A pressure pulsation attenuation device with adjustable attenuation frequency integrated in the plunger pump

A technology for attenuating frequency and pressure pulsation, which is applied to components, pump elements, machines/engines, etc. of elastic fluid pumping devices, and can solve the problems of ineffective attenuation of pressure pulsation and hydraulic pump source pressure pulsation, etc., to improve Space utilization, adjustable attenuation frequency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings and embodiments:

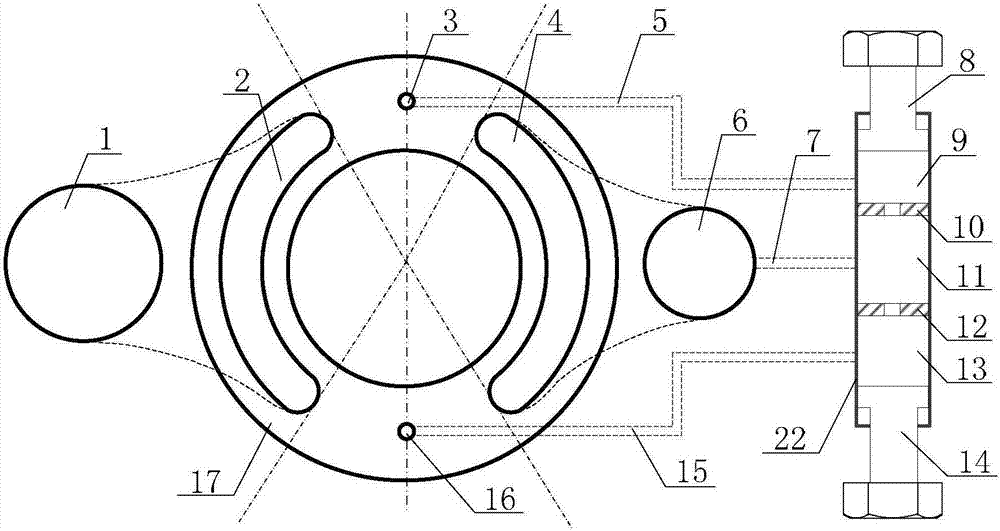

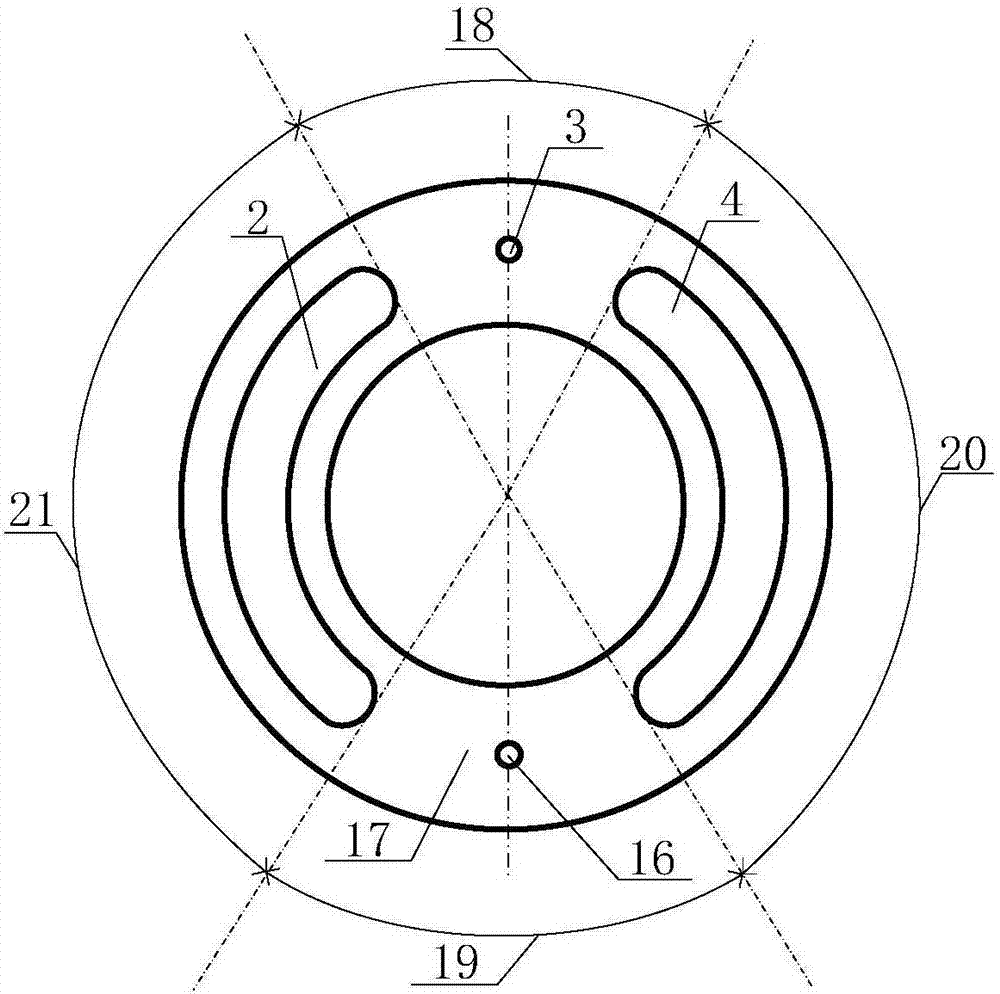

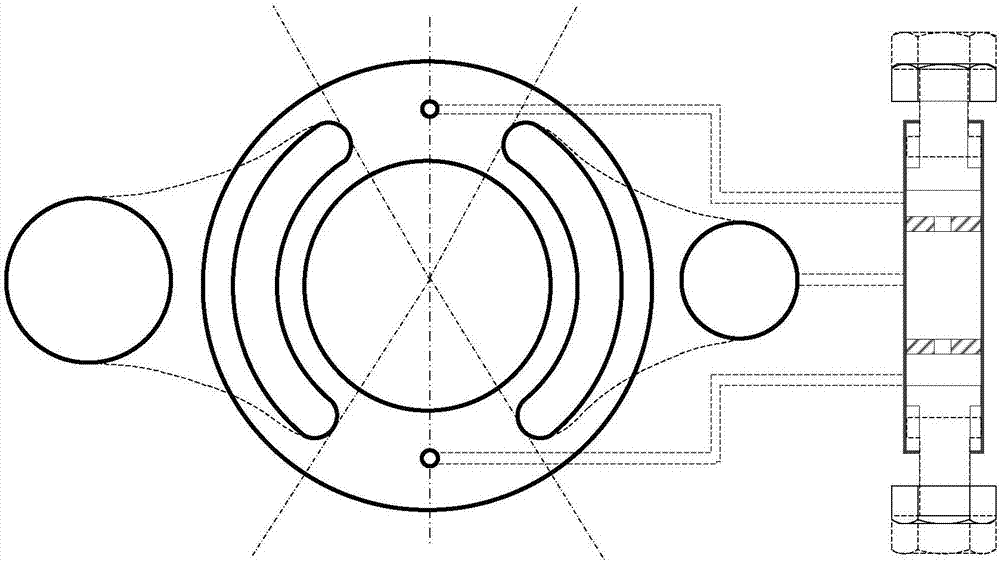

[0023] The plunger pump includes an oil suction port 1, an oil suction groove 2, an oil discharge groove 4, and an oil discharge port 6. The oil suction groove 2 and the oil discharge groove 4 are arranged on the valve plate 17, and the present invention is arranged and connected to the valve plate 17 of the plunger pump. Such as figure 1 As shown, it specifically includes a top dead center pressure buffer mechanism, an oil drain buffer mechanism, and a bottom dead center pressure buffer mechanism. The top dead center pressure buffer mechanism includes a top dead center orifice 3, an upper thin tube 5, an upper buffer cavity 9, and an upper adjustment The nut 8 and the through hole of the upper hole damping sheet 10, the bottom dead center pressure buffer mechanism includes the bottom dead center damping hole 16, the lower thin tube 15, the lower buffer cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com