Secondary forming processing method of plastic product

A technology for plastic products and secondary molding, applied in the field of plastic molding, can solve problems such as distortion, unevenness, warpage, etc., and achieve the effect of improving warpage, deformation defect improvement, and deformation defect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] figure 1 It is a flow chart of a plastic product secondary molding treatment method provided in the embodiment of the present application, and the method includes:

[0029] Step 101: heating the obtained once-molded plastic product;

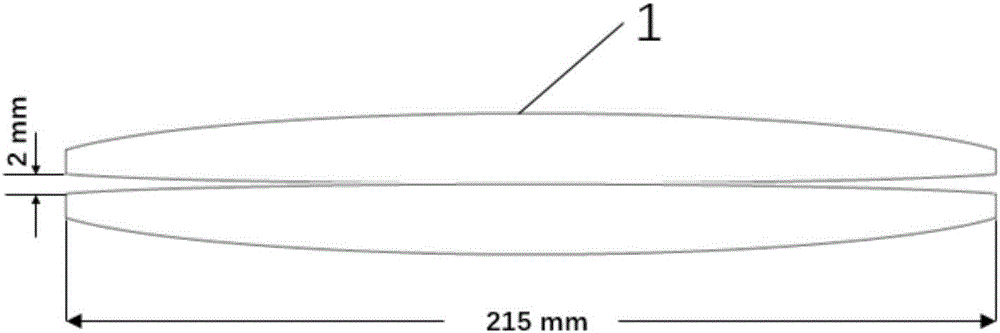

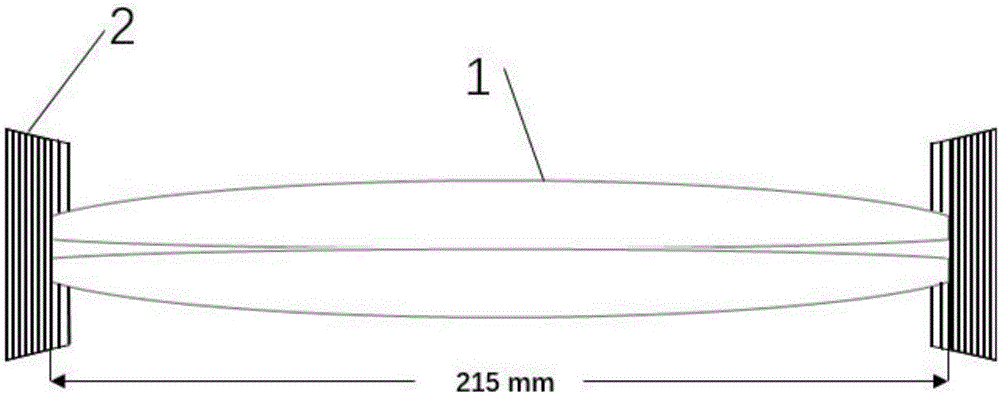

[0030] The embodiment of the present application provides a secondary molding processing method for plastic products. Before performing secondary molding on the plastic product, firstly obtain a plastic product of primary molding, which can be obtained by injection molding or blow molding in the prior art. of plastic products. Such as figure 2 Shown is a schematic diagram of a one-time molded plastic product provided by the embodiment of the present application. The length of the one-time molded plastic product 1 is 215 mm, and the gap between the upper and lower buckle covers is 2 mm.

[0031] The purpose of heating the obtained once-molded plastic product 1 is to soften the once-molded plastic product 1 so that it can be molded again...

Embodiment 2

[0045] Figure 5 Another flow chart of a plastic product secondary molding processing method provided in the embodiment of the present application, the method includes:

[0046] Step 201: Obtain a plastic product molded at one time;

[0047] In yet another secondary molding treatment method for plastic products provided in the embodiment of the present application, before performing secondary molding on the plastic product, firstly obtain a plastic product that is once molded, which can be obtained by injection molding or blow molding in the prior art A molded plastic product.

[0048] Step 202: covering the surface of the once-molded plastic product with a heat-shrinkable film;

[0049] Specifically, covering the heat-shrinkable film can fix, cover and protect the plastic product.

[0050] Step 203: heating the once-molded plastic product covered with the heat-shrinkable film;

[0051] Specifically, heating the once-molded plastic product can soften the once-molded plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com