Automatic press-mounting machine for automobile oil pipe

A technology for pressing machine and oil pipe, applied in the field of automatic oil pipe pressing machine for automobiles, can solve the problems of time-consuming and laborious pressing and low production efficiency, and achieve the effects of ensuring accuracy and stability, reducing labor costs and continuous adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

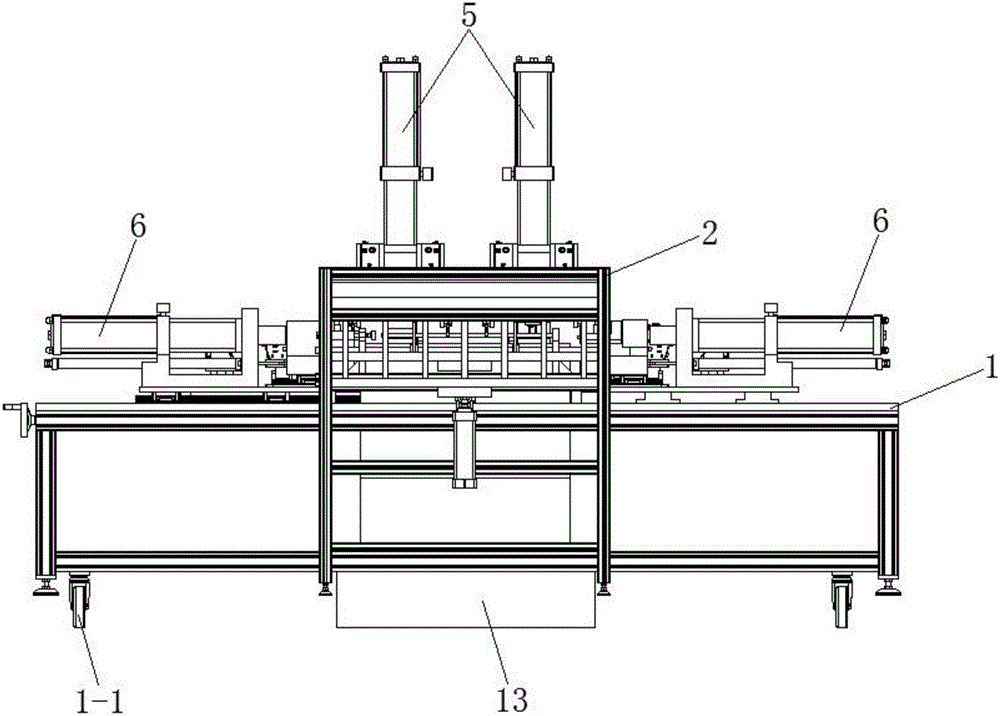

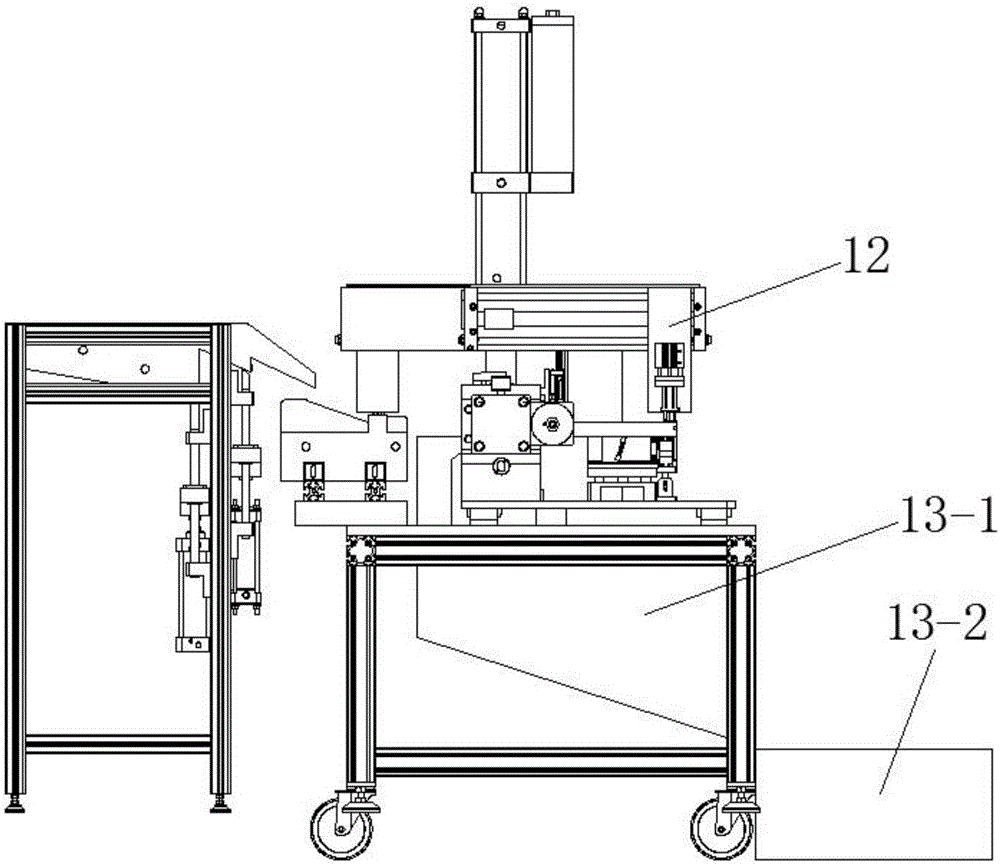

[0035] See Figure 2 to Figure 10 , the automobile tubing automatic press-fitting machine of the present embodiment comprises a workbench 1, a pipe material automatic feeding mechanism 2, a pipe material positioning tool 3, a pipe material feeding manipulator 4, a vertical booster cylinder 5, a horizontal booster cylinder 6, Slide rail 7, sliding support 8, ball head positioning tooling 9, corner pressing cylinder 10, vibrating plate 11, ball head feeding manipulator 12, feeding mechanism 13 and deflection drive device 14.

[0036]The bottom of the workbench 1 is provided with rollers 1-1. The pipe material automatic feeding mechanism 2 is arranged on the front side of the workbench 1 . Pipe material positioning tool 3, pipe material feeding manipulator 4, vertical pressurized cylinder 5, horizontal pressurized cylinder 6, slide rail 7, sliding support 8, ball head positioning tool 9, corner pressing cylinder 10, vibration plate 11 There are two feeding manipulators 12 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com