Multi-stage solid-liquid separating equipment

A solid-liquid separation and equipment technology, which is applied in the field of solid-liquid separation equipment, can solve the problems that the gap between the screen bars cannot be adjusted, the dry humidity of the filter residue cannot be adjusted well, and the cost is high, so as to improve the anti-backflow performance and filtration performance, fine Solid-liquid separation effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

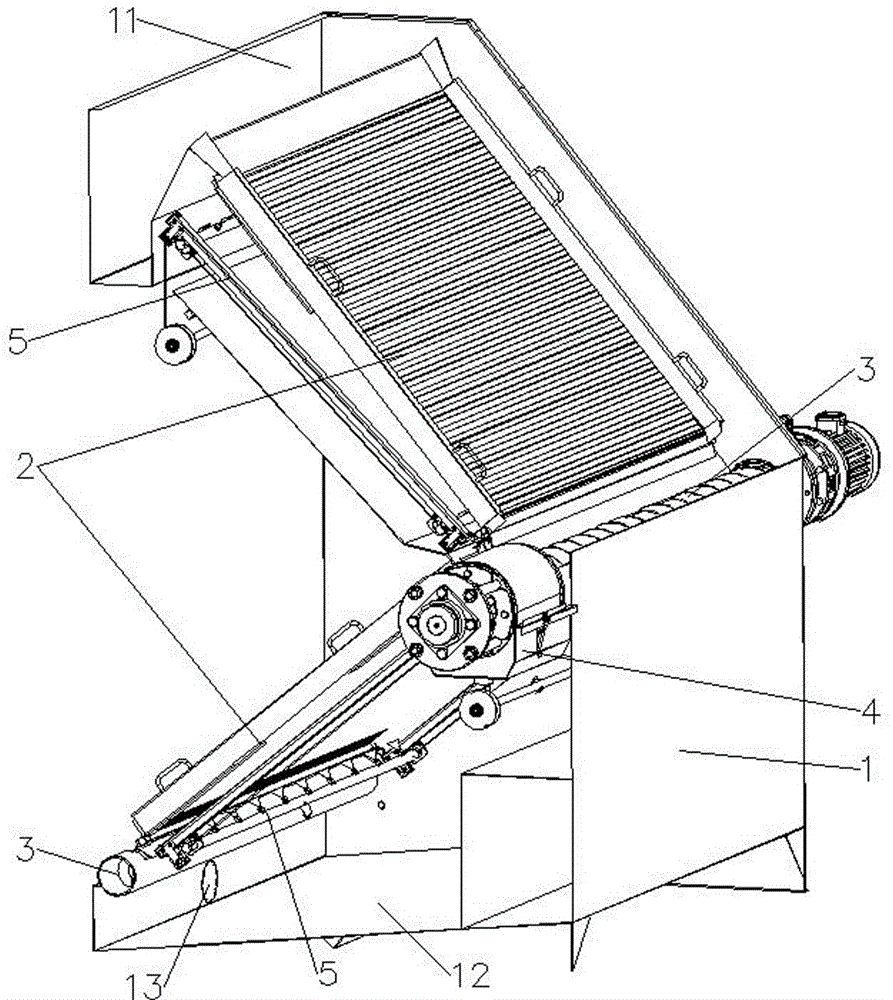

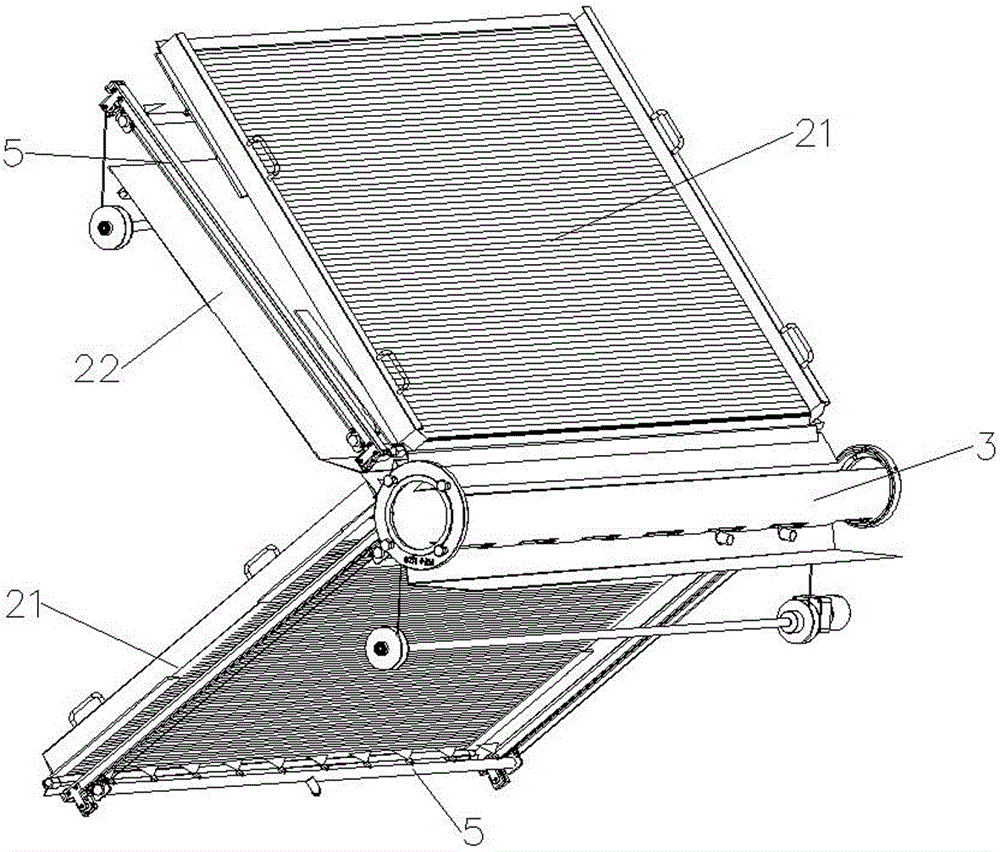

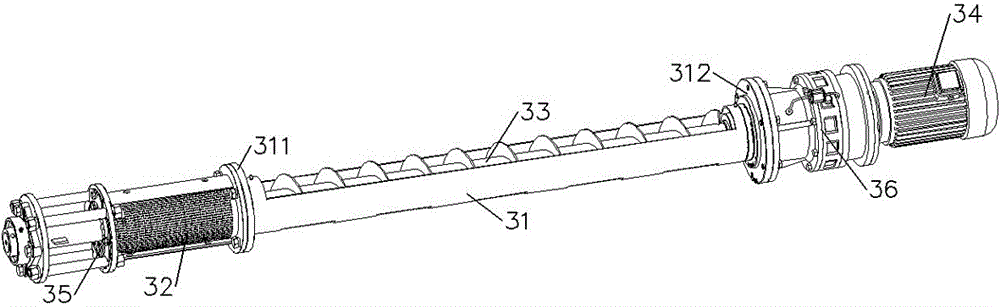

[0032] like figure 1 and 2 As shown, a multi-stage solid-liquid separation device includes a casing 1 and a multi-stage screen filter mechanism 2 arranged in the casing 1 and a plurality of screw extrusion solid-liquid separation mechanisms 3; the casing 1 A waste water tank 12 provided with a feed inlet 11 and a bottom, the waste water tank 12 has a water outlet 13; the feed end of the first stage screen 21 of the multi-stage screen filter mechanism 2 is arranged on the casing 1 At the feed port 11 of the feed port, a screw extrusion solid-liquid separation mechanism 3 is provided at the discharge end of each level of screen 21; the solid material discharge ends of all screw extrusion solid-liquid separation mechanisms 3 are all arranged at the said Outside the casing 1.

[0033] The multi-stage solid-liquid separation equipment uses a multi-stage screen filter mechanism 2 and multiple screw extrusion solid-liquid separation mechanisms 3 to simultaneously filter the solid-l...

Embodiment 2

[0065] A multi-stage solid-liquid separation process, applied to the multi-stage solid-liquid separation equipment described in Example 1, the steps include:

[0066] Step 0: According to the final required dry humidity of the solid material, adjust the quantity of several elastic pressing pieces 35 on the solid material discharge end of each screw extrusion solid-liquid separation mechanism 3;

[0067] Step 1: putting the solid-liquid mixture requiring solid-liquid separation into the multi-stage solid-liquid separation equipment;

[0068] Step 2: the waste water filtered by the multi-stage screen filter mechanism 2 from the solid-liquid mixture flows into the waste water tank 12;

[0069] Wherein, said step 2 includes:

[0070] Step 2.1: The waste water in the solid-liquid mixture flows out from the gap between the screen bars 211 of the upper-level screen 21 to the water guide plate 22 below the screen 21 of this level;

[0071] Step 2.2: the waste water on the water guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com