The Deep and Narrow Groove Precise Machining Method of Flame Tube Thin-walled Parts

A thin-walled part, precision machining technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

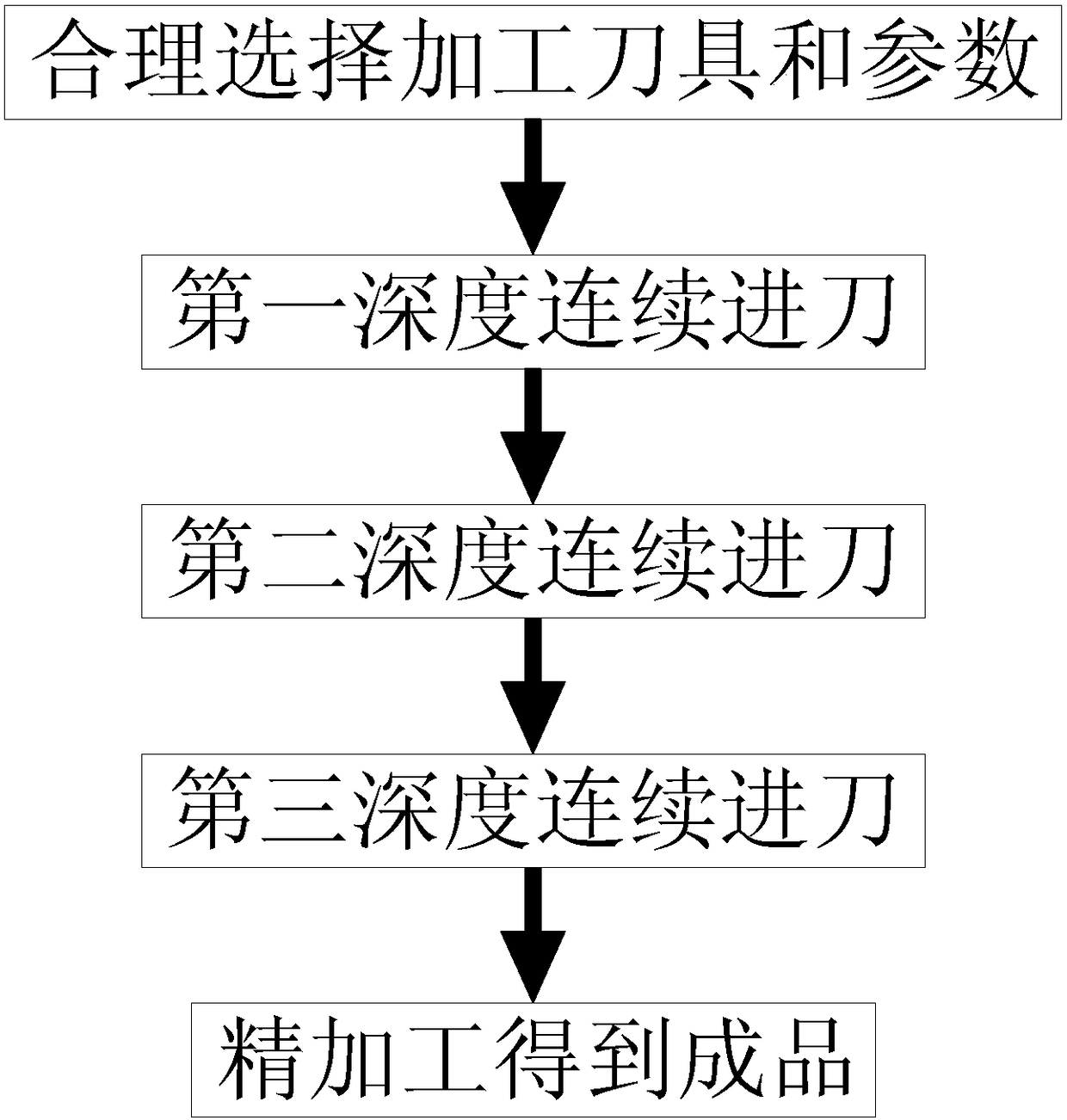

[0047] Considering that the material of the part is GH3044, which is a nickel-based solid solution alloy, the hardness HBd≥3.6, and the machining performance is poor, the appropriate cutting amount (cutting speed, feed rate, back cutting amount) is determined based on the tool model and material characteristics. )scope;

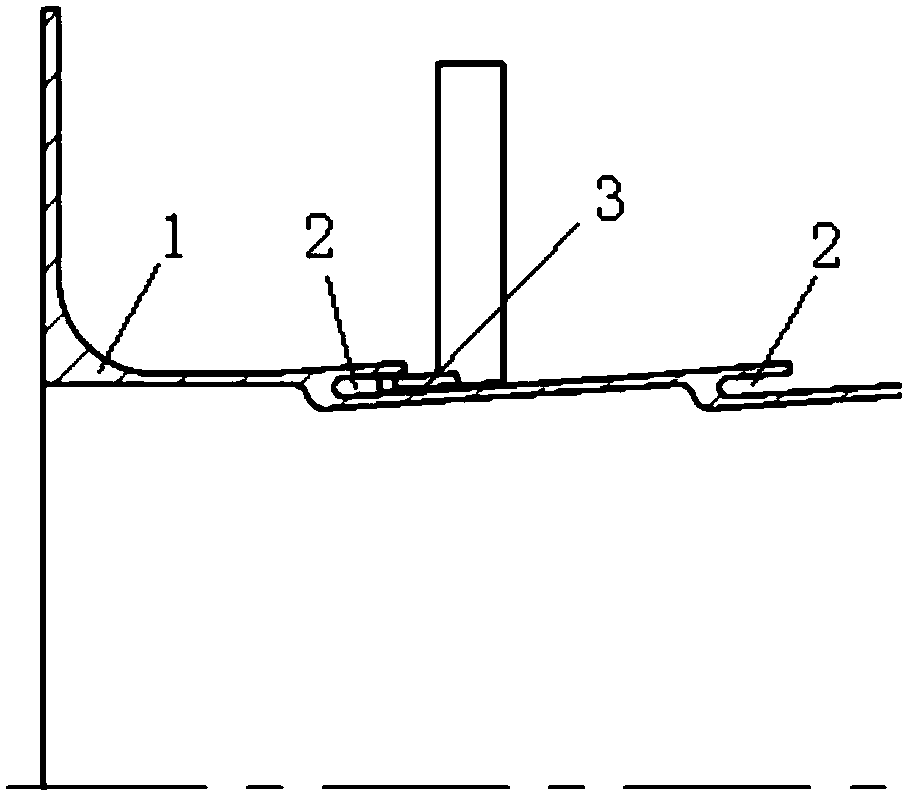

[0048] Considering that the slot width of the part is required to be 1.5 (+0.1, 0) mm, use a slot cutter with a width of 1.5 mm and a tool tip arc R0.1 for rough machining, and use a slot with a width of 1.5 mm and a tool tip arc R0.75 Knife for finishing.

[0049] 1. Within the allowable feed range, use the maximum feed speed to cut into the groove depth of 1.5mm. The iron chips formed at this time are thick and hard, which can realize automatic chip removal and ensure a certain processing efficiency;

[0050] 2. From the groove depth of 1.5mm to the position of 3 / 4 groove depth, use medium feed for processing, and the iron filings formed at this time are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com