A method for drawing double cones of preform rods

A prefabricated rod and rod diameter technology, which is applied in the direction of manufacturing tools, glass forming, glass manufacturing equipment, etc., can solve the problems of waste of raw materials, complicated process, low efficiency, etc., achieve the effect of small stress on the cone head and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding of the present invention, the present invention will be described in further detail below. This embodiment is only used to explain the present invention and does not constitute a limitation on the protection scope of the present invention.

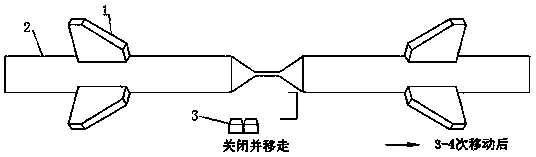

[0017] Since the size of the preforms are currently developing in the direction of thicker and longer, and the diameter of the preforms have basically reached 150-200mm, in order to make the preforms better heat, the heat of the tapered part is more uniform, reducing the The internal stress caused by uneven heat when pulling the cone adopts the combustion method of propane and oxygen, and the gas ratio is propane: oxygen volume ratio = 60:250.

[0018] The method for drawing a double cone of a preform of the present invention includes the following steps:

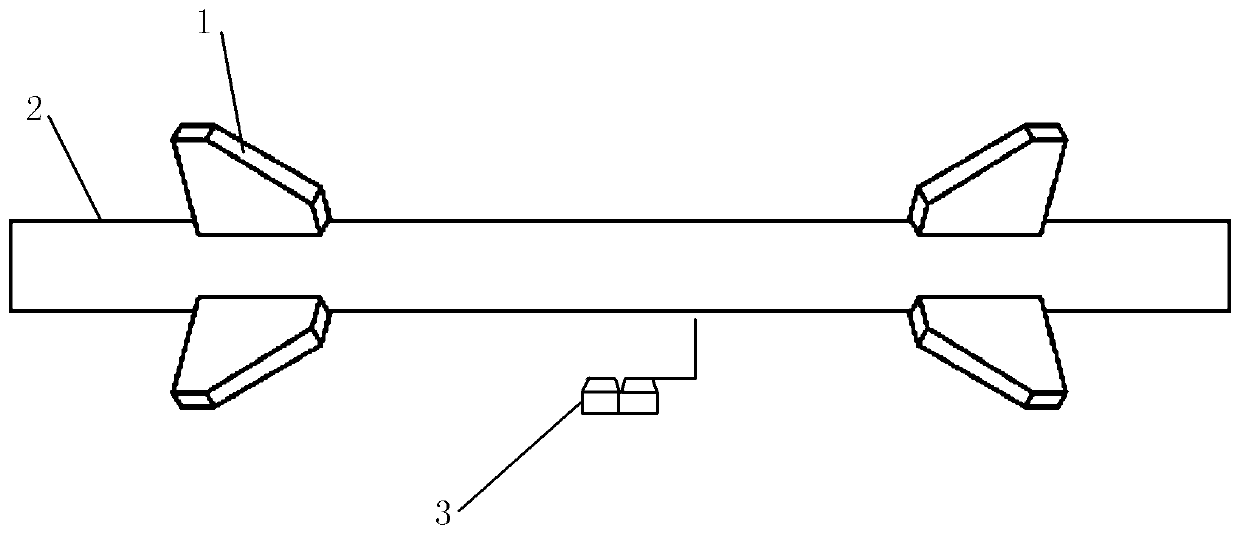

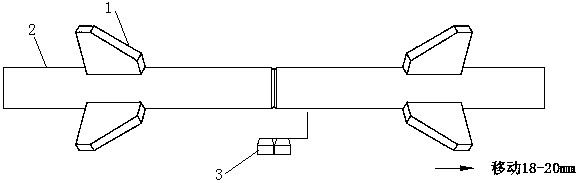

[0019] (1) figure 1 As shown, the preheating process: first clamp the preform 2 to the claws 1 at both ends, confirm the level of the preform, align...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com