Self-washing centrifugal screen filter

A centrifugal net and self-flushing technology, applied in the filter field, can solve problems such as insufficient swirling angle and speed of the centrifugal part, regular cleaning, complex structure, etc., to increase the effect of centrifugal filtration, protect water pumps and pipelines, and increase the filtration area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

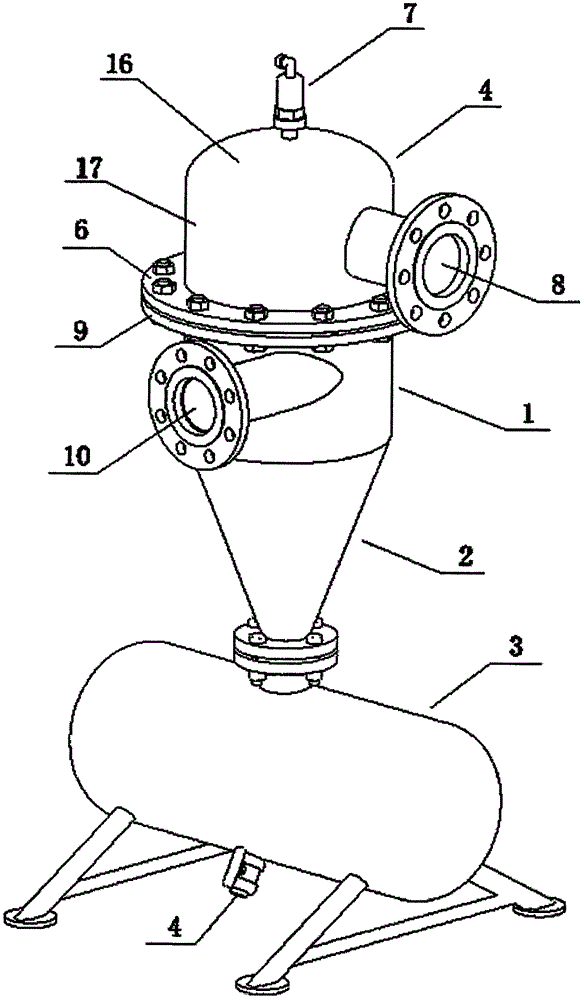

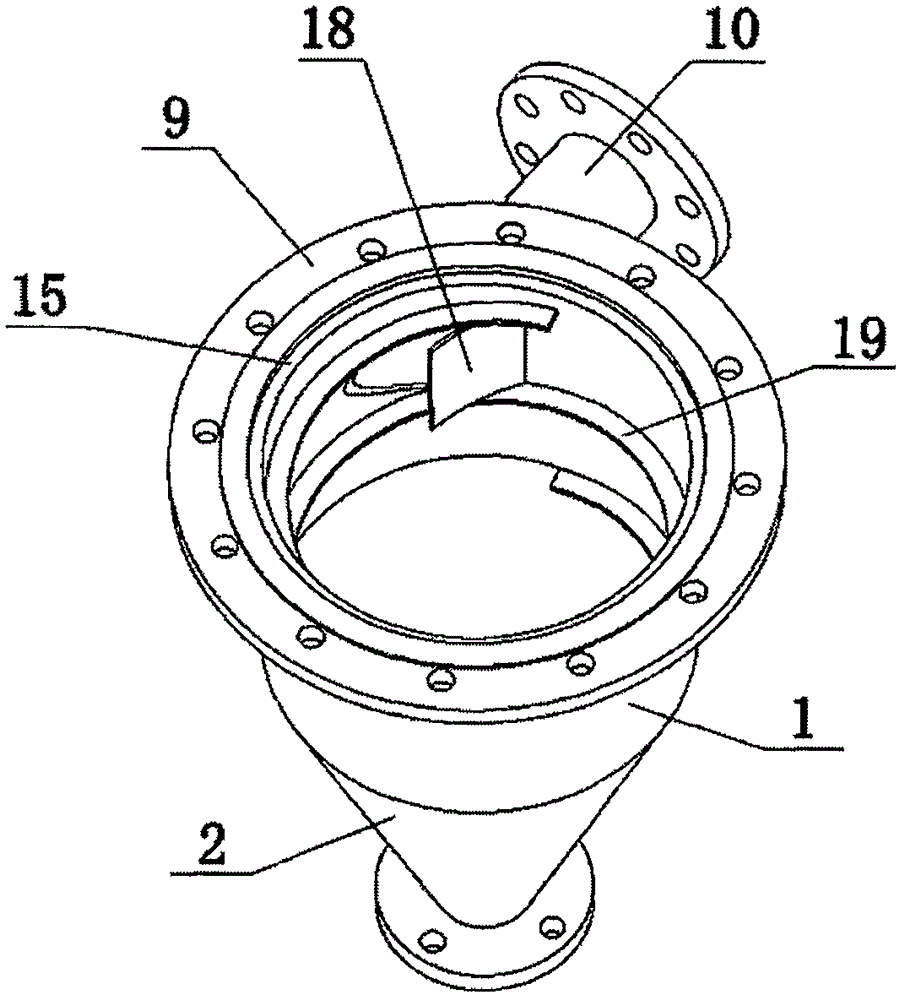

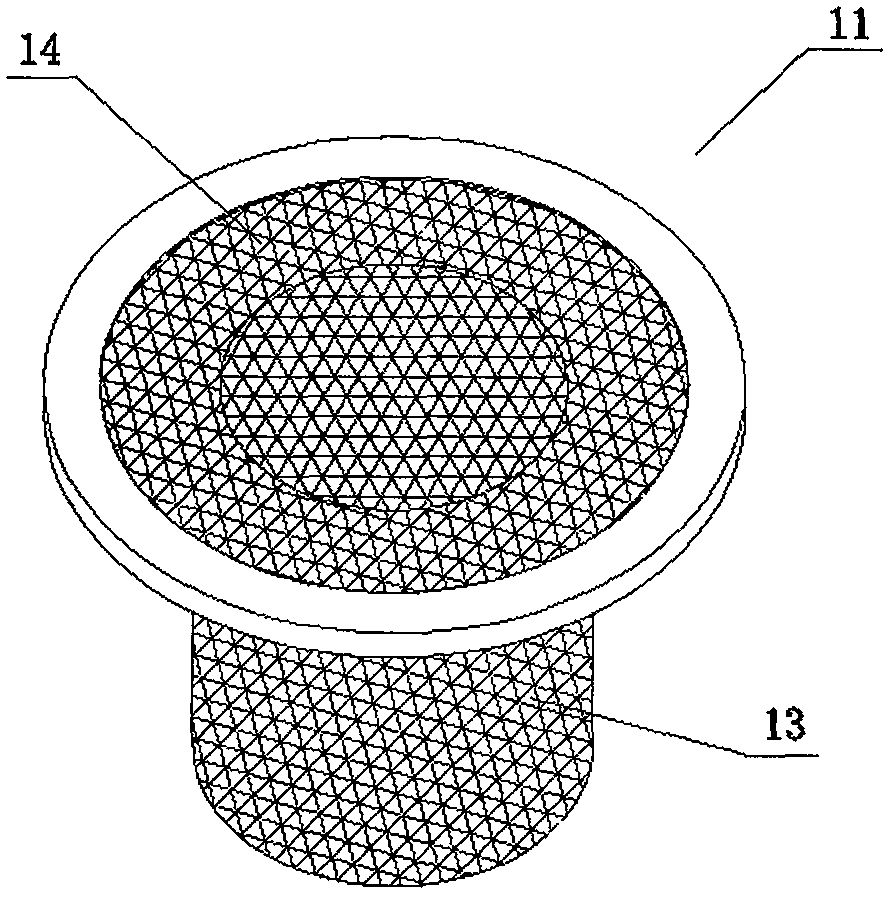

[0023] like figure 1 , figure 2 , image 3 and Figure 4 Shown, a kind of self-rinsing centrifugal screen filter, it comprises cyclone cylinder 1, the conical separation cylinder 2 of cyclone cylinder 1 bottom, the grit chamber 3 of conical separation cylinder 2 bottom, grit chamber 3 is provided with The sewage pipe 4 is provided with a water collecting cap 5 on the upper part of the cyclone 1. The upper end of the water collecting cap 5 is a spherical cover 16, and the center of the spherical cover 16 is provided with an intake and exhaust valve 7. The lower part of the spherical cover 16 is a cylindrical side The wall 17, the middle and lower part of the cylindrical side wall 17 is provided with a water outlet pipe 8, the lower edge of the cylindrical side wall 17 is provided with a flange 9, and the water collecting cap 5 and the swirl tube 1 are connected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com