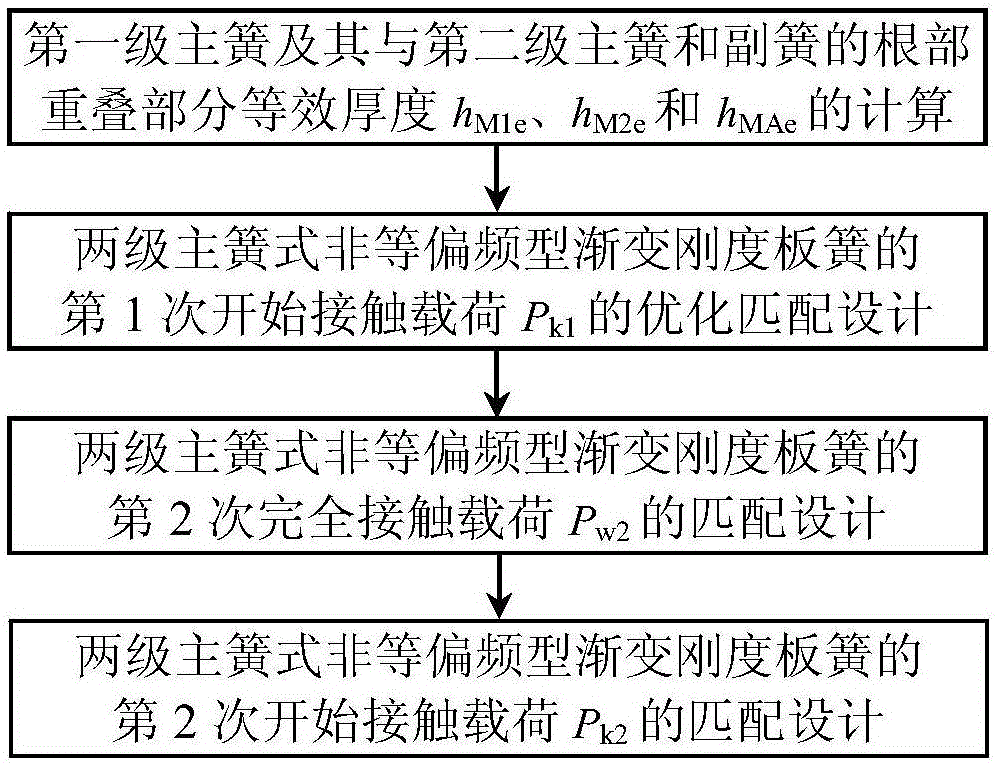

Matching design method for contact load of two-stage main spring type non-constant frequency variable grade rigidity leaf spring

A design method and main spring technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as complex deflection calculations and inability to meet higher requirements for suspension springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

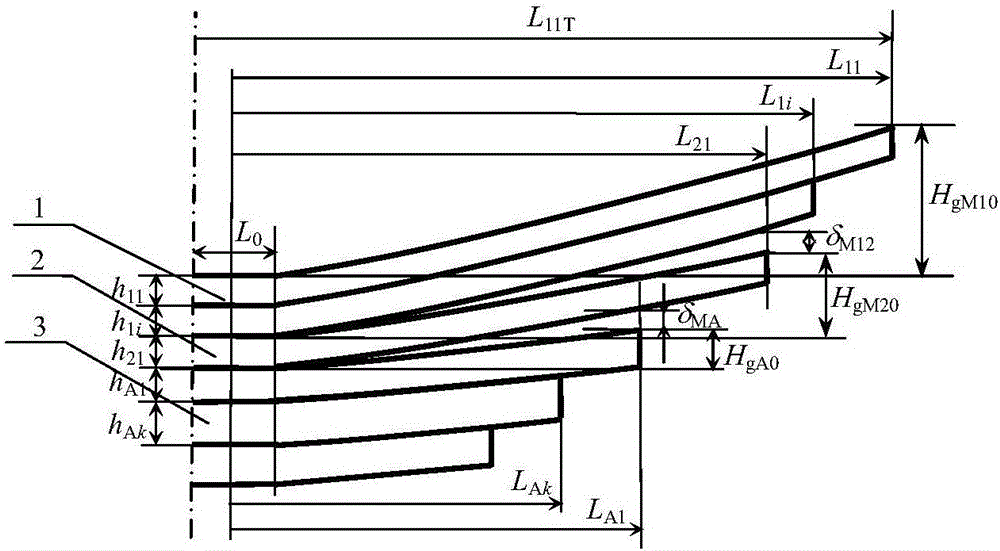

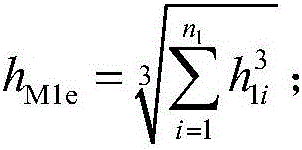

[0039] Embodiment: The width b of a certain two-stage main spring type unequal-bias frequency gradual stiffness leaf spring is 63 mm, half of the clamping distance of the saddle bolt L 0 =50mm, elastic modulus E=200GPa, allowable stress [σ]=600MPa. Number of primary reeds n 1 = 2, the thickness h of each piece of the first stage main spring 11 = h 12 =8mm, half of the working length of each leaf of the first stage main spring is L respectively 11T =525mm, L 12T =450mm; half of the clamping length is L 11 = L 11T -L 0 / 2=500mm, L 12 = L 12T -L 0 / 2=425mm. Second stage main reed number n 2 = 1 piece, thickness h 21 =8mm; Half the working length L of the second stage main spring 21T =350mm, half of the clamping length L 31 = L 21T -L 0 / 2=325mm. The number of secondary reeds m = 2 pieces, the thickness of each piece of secondary reed h A1 = h A2 =13mm; half of the working length of each piece of auxiliary spring is L A1T =250mm,L A2T =150mm; the clamping leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com