic water quality sampler and operating method thereof

A technology of automatic sampling and working method, applied in the direction of sampling device, etc., can solve the problems of easy loss of positioning method, inaccurate entry of water samples, positioning deviation, etc., and achieve the effects of simple structure, large torque and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

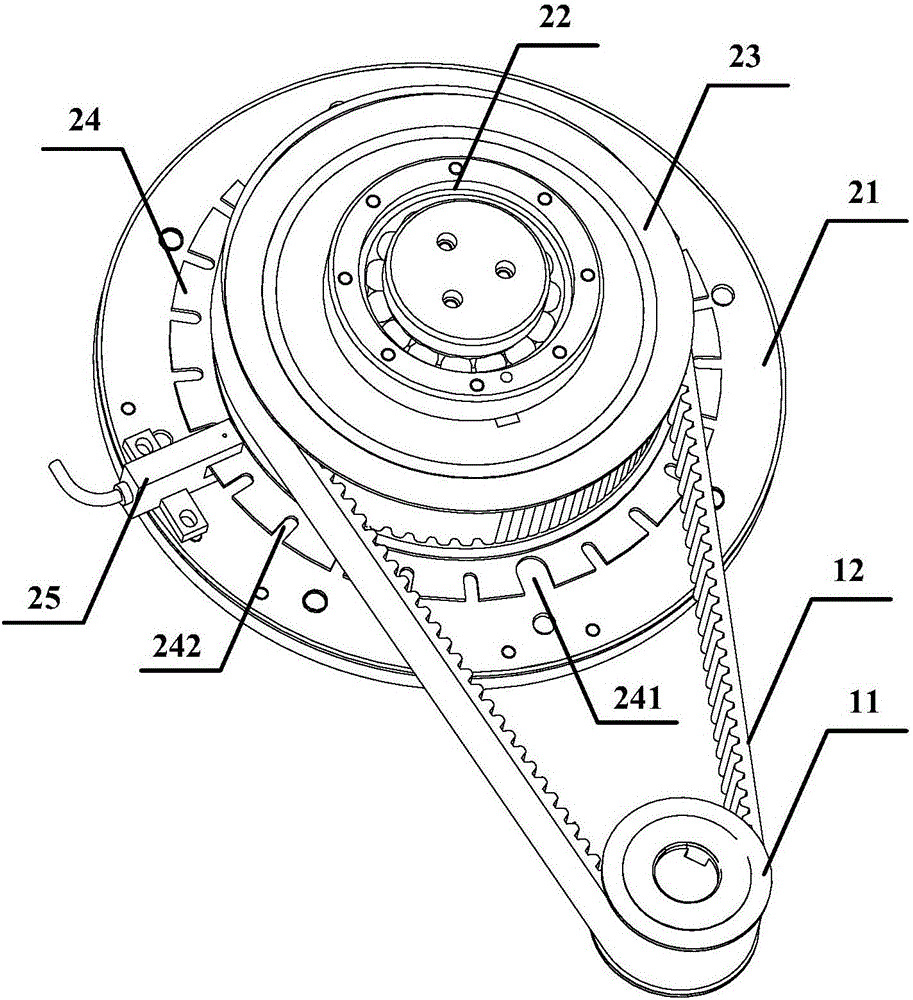

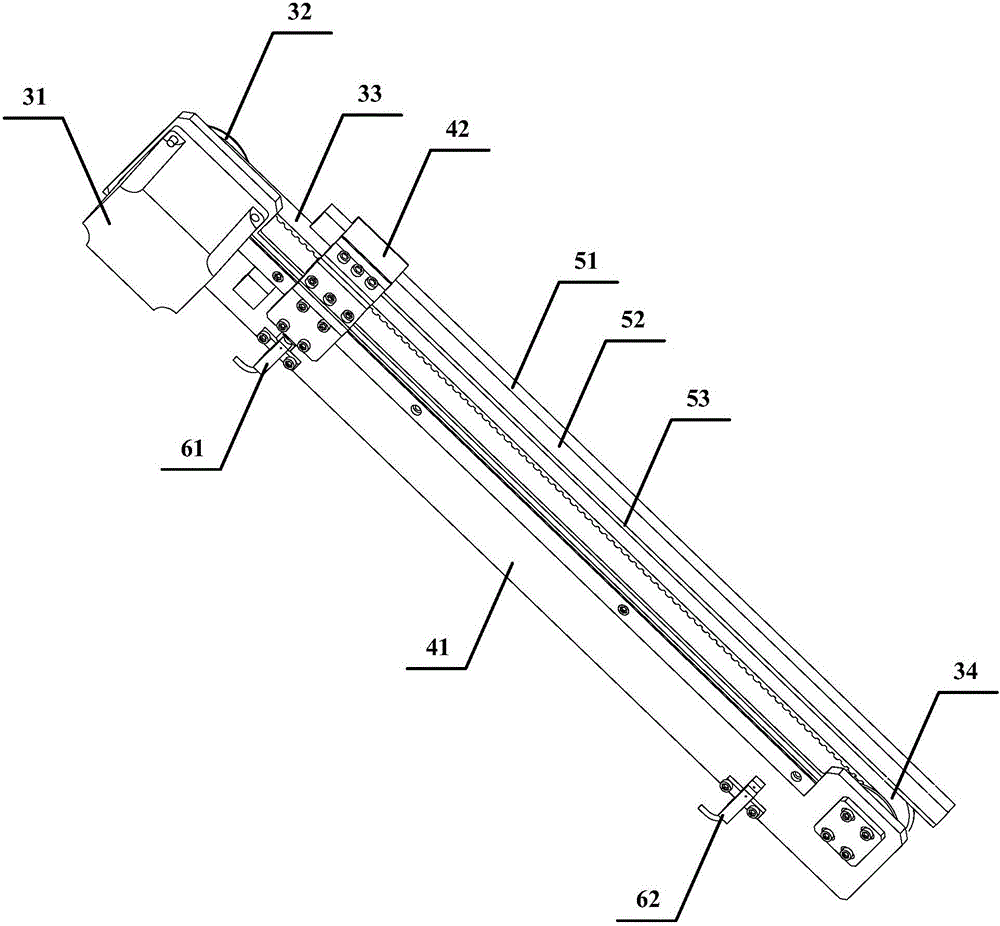

[0051] figure 1 A schematic structural diagram of the rotary positioning device of the water quality automatic sampler of this embodiment is given schematically, figure 2 Schematically provides a schematic structural diagram of the axial positioning device of the water quality automatic sampler of the present embodiment, as Figure 1-2 Shown, described water quality sampler comprises:

[0052] Rotary positioning device, described rotary positioning device is used for at least two retaining sample bottles of retaining sample unit are carried out rotational positioning; Described rotating positioning device comprises power mechanism and positioning mechanism, and described power mechanism comprises: first motor (in the figure not shown), the first synchronous pulley 11 and the first synchronous belt 12; the positioning mechanism further includes:

[0053] fixed block 21;

[0054] A rotary bearing 22, the rotary bearing is arranged on the fixed block 21;

[0055] The first s...

Embodiment 2

[0091] This embodiment provides an automatic water quality sampler and its working method. The difference from Embodiment 1 is that there are two photoelectric switches in this embodiment. When the two photoelectric switches detect signals simultaneously within a period of time and the If a photoelectric switch detects the signal in advance, it is determined that the position where the signal is detected in advance is the initial position.

Embodiment 3

[0093] An application example of the water quality automatic sampler in embodiment 1 of the present invention in the field of water quality monitoring.

[0094] In this application example, the water quality automatic sampler includes a sampling pump connected in sequence, a mixing bucket, and a sample supply pump. While analyzing, the water sample is delivered to the sample retention unit through the axial positioning device for sample retention. The sample retention unit includes at least two sample retention bottles, and the at least two sample retention bottles are placed on the rotary positioning device. There are multiple slits (such as 25) on the code wheel of the rotary positioning device, including 1 characteristic slit, and the rest are ordinary slits. On the rotary positioning device and at the position corresponding to each slit, there are reserved samples bottle; the axial positioning device is provided with a sample retention / cleaning position and an emptying pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com