Double-head large-torque screwdriver

A high-torque, screwdriver technology, used in screwdrivers, manufacturing tools, etc., can solve the problem of inconvenient replacement of screwdriver heads, and achieve the effects of simple structure, easy operation, and easy access to parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

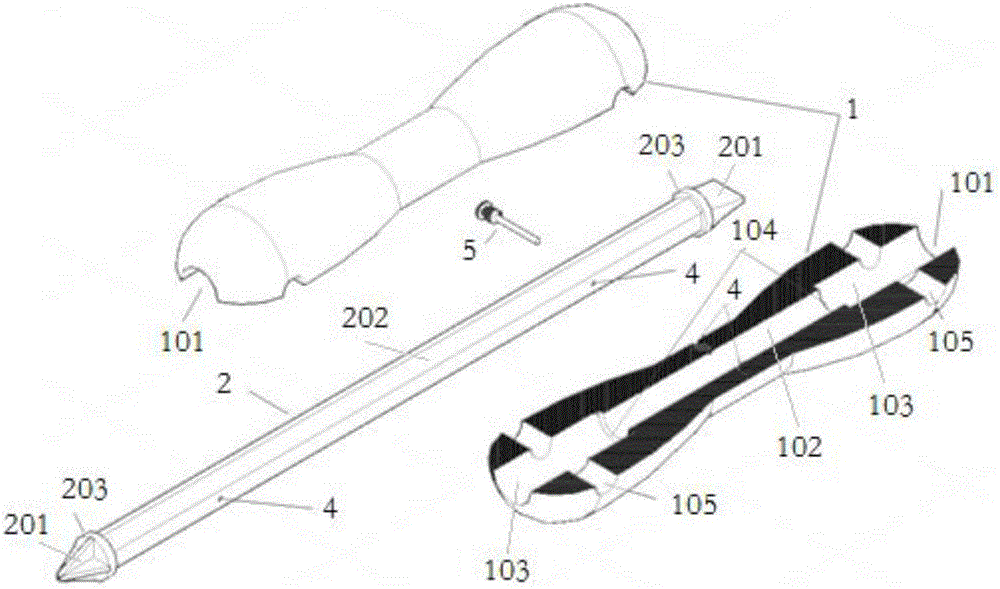

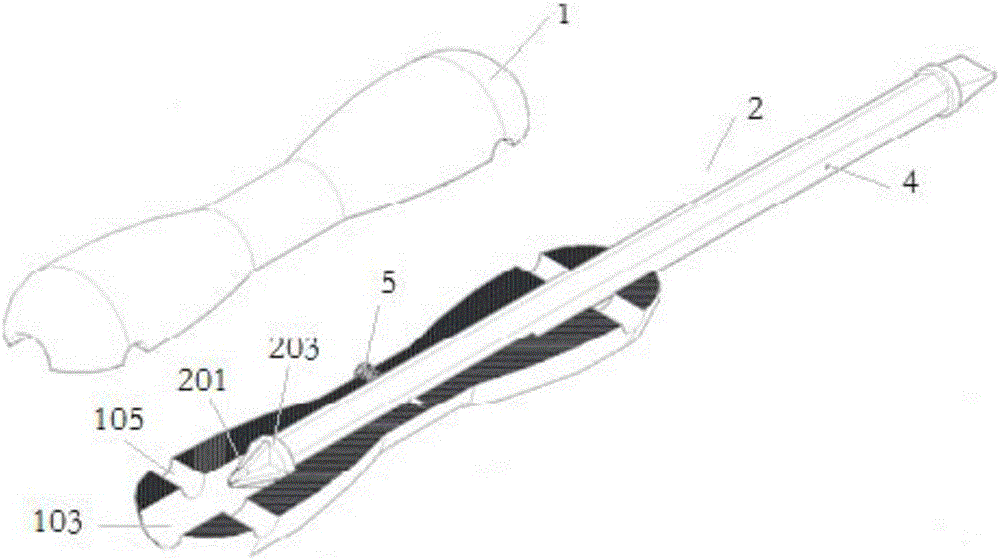

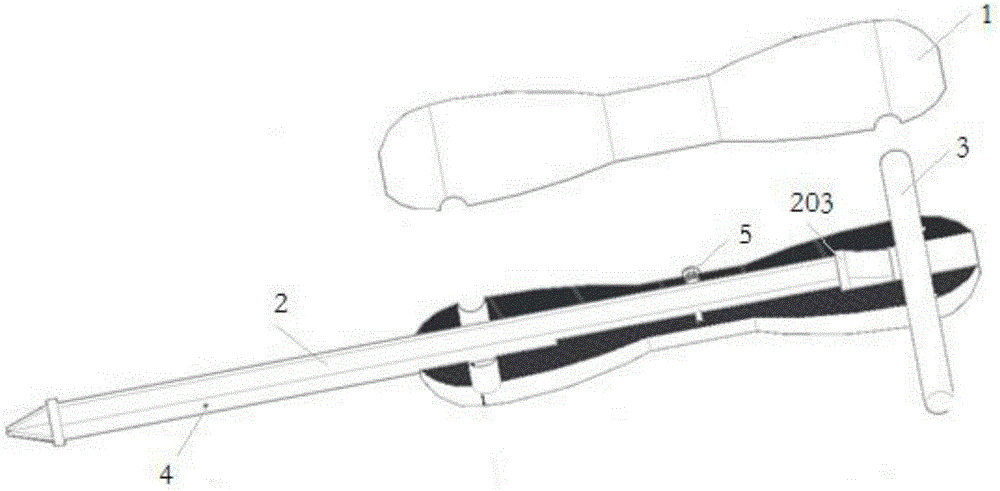

[0022] refer to Figure 1-Figure 3 , the double-headed high-torque screwdriver of this preferred embodiment includes a handle 1 and a handle 2; wherein, there is a first concave channel 101 arranged in the axial direction of the handle in the handle, and the first concave channel is divided into a middle section 102 and a middle section 102. The two end sections 103, the middle section and the two end sections all have substantially the same circular cross-section, and the diameters of the two end sections are larger than the middle section diameter. At this time, a stepped hole is formed at the transition between the two end sections and the middle section, and the stepped hole It acts as the limit hole 104 of the cutter bar. Both ends of the handle also have a second recessed channel 105 arranged perpendicular to the axial direction of the handle, and the moment rod 3 can be arranged in the second recessed channel. The cutter bar 2 is accommodated in the first concave chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com