ICT automatic supply device

An automatic feeding and equipment technology, applied in the direction of conveyor objects, transportation and packaging, conveyors, etc., can solve the problems of low degree of automation, need for manual feeding, and inability to carry out batch continuous detection, etc., to achieve high degree of automation, The effect of improving detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] The directional terms mentioned in the following embodiments, such as "horizontal, vertical, left, right", etc., are only referring to the directions of the drawings, therefore, the directional terms used are for illustration and not for limiting the practical invention.

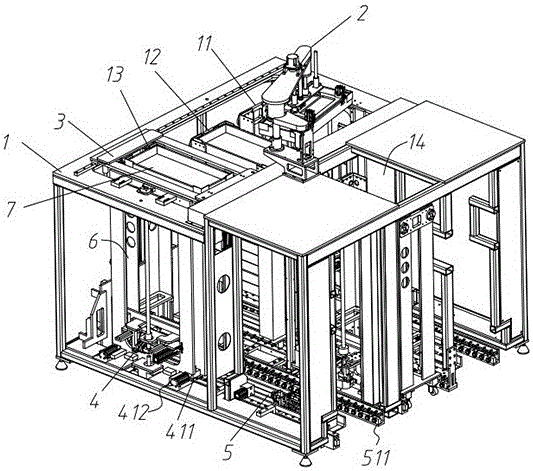

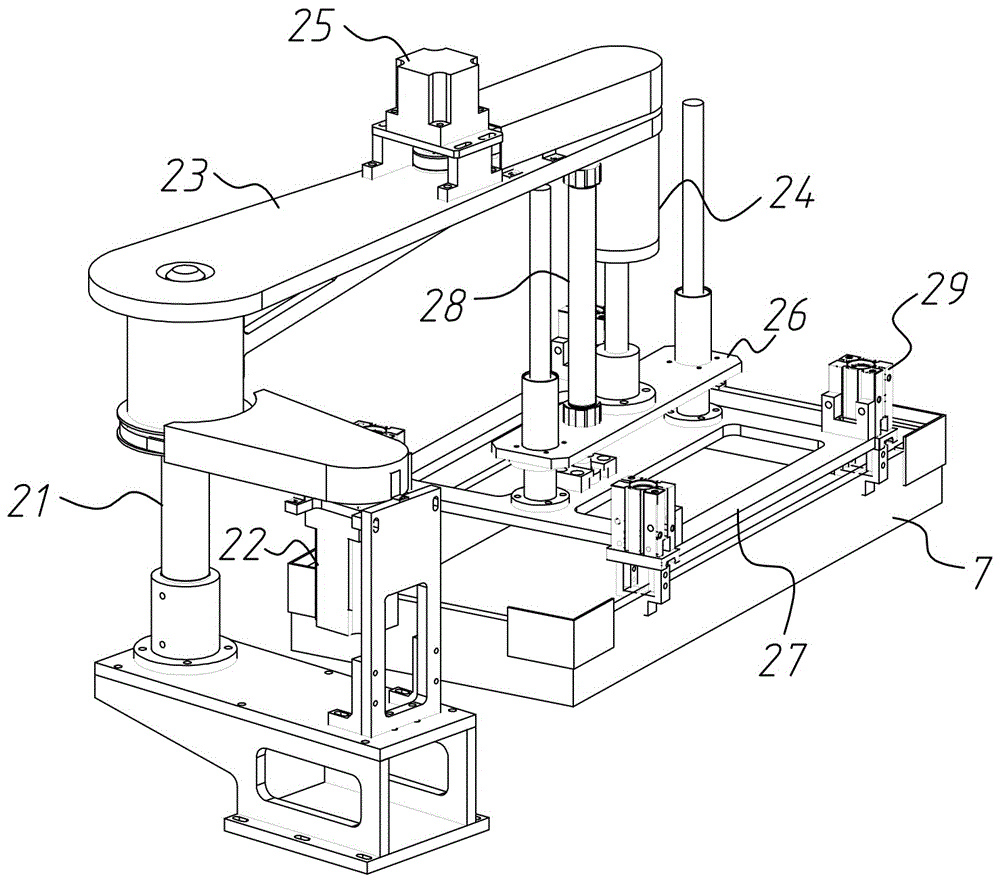

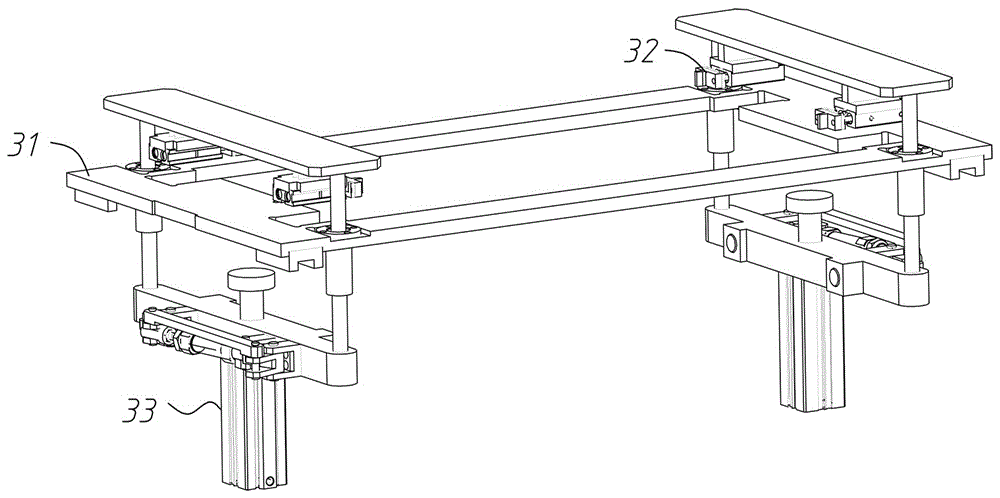

[0020] refer to Figure 1 to Figure 6 The ICT automatic feeding equipment is used for ICT automatic sorting and feeding test line so that the test line does not need to be manually fed during the test process to improve its automation. It includes a carrying platform 1 and is installed on the carrying platform 1. The transport manipulator 2 for transporting the workpiece box 7 on the upper surface, the transfer mechanism 3 installed on the upper surface of the carrier platform 1 through the slide rail pair, the upper and lower transport mechanism 4 installed below the carrier platform 1, the traile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com