Product cooling apparatuses

A product, cooler technology, applied in the field of pet food, can solve problems such as limiting cooling efficiency, reducing cooling process efficiency, sanitation problems, etc., and achieves the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention generally relates to pet food technology. More specifically, the present invention relates to engineered coolers or cooler apparatus for cooling pet food products and methods of use thereof. The pet food product can be, for example, any suitable pet food product that requires cooling or temperature regulation, such as extruded pet food, coated pet food, pellets, kibble, and the like.

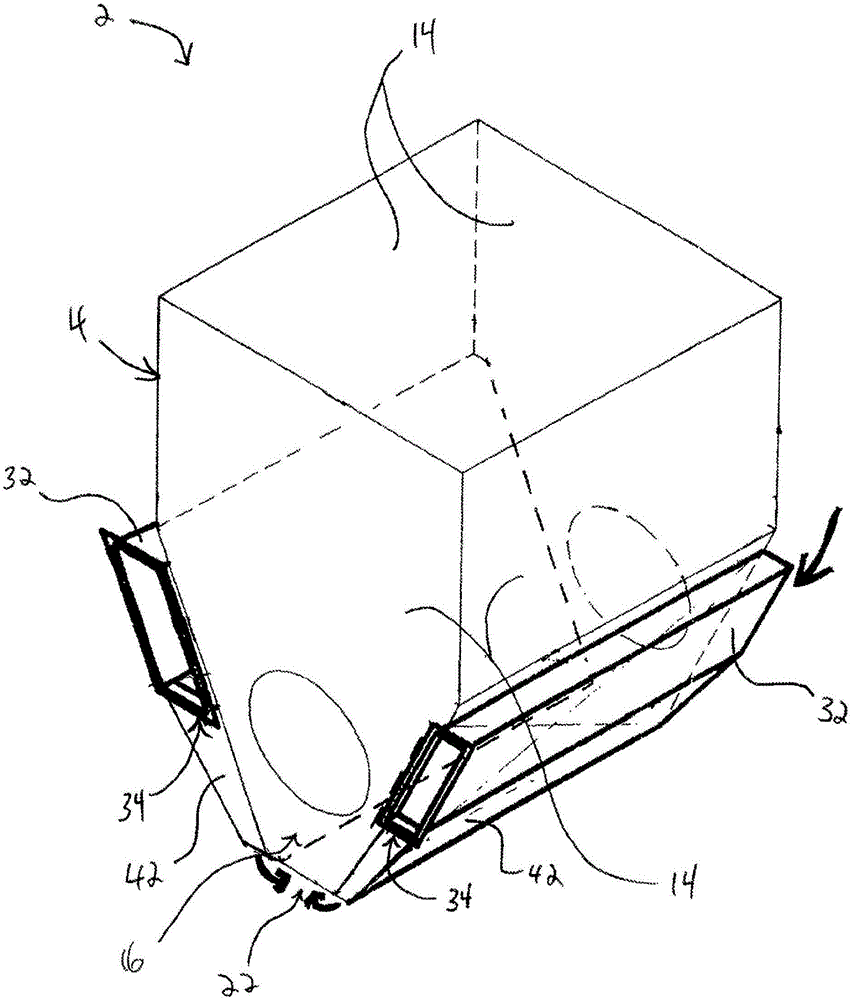

[0032] exist figure 1 In the illustrated embodiment, cooler 2 includes a hopper, container or chamber 4 having a product inlet, a product outlet and an air outlet. The cooler also includes one or more air ducts having exhaust ports constructed and arranged to provide airflow into the product outlet.

[0033] exist Figure 1-2 In the illustrated embodiment, the cooler 2 includes a chamber 4 having a plurality of walls 14 . The lower part 16 of the wall 14 forms a product outlet 22 . The product inlet 24 is in the chamber 4 and the air outlet 26 is also in the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com