Non-pneumatic inner tire

A non-pneumatic inner tube and inner tube technology, which is applied in the direction of non-pneumatic tires, tire measurement, bicycle tires, etc., can solve the problems of reduced comfort and stability, abnormal driving of vehicles, damaged tires, etc., and achieve outstanding bearing capacity and anti-seismic performance , Low glass transition temperature, increase the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

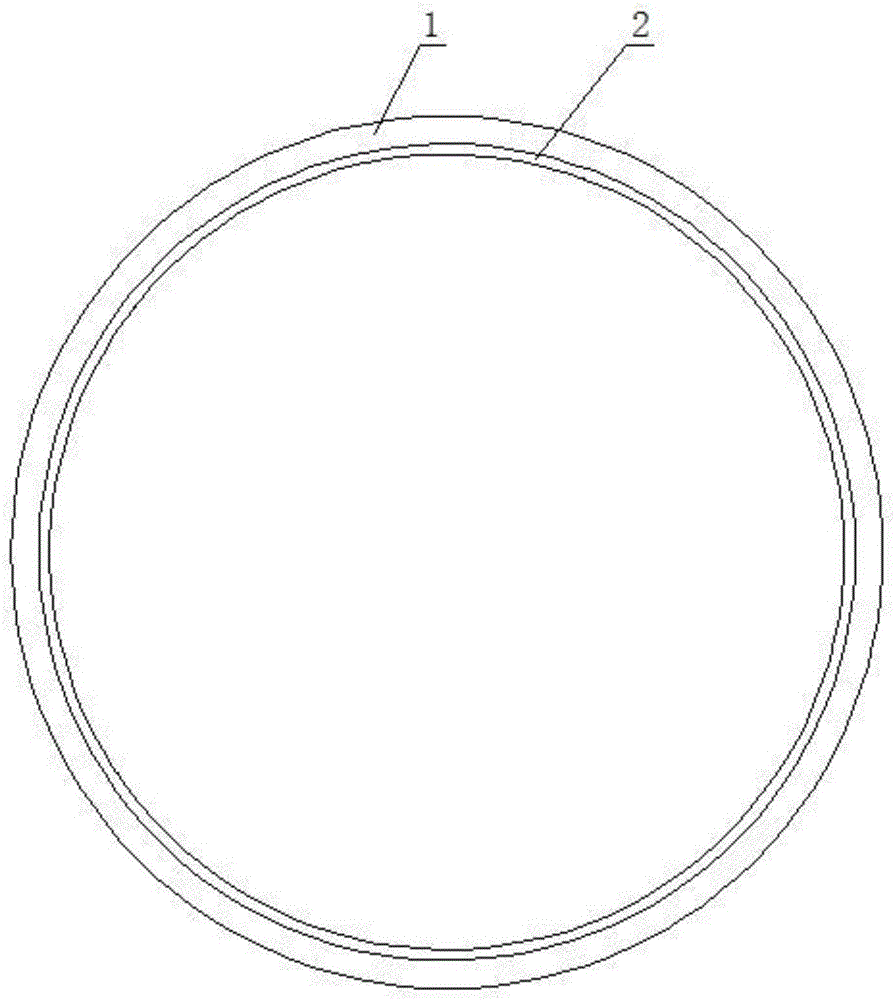

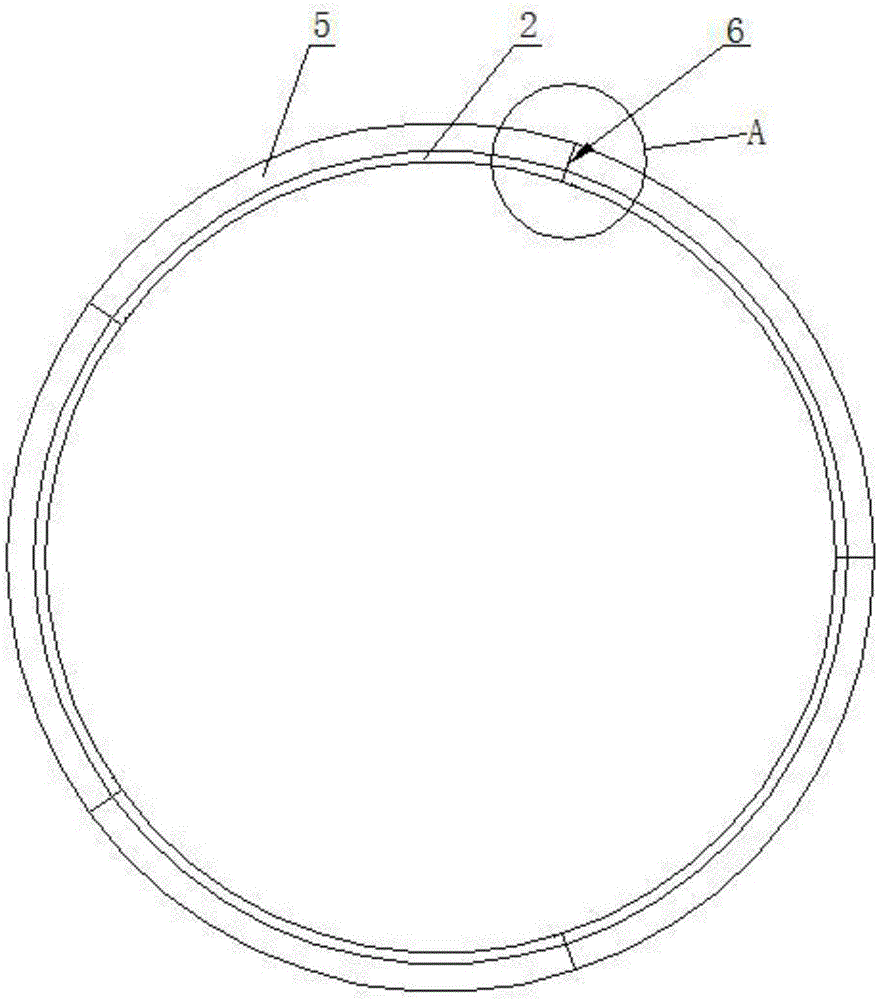

[0043] An air-free inner tube. The innovation of the present invention is that it includes an inner tube. The side of the inner tube radially away from the rim is set as a support part 1. The support part in the radial section of the inner tube is a superior arc, and the two sides of the superior arc are along the The fixing part 2 is integrally formed by extending inwardly in the tangential direction, and the curved tube of the inner tube is made of elastomer material.

[0044] In this embodiment, the elastomer material is TPU.

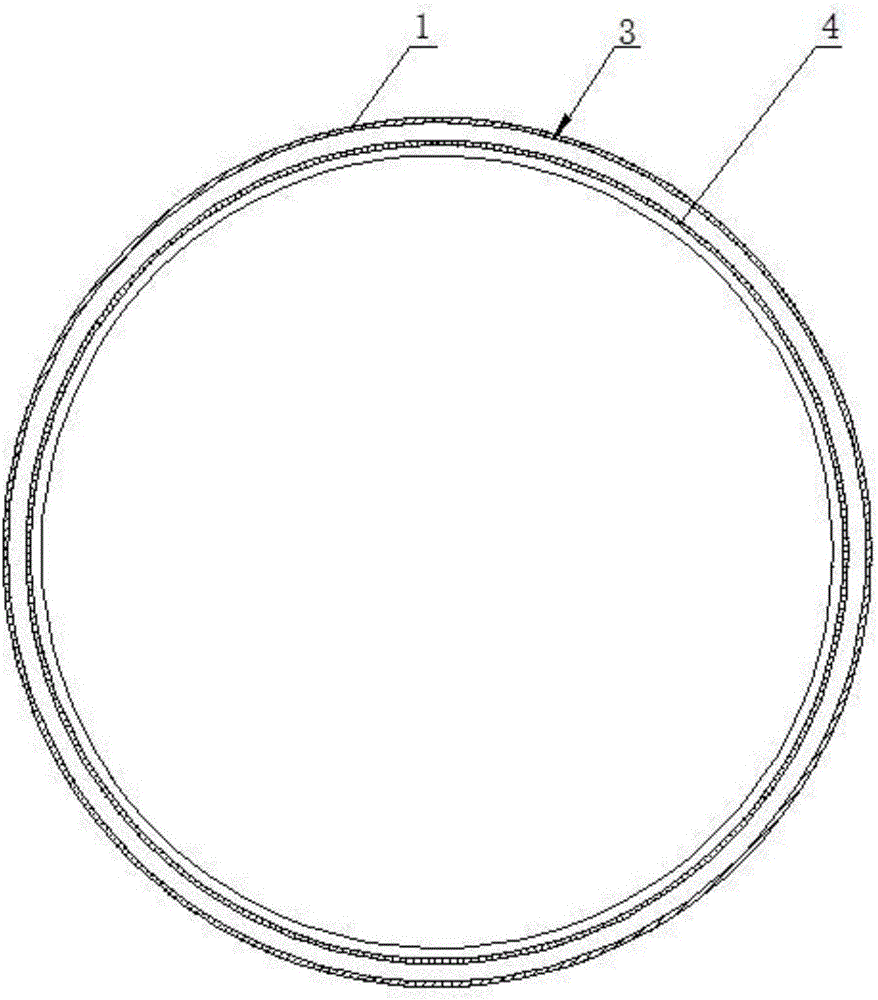

[0045] In this embodiment, the supporting portion of the inner tube is hollow inside, and an air channel 3 is formed along the extending direction of the inner tube.

[0046] In this embodiment, a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com