Front mounting assembly used for power assembly

A powertrain and front suspension technology, applied in the field of vehicles, can solve the problems that affect the vibration isolation performance of the suspension system, cannot be realized according to the design, and the suspension rubber is twisted, so as to achieve excellent NVH performance, reduce vibration transmission paths, Remove the effect of overconstraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

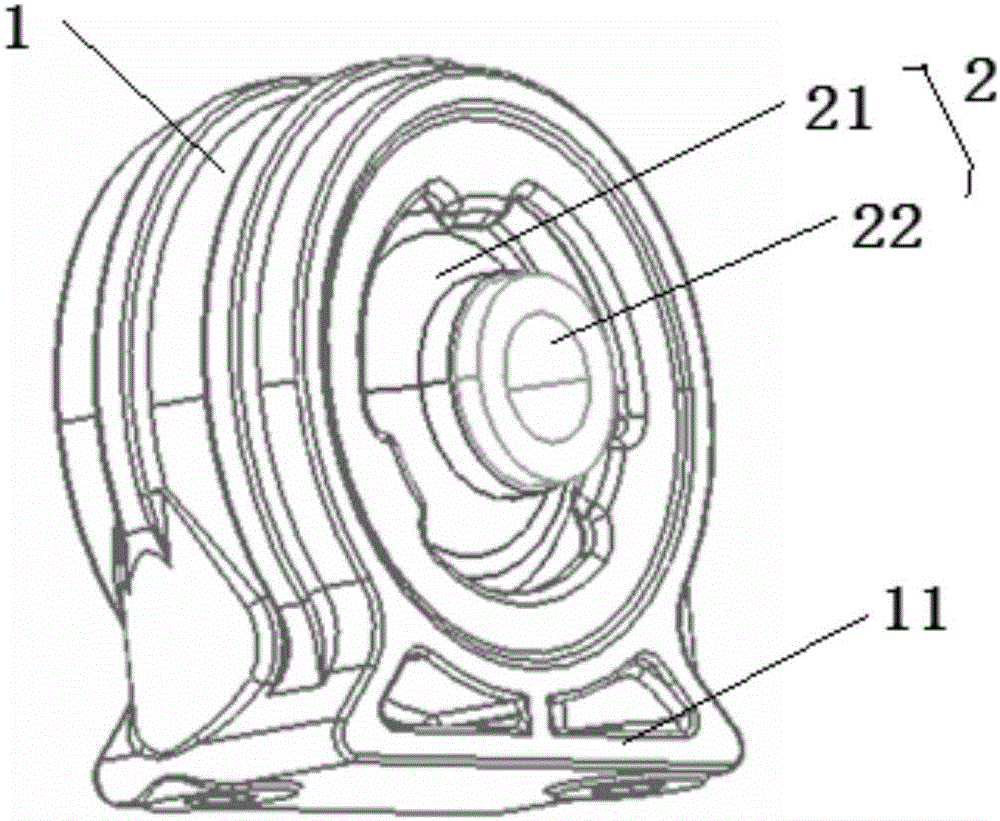

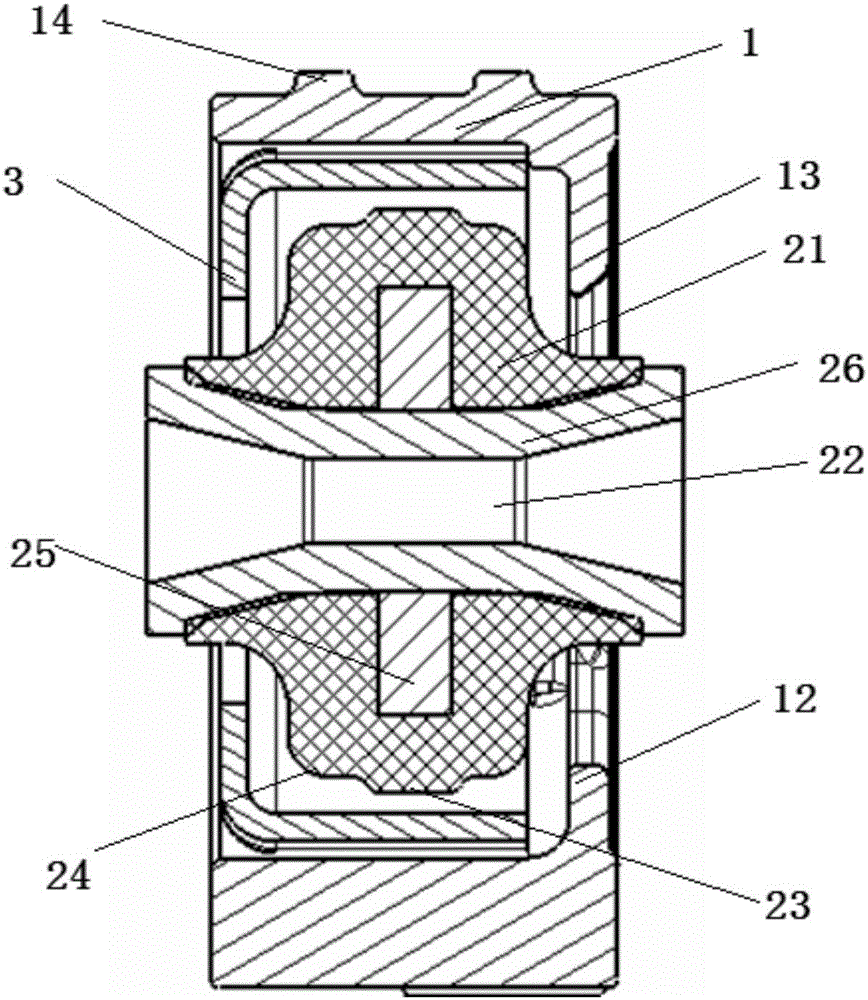

[0038] figure 1 It is a structural schematic diagram of a front suspension assembly for a powertrain according to an embodiment of the present invention. Such as figure 1 As shown, the front suspension assembly for the powertrain can be arranged on the front side of the powertrain (not shown in the figure) through the connecting piece (not shown in the figure), including the main body bracket 1, the inner tube assembly 2 and riveting support 3. The main body support 1 can be fixedly connected with the vehicle frame, and the main body support 1 is hollow and has an accommodating space inside. The inner tube assembly 2 includes an inner tube 22 and a main rubber spring 21, and the inner tube 22 and the main rubber spring 21 are vulcanized into one structure. The inner tube assembly 2 is movably placed in the accommodating space. The riveting bracket 3 and the main body bracket 1 jointly define the position of the inner tube assembly 2 in the accommodating space, so that thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com