Plug shell assembly and sub board plug

A technology for plug housings and assemblies, applied in electrical components, parts of connecting devices, coupling devices, etc., can solve the problems of easy tilting, affecting connector docking, adverse elastic push rod rebound, etc. Synchronization, ensuring resilience and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be further described below in conjunction with the drawings.

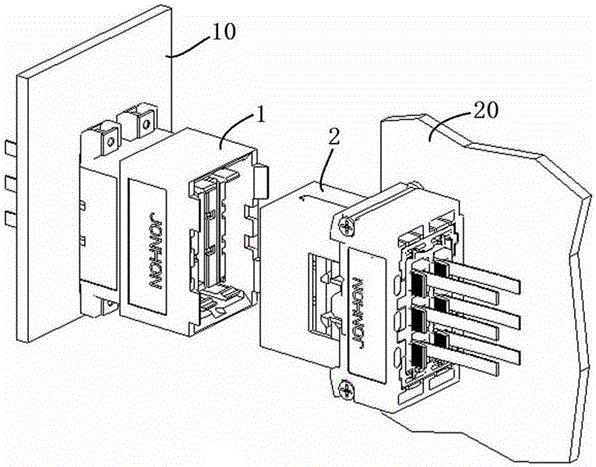

[0032] Specific embodiments of the plug connector of the present invention, such as figure 1 As shown, the daughter board plug of the present invention is installed on the daughter board 20 when in use, and is used to plug and cooperate with the back board socket 1 installed on the back board 10 to realize the optical signal transmission between the back board and the daughter board. Of course, in other embodiments, the daughter board plug may also be a conductive plug, which is used to realize the transfer and transmission of electrical signals.

[0033] For clarity of expression, the forward and backward directions in the present invention refer to the plugging direction of the plug, and to be precise, the forward direction is the direction in which the plug faces the socket.

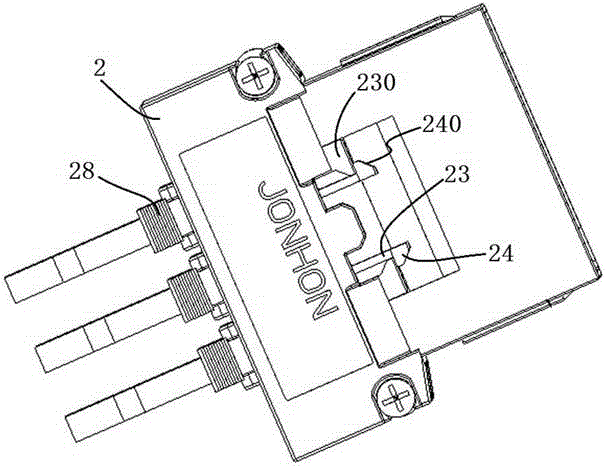

[0034] The daughter board plug 2 of the present invention includes a plug housing assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com