Roller feeding device

A roller and lifting device technology, which is applied in the field of roller feeding devices, can solve problems such as unsmooth feeding, easy scratching of rollers, and affecting the appearance quality of rollers, so as to achieve smooth feeding and no damage to the feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

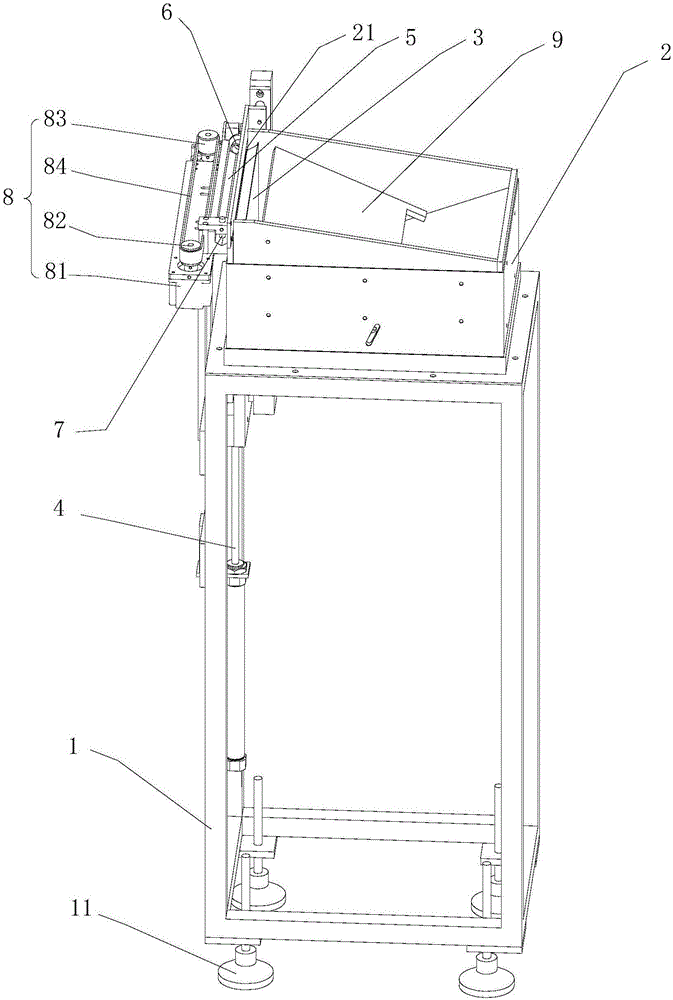

[0019] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and through specific embodiments.

[0020] like figure 1 As shown, a roller feeding device includes a frame 1, and the top of the frame 1 is fixedly connected with a silo 2; the side top of the silo 2 is provided with a discharge port 21, and the height direction of the discharge port 21 can only be Through a roller; the side of the outlet 21 facing the silo 2 is provided with a jacking mechanism, which lifts up the roller in the silo 2, and the roller moves vertically upward along one side of the silo 2 To the discharge port 21; the other side of the discharge port 21 is connected with the material channel 5 for receiving the rollers; it also includes a dial connected to the frame 1 and used to pull the rollers in the material channel 5 away from the material channel 5 material organization.

[0021] The roller feeding device proposed by the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com