Multi-point supporting weighing mechanism

A weighing mechanism and multi-point support technology, applied in the direction of automatic feeding/discharging weighing equipment, weighing, measuring devices, etc. The effect of high precision, good working stability and accurate detection signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

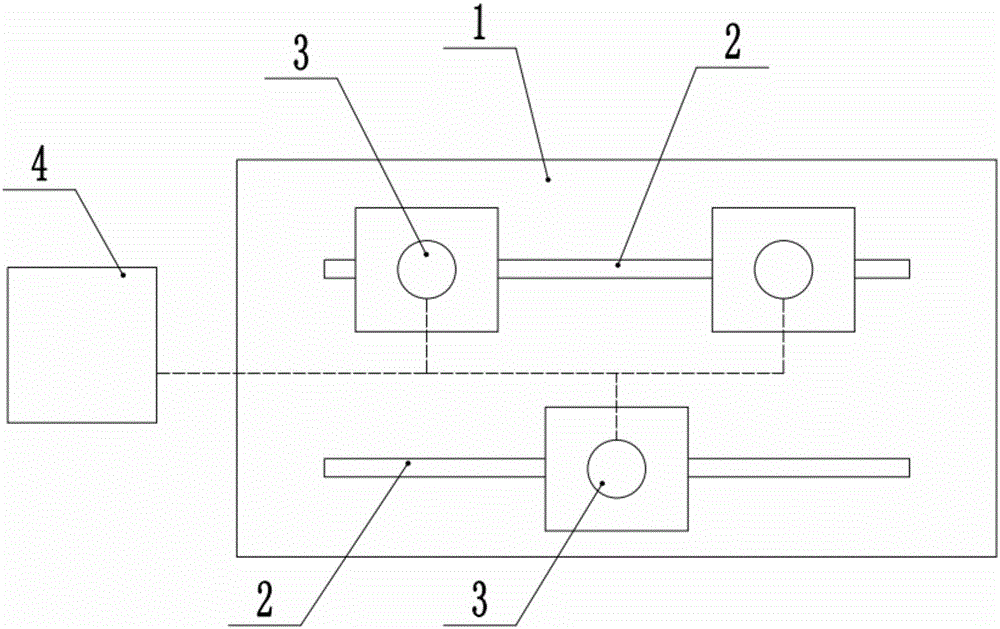

[0011] like figure 1 As shown, the multi-point supporting weighing mechanism of this embodiment includes a weighing support plate 1, two parallel guide rails 2 are arranged below the weighing support plate 1, and two weighing scales are installed at intervals on one guide rail 2. A load cell 3 is installed on the other guide rail 2; the three load cells 3 are all connected to the controller 4, and the controller 4 outputs the signals of the three load cells 3 after centralized processing.

[0012] All three load cells 3 can slide on the guide rail 2 to realize the fine adjustment of the weighing, the weighing is more accurate and the adjustment is convenient.

[0013] The above examples are preferred implementations of the present invention, and are only used to illustrate the present invention conveniently, and are not intended to limit th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com