Friction pendulum isolation device

A pendulum and shock-isolation technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of low reliability of damping energy-dissipating devices, large space occupation rate of damping energy-dissipating devices, and weak support structure stability. , to achieve the effect of preventing bridge beam drop, simple mechanism of shock absorption and isolation, and low space occupancy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

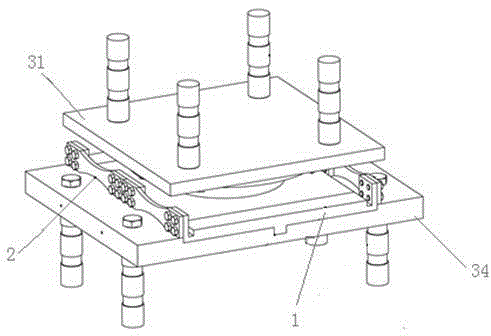

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as Figure 1 to Figure 3 As shown, the friction pendulum type vibration isolation device includes a friction pendulum type vibration isolation support and a brake energy dissipation assembly. 32. The lower seat plate 33 and the bottom plate 34, the double spherical middle seat plate 32 and the upper seat plate 31 and the lower seat plate 33 respectively form a sliding spherical friction pair and a rotating spherical friction pair, and a plane is formed between the lower seat plate 33 and the bottom plate 34 Sliding friction pair, the center of the top surface of the bottom plate 34 is provided with a chute 35 arranged along the front and rear direction of the friction pendulum type shock-isolation bearing, and the bottom surface of the lower seat plate 33 has a guide rail that slides and fits with the chute 35;

[0024]The brake energy dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com