high temperature resistant 2 Foam clean associative fracturing fluid and its preparation method and application

A fracturing fluid and association technology, applied in chemical instruments and methods, earthwork drilling and production, wellbore/well components, etc., can solve the problem of difficult control of crosslinking performance stability, unsuitability for medium and high temperature reservoirs, cost and durability It can effectively delay the crosslinking effect, facilitate the preparation, and reduce the viscosity of the base fluid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

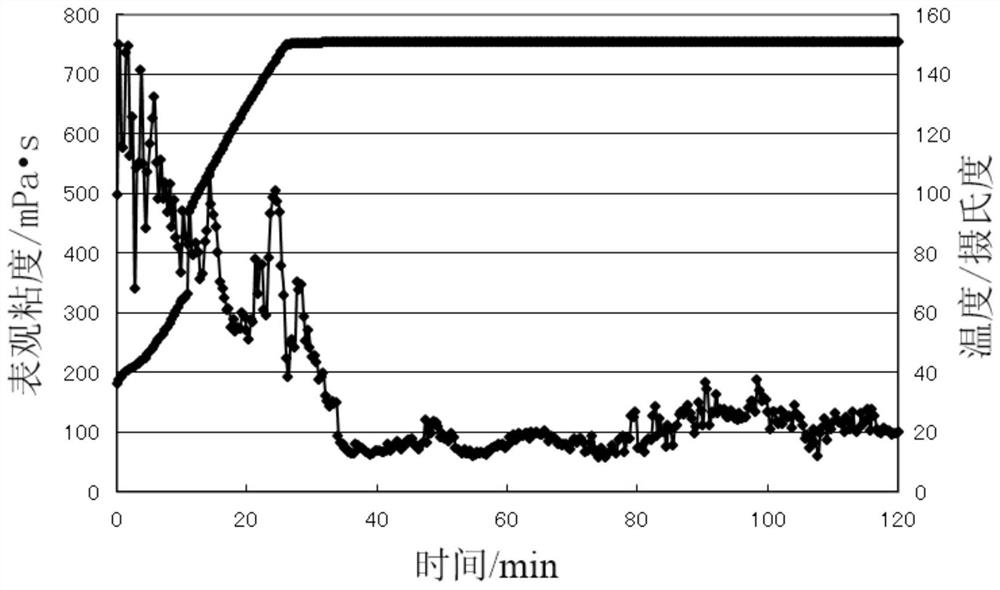

Image

Examples

Embodiment 1

[0059] This embodiment provides a fracturing fluid base fluid A, calculated on the basis of the total weight of the fracturing fluid base fluid as 100%, comprising:

[0060] 0.25% thickener;

[0061] 0.5% foaming agent;

[0062] 0.2% crosslinking regulator;

[0063] and the balance of water;

[0064] Wherein, the mass percentage of each monomer component of the thickener: 15% of acrylamide monomer, 4% of N-vinylpyrrolidone, 3% of polydiene dimethyl ammonium chloride, 7% of acrylic acid, persulfuric acid Ammonium is 0.05%, sodium acetate is 0.04%, and the rest is water.

[0065] The preparation method of this thickening agent comprises the following steps:

[0066] The reaction conditions of ternary copolymerization were used to synthesize, and nitrogen was used to remove oxygen. The reaction temperature was 55℃, and the reaction time was 4h. After the reaction is completed, the polymerized product is dried, granulated, and pulverized into a desired mesh to prepare a fract...

Embodiment 2

[0071] The present embodiment provides a fracturing fluid base fluid B, which includes:

[0072] 0.4% thickener;

[0073] 0.5% foaming agent;

[0074] 0.3% crosslinking regulator;

[0075] and the balance of water;

[0076] Wherein, the mass percentage of each monomer component of the thickener: 17% of acrylamide monomer, 3% of N-vinylpyrrolidone, 5% of alkyl methacrylate, 6% of sodium p-styrene sulfonate, Ammonium persulfate is 0.08%, sodium acetate is 0.04%, and the rest is water.

[0077] The preparation method of this thickening agent comprises the following steps:

[0078] The reaction conditions of ternary copolymerization were used to synthesize, and nitrogen was used to remove oxygen. The reaction temperature was 55℃, and the reaction time was 4h. After the reaction is completed, the polymerized product is dried, granulated, and pulverized into a desired mesh to prepare a fracturing fluid thickener. When the concentration of the thickener was 0.4%, the viscosity ...

Embodiment 3

[0082] The present embodiment provides a fracturing fluid base fluid C, which includes:

[0083] 0.6% thickener;

[0084] 0.5% foaming agent;

[0085] 0.5% crosslinking regulator;

[0086] and the balance of water;

[0087] Among them, the mass percentage of each monomer component of the thickener: 21% of acrylamide monomer, 5% of N-tris(hydroxymethyl)methyl-acrylamide, 5% of polydiene dimethyl ammonium chloride, 2-Acrylamido-2-methyl-1-propanesulfonic acid is 7%, potassium thiosulfate is 0.06%, sodium acetate is 0.03%, and the rest is water.

[0088] The preparation method of this thickening agent comprises the following steps:

[0089] The reaction conditions of ternary copolymerization were used to synthesize, and nitrogen was used to remove oxygen. The reaction temperature was 60℃, and the reaction time was 4h. After the reaction is completed, the polymerized product is dried, granulated, and pulverized into a desired mesh to prepare a fracturing fluid thickener.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com