Miniaturized vacuum ring network cabinet

A ring main unit and vacuum technology, which is applied in the setting of switchgear, electrical components, switchgear and other directions, can solve the problems of damping insulation board and insulation aging, and achieve increased creepage distance, stable grounding performance, and reliable distribution. The effect of electrical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

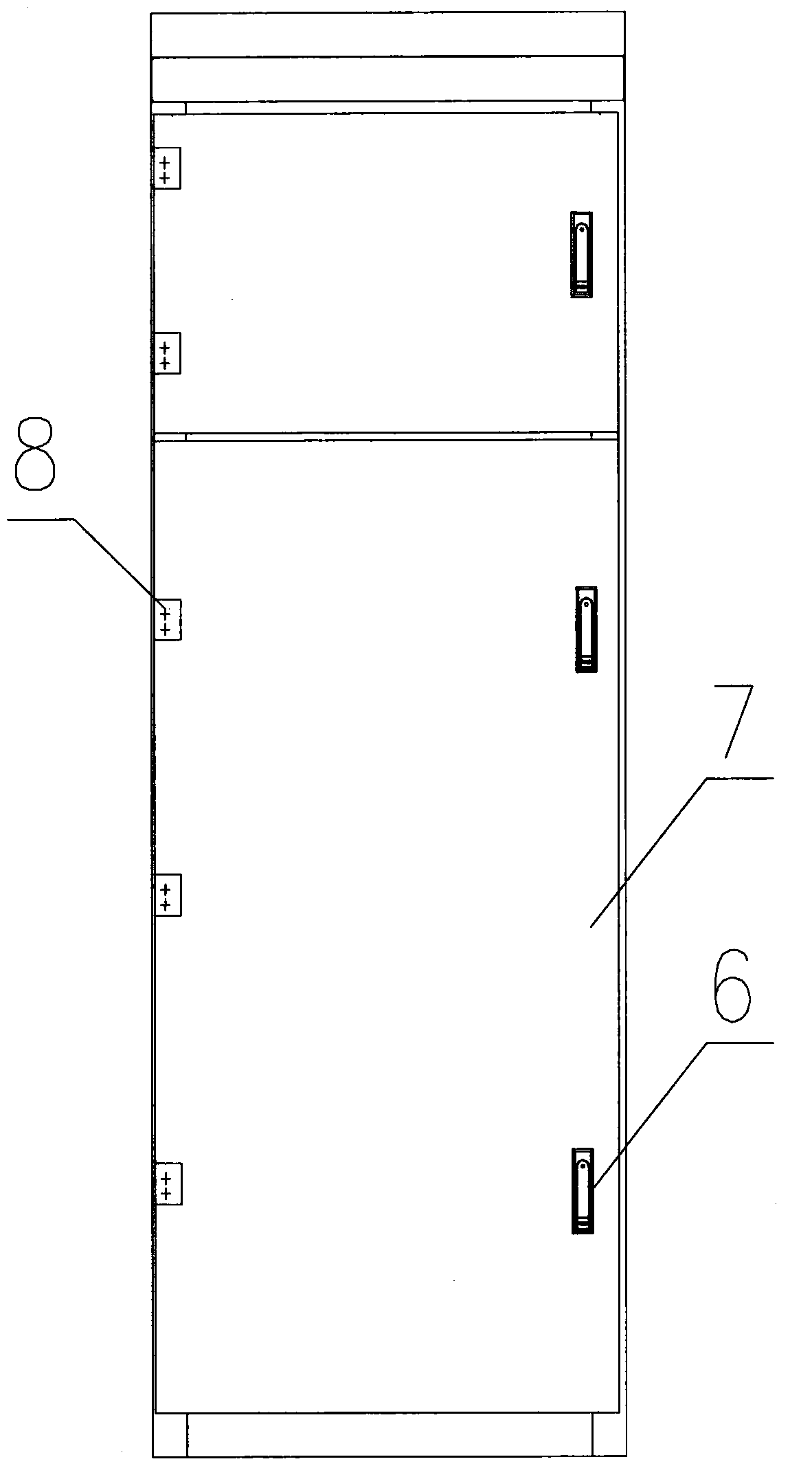

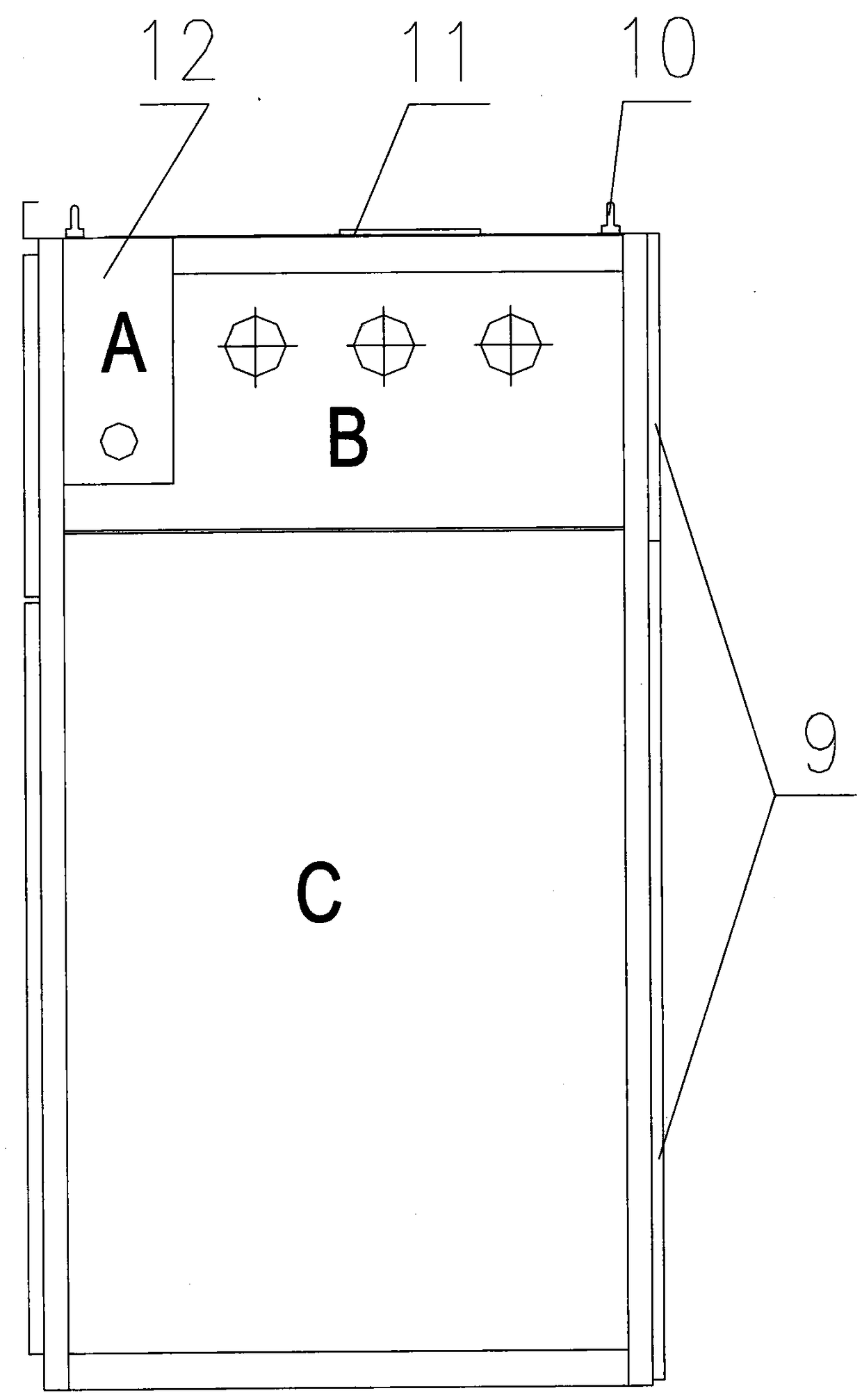

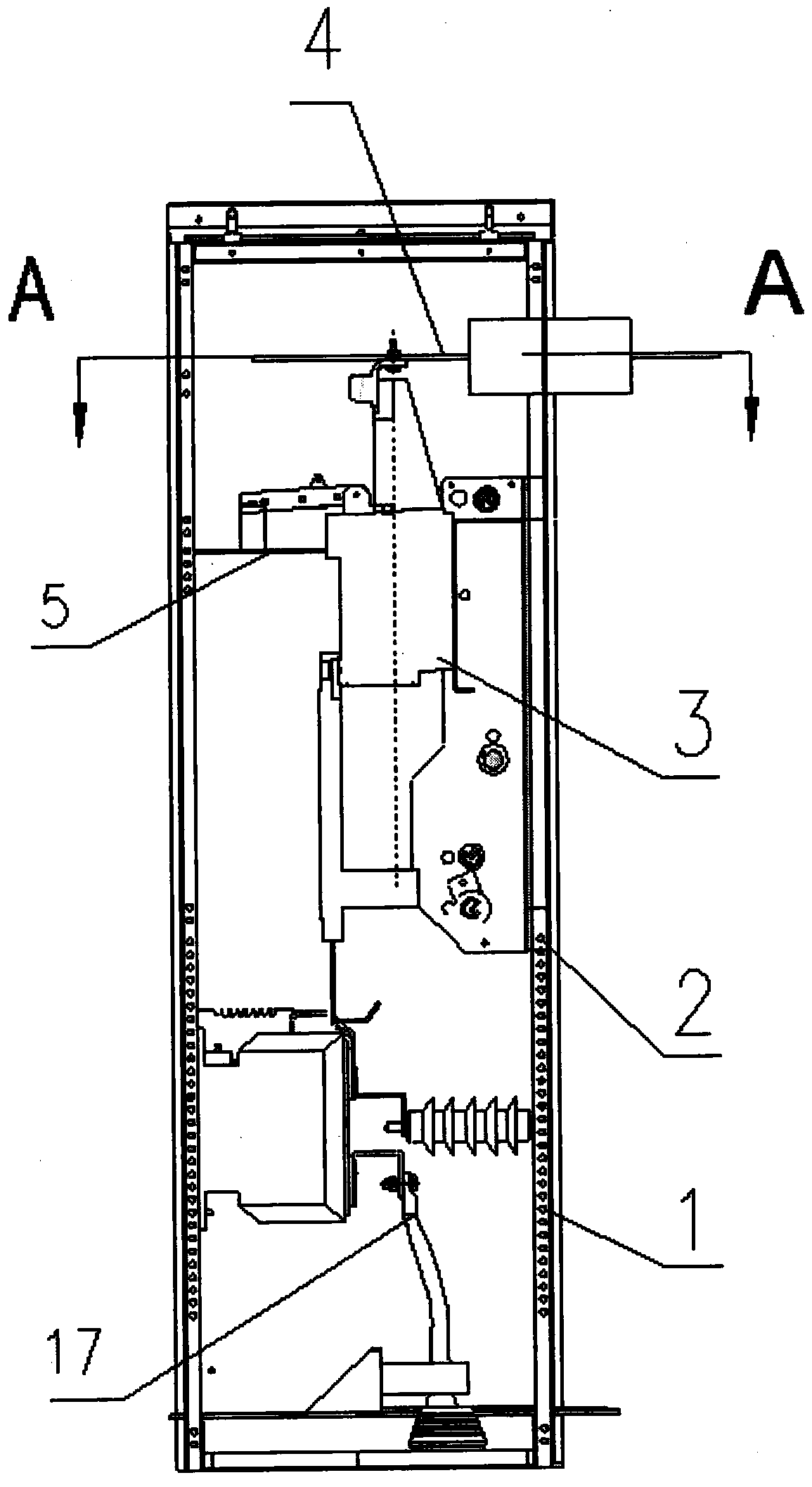

[0022] The invention is a miniaturized vacuum ring network cabinet, such as Figure 1-Figure 3 As shown, it is composed of a G-shaped housing 1, an improved vacuum switch assembly 3 and a cable connection assembly 17, a secondary element connection module 12 and a primary bus assembly 4. The internal space of G-profile housing 1 is divided into three compartments: instrument room A, bus-bar room B, and switch cable room C according to their functions. Bus-bar room B is located at the rear upper part of G-profile housing 1, and instrument room A is located in G-profile housing. At the upper front part of 1, the switch cable compartment C is located in the middle and lower part of the G-profile housing 1, and the compartments are completely separated by partitions. The partition 5 between the busbar compartment B and the switch cable c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com