Automatic assembly equipment for small slider components

A technology of automatic assembly and small slider, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity of employees, high labor costs, and low operating efficiency, and achieve the effect of saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, the present invention will be described in detail with reference to the drawings and the embodiments. It should be noted that the following embodiments and the features in the embodiments can be combined with each other if there is no conflict.

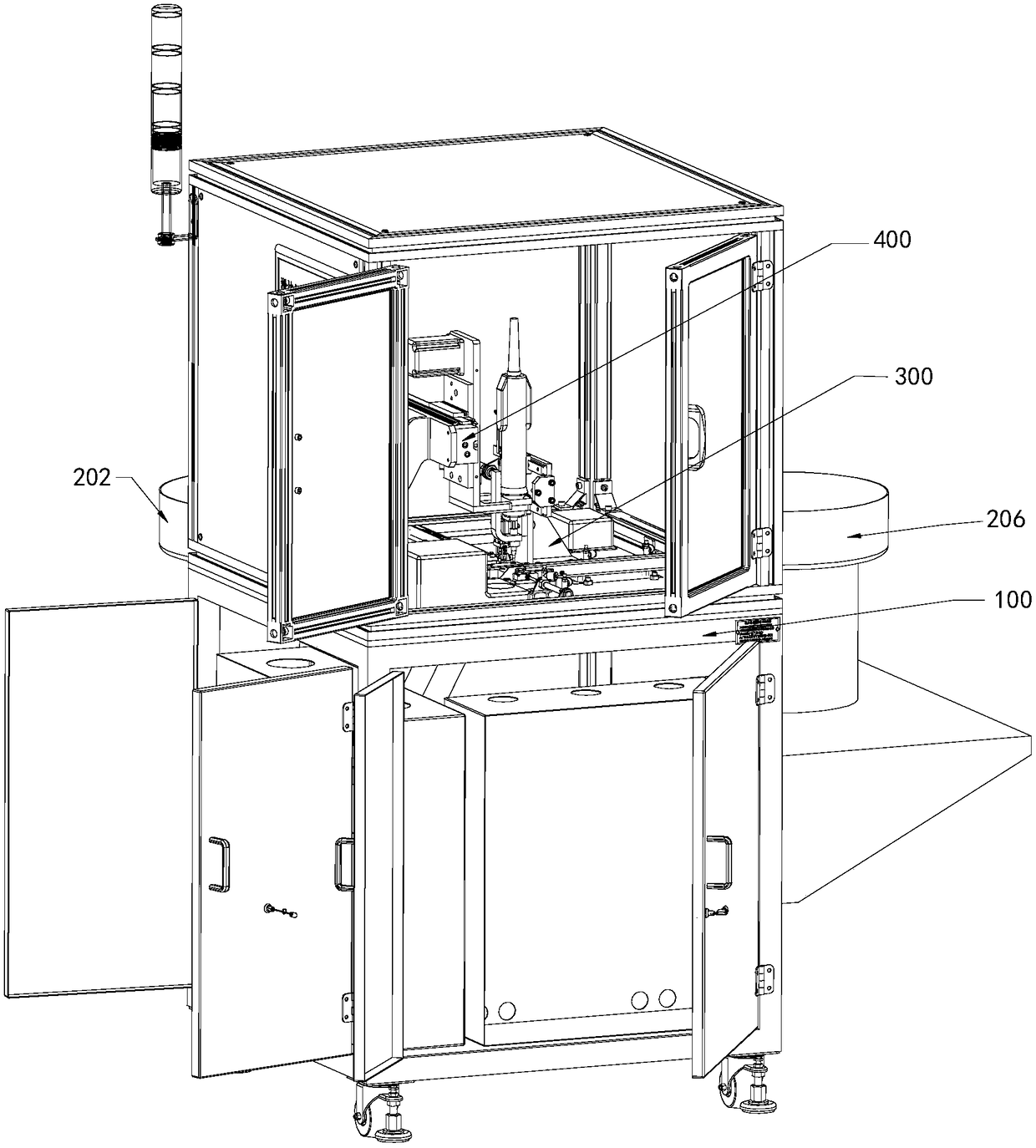

[0037] figure 2 This is a three-dimensional schematic diagram of the small slider assembly automatic assembly equipment in one of the embodiments of the present invention. As shown in the figure, the small slider assembly automatic assembly equipment mainly consists of a frame 100, a feeding system 200, and a rubber block slider assembly mechanism 300. It consists of a small slider assembly conveying mechanism, an automatic screwing mechanism 400 and a finished product blanking mechanism 500.

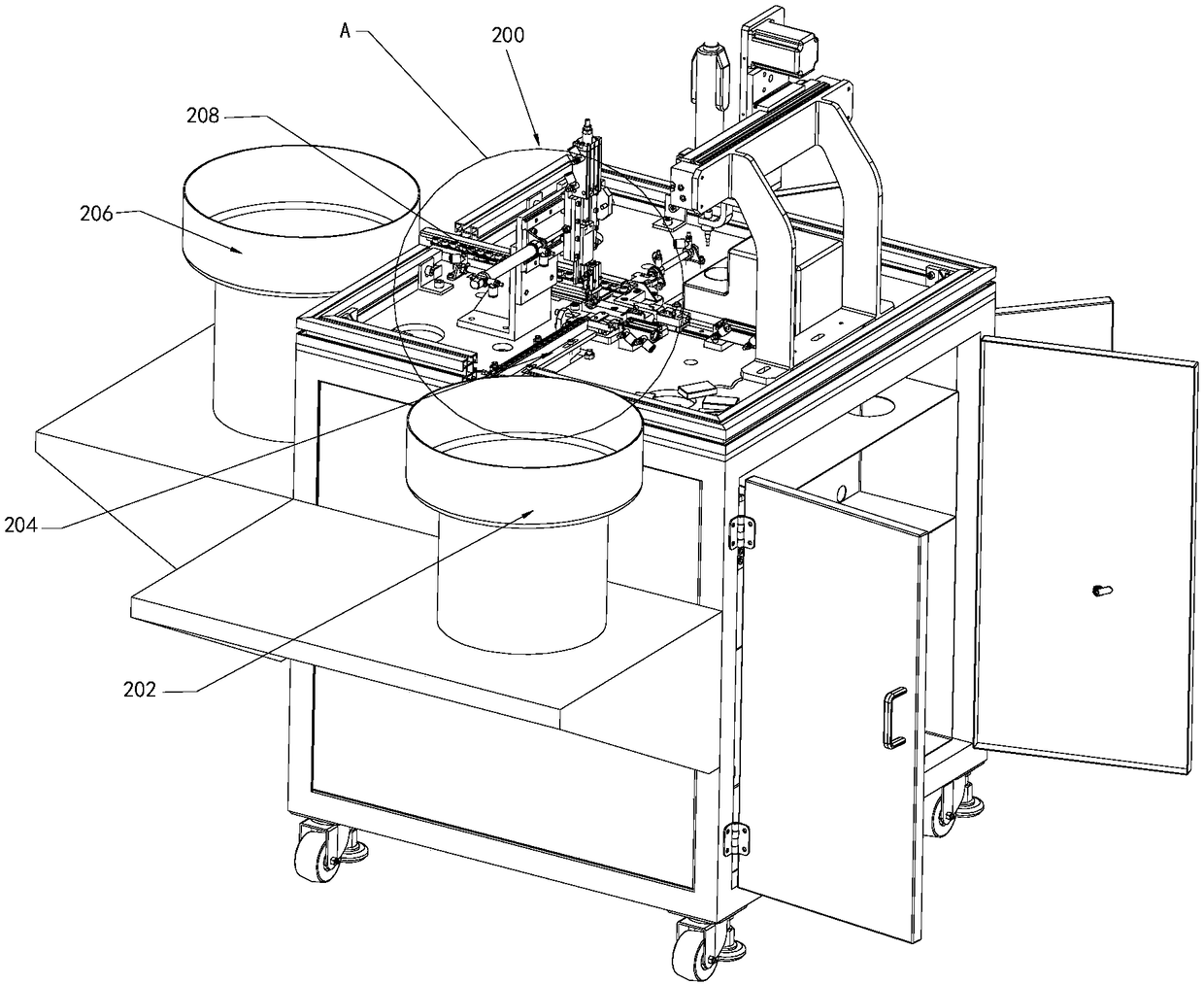

[0038] The feeding system 200 is arranged on the frame 100 and is used to transport the rubber block 12 and the sliding block 14 to the grasping position and the assembly position, respectively. Such as image 3 , 4 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com