Pre-separation effect test method for oil-gas separator

A technology of oil and gas separator and test method, which is applied in the directions of machines/engines, pumping devices for elastic fluids, rotary piston type/oscillating piston type pump components, etc., and can solve the problem of large oil removal pressure of filters, Shorten service life, increase maintenance cost and other problems, achieve the effect of reducing degreasing pressure, reducing maintenance cost and improving quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

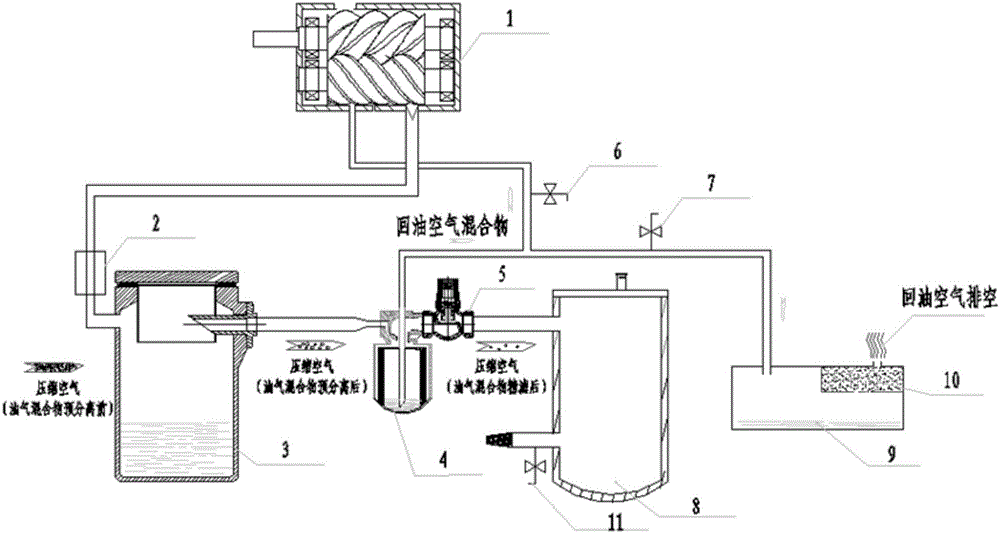

[0024] like figure 1 As shown, the hardware used in the pre-separation effect test method of the oil-gas separator includes: screw compressor 1, oil-gas separator 3, oil separation core 4, pressure stabilizing air cylinder 8, oil collection box 9, and the compressed air output port of screw compressor 1 The flow rate adjustment device 2 is connected to the inlet of the oil-gas separator 3, the compressed air outlet of the oil-gas separator 3 is connected to the pressure-stabilizing air cylinder 8 through the oil separation core 4 and the minimum pressure valve 5, and the bottom of the oil-gas separator passes through the primary oil return pipeline (not shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com