Oven hinge with two-way buffering function

A two-way buffering and functional technology, applied in the field of oven hinges, can solve problems such as high production costs, vibration, and cumbersome installation, and achieve the effects of improving market competitiveness, improving operating quality, and running quietly and smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

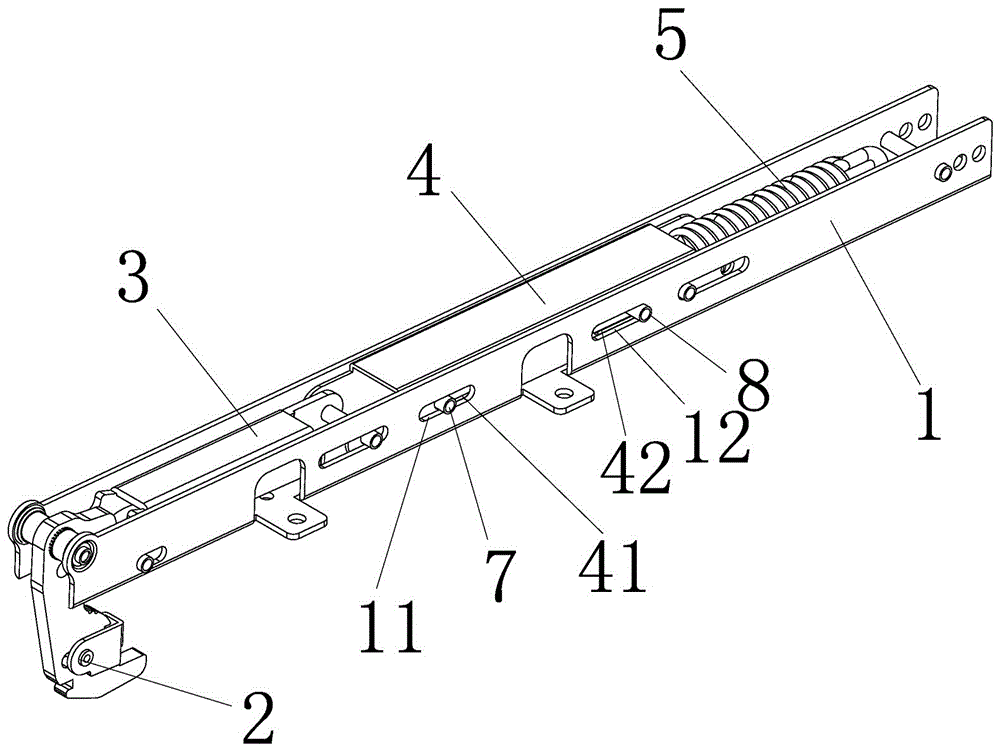

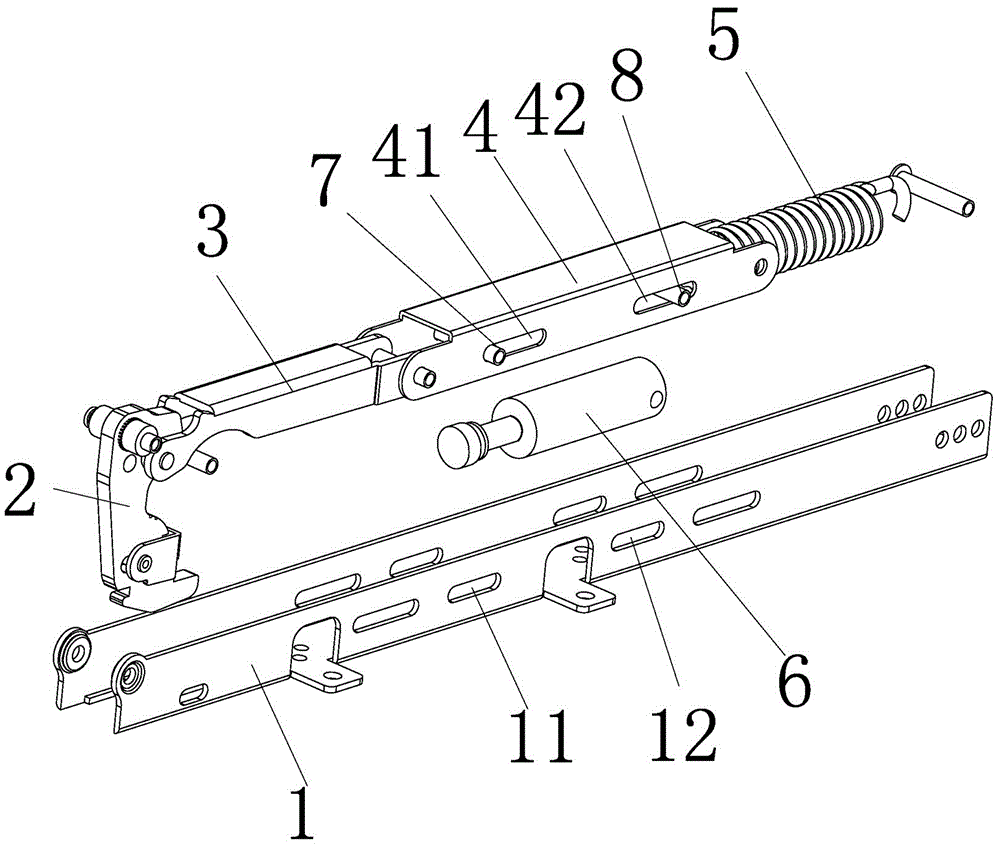

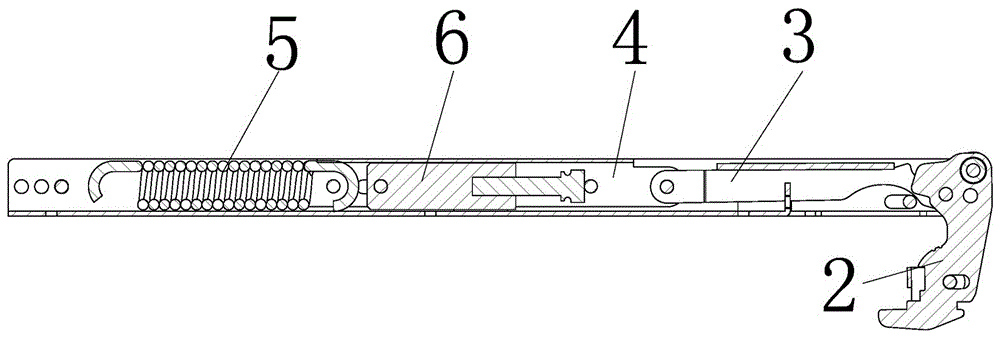

[0021] The present invention will be specifically and further described below in conjunction with the accompanying drawings. An oven hinge with two-way buffering function, which includes a main casing 1 and a hinge arm 2 arranged at its end, the hinge arm 2 is hingedly mounted on the main casing 1 in a swingable manner, and inside the main casing 1 The first pull arm 3 is also installed, the front end of the first pull arm 3 is hinged with the hinge arm 2, the rear end of the first pull arm 3 is hinged with the second pull arm 4, and the tail end of the second pull arm 4 is connected with the main housing 1. A tension spring 5 is provided, and the tension spring 5 generates tension to drive the hinge arm 2 to rotate inwards through the first and second tension arms 3 and 4 to generate the power to close the door. It is characterized in that: the main housing 1 is also provided with a buffer 6, the front end of the buffer 6 is equipped with a first connecting rod 7, the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com