Double-end-face fluid dynamic and static pressure mechanical seal for sodium cooling fast reactor nuclear main pump

A sodium-cooled fast reactor and mechanical seal technology, which is applied to liquid fuel engines, components of pumping devices for elastic fluids, mechanical equipment, etc. Guaranteed stability and durability, avoids abrasive wear, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

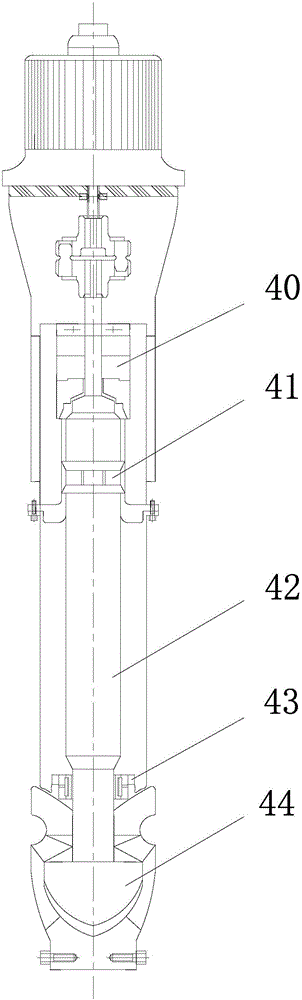

[0080] Example 1: A double-end fluid dynamic and static pressure mechanical seal for a sodium-cooled fast reactor nuclear main pump with axial and radial combined channels on the moving ring

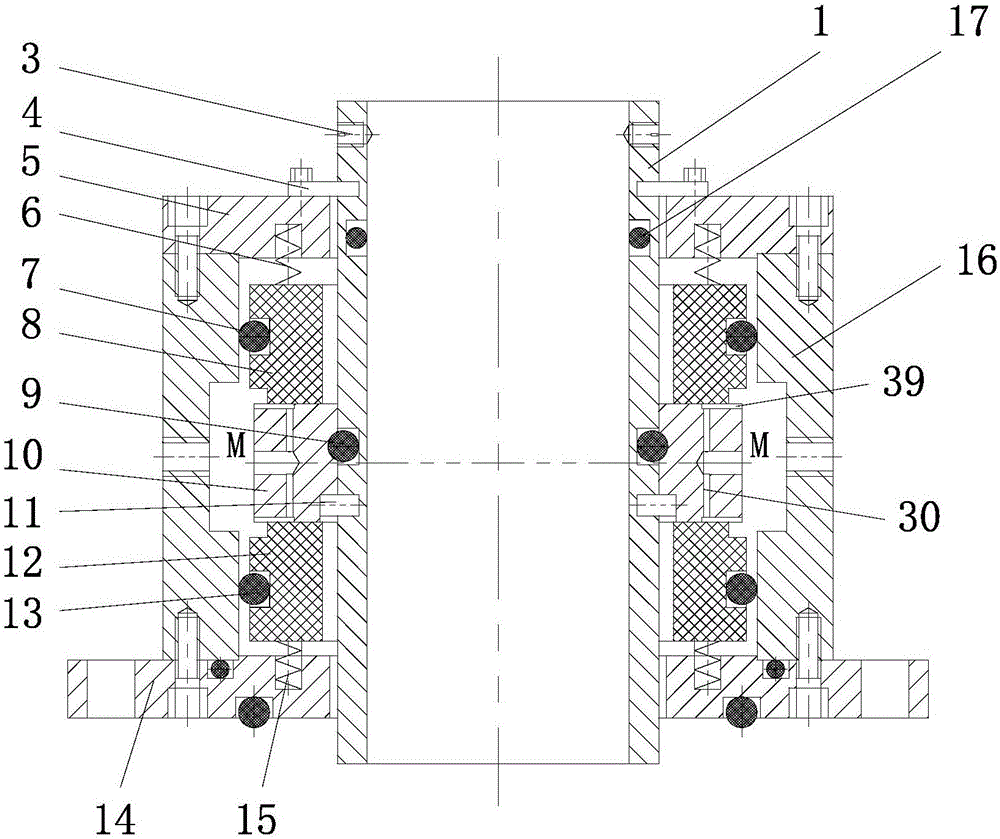

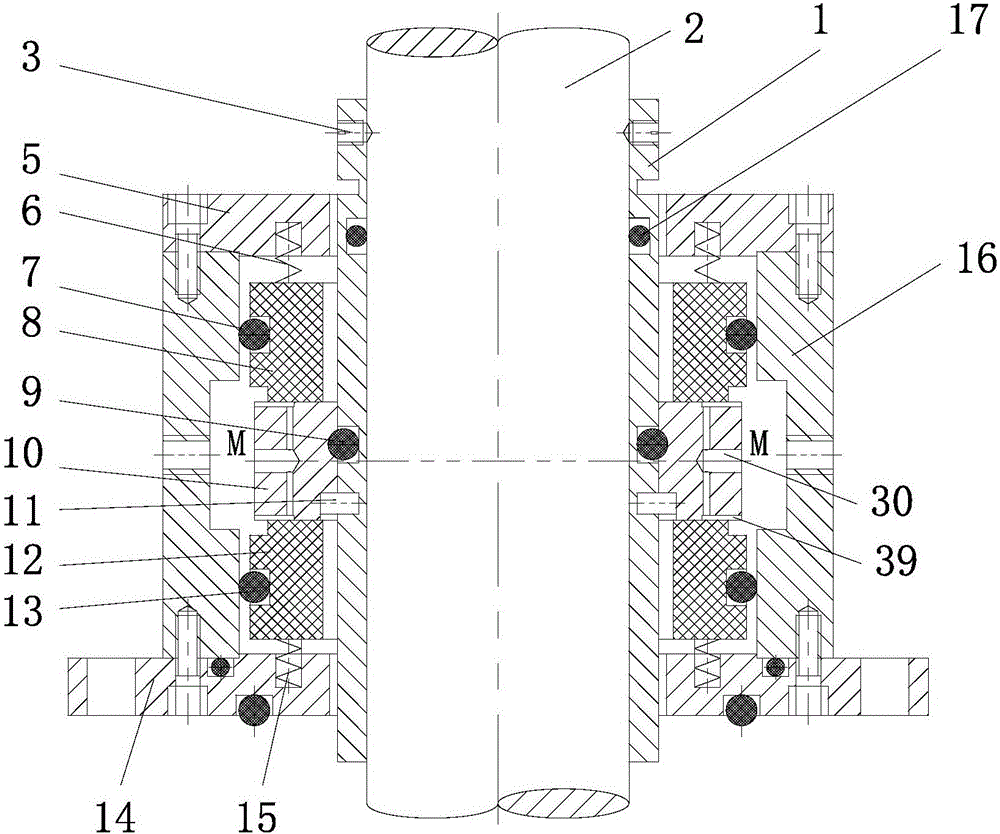

[0081] see figure 2 , 3 , 6, the inlets 31 of the back-curved fluid grooves 39 located at the upper and lower ends of the moving ring are all communicated with the outer sealing space through the axial and radial combination channels 30 opened on the moving ring 10 . When the moving ring rotates, the blocking fluid in the outer sealing space, such as argon, flows into the back-curved fluid groove 39 through the axial and radial combined holes 30 on the moving ring 10 under the action of pressure difference, forming a self-pump again and again. send loop.

Embodiment 2

[0082] Example 2: A double-end fluid dynamic and static pressure mechanical seal for a sodium-cooled fast reactor nuclear main pump with circular grooves on the moving ring and axial and radial combined channels on the static ring

[0083] see Figure 4 , 5 , 7 and 8, the inlet 31 of the back-curved fluid groove 39 on the moving ring communicates with the circular ring groove 36 arranged in the middle of the sealing surface of the moving ring 10 . One end of the axial-radial combination hole 30 opened on the static ring communicates with the outer sealing space, and the other end is opposite to the circular ring groove 36 in the axial direction.

[0084] When the moving ring rotates, the blocking fluid in the outer sealing space, such as argon, flows into the back-curved fluid type through the axial and radial combination channels 30 on the static ring and the circular ring groove 36 on the moving ring under the action of pressure difference. In the tank 39, a self-pumping c...

Embodiment 3

[0085] Example 3: A double-end fluid dynamic and static pressure mechanical seal for a sodium-cooled fast reactor nuclear main pump with circular grooves and axial and radial combined channels on the static ring

[0086] see Figure 9 , 10 shown (refer to Figure 4 , 5 ), the inlet 31 of the back-curved fluid-type groove 39 on the moving ring communicates with the circular groove 36 opened in the middle of the sealing surface of the static ring, and the circular groove 36 is combined through the axial radial direction opened on the static ring The tunnel 30 communicates with the outer sealed space. When the moving ring rotates, the blocking fluid in the outer sealing space, such as argon, flows into the back-curved fluid type through the axial and radial combination channels 30 on the static ring and the circular ring groove 36 on the static ring under the action of pressure difference. In the tank 39, a self-pumping cycle is formed time after time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com