A low-temperature methane combustion catalyst for ebullating bed reactors and its preparation method and application

A fluidized bed reactor and low-temperature combustion technology, which is applied in the fields of environmental protection and chemical engineering, and achieves the effects of high load capacity, high combustion efficiency, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the methane low-temperature combustion catalyst provided in this embodiment comprises the following steps:

[0034] Aluminum hydroxide with a particle size of 20-200 μm is roasted at 750°C for 6 hours and then used as a microspherical carrier; lanthanum nitrate, calcium nitrate, cobalt nitrate, manganese nitrate and citric acid are prepared as the precursor of the perovskite active component Body solution; wherein the metal ion lanthanum: calcium: cobalt: the molar ratio of manganese is 9:1:5:5, and the ratio of citric acid to the total molar weight of metal ions (lanthanum, calcium, cobalt, manganese) is 1:1 , the perovskite active component precursor solution was loaded on the microspherical carrier with a loading rate of 5%, dried at 60°C for 5h, and then calcined at 700°C for 4.5h to obtain catalyst A.

Embodiment 2

[0036] The preparation method of the methane low-temperature combustion catalyst provided in this embodiment comprises the following steps:

[0037] Aluminum hydroxide with a particle size of 20-200 μm is roasted at 1100°C for 1.5 hours and then used as a microspherical carrier; lanthanum nitrate, strontium nitrate, cobalt nitrate, manganese nitrate and citric acid are used to make perovskite active components Precursor solution; wherein the molar ratio of metal ions lanthanum: strontium: cobalt: manganese is 7:3:5:5, and the ratio of citric acid to the total molar weight of metal ions (lanthanum, strontium, cobalt, manganese) is 0.5 : 1, loading the perovskite active component precursor solution on the microspherical carrier with a loading rate of 30%, drying at 60°C for 12h, and roasting at 900°C for 2h to obtain catalyst B.

Embodiment 3

[0039] The preparation method of the methane low-temperature combustion catalyst provided in this embodiment comprises the following steps:

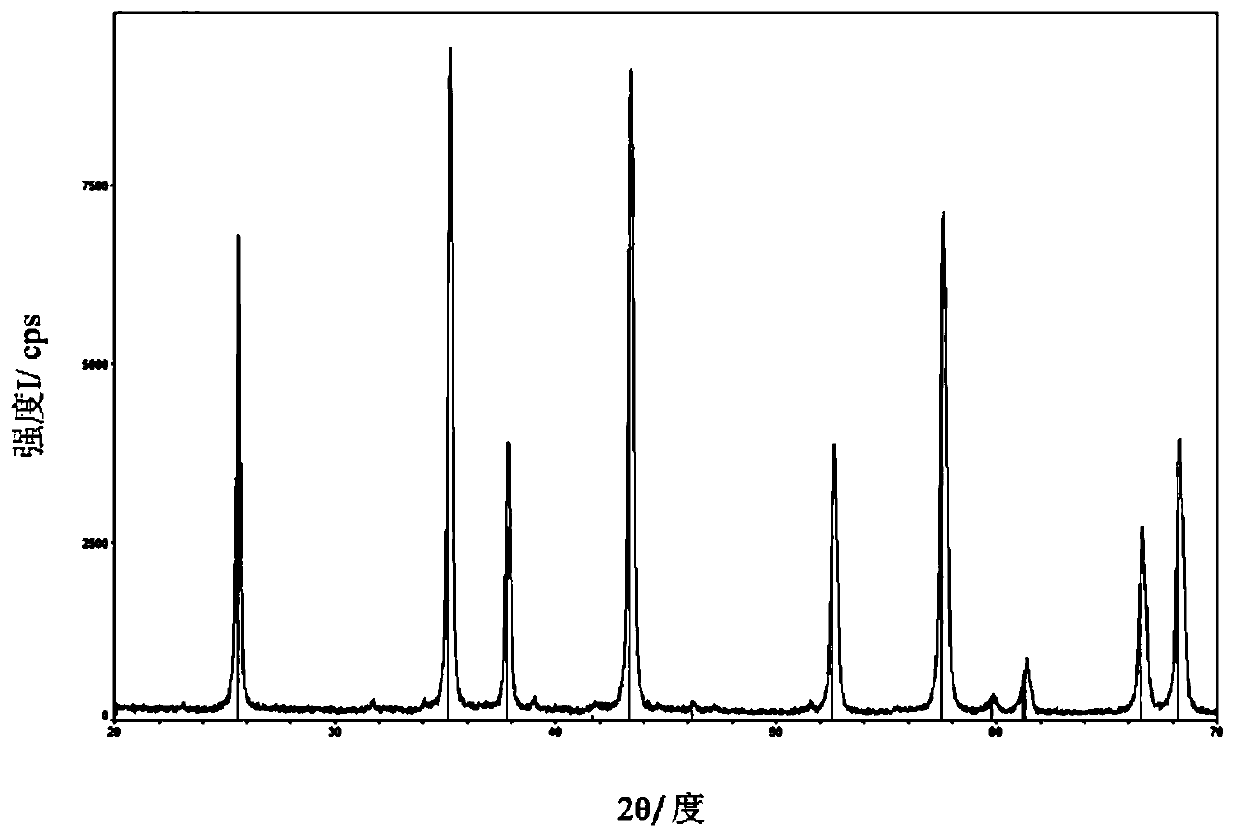

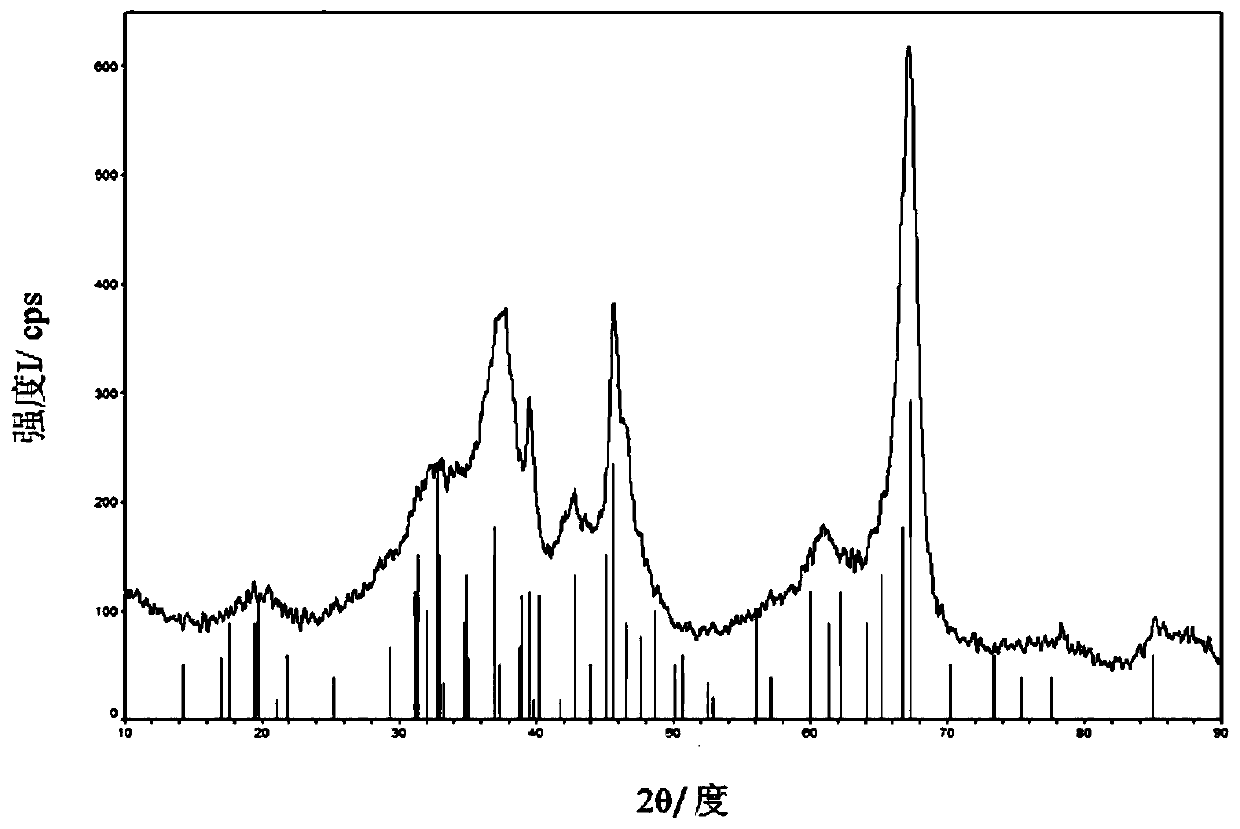

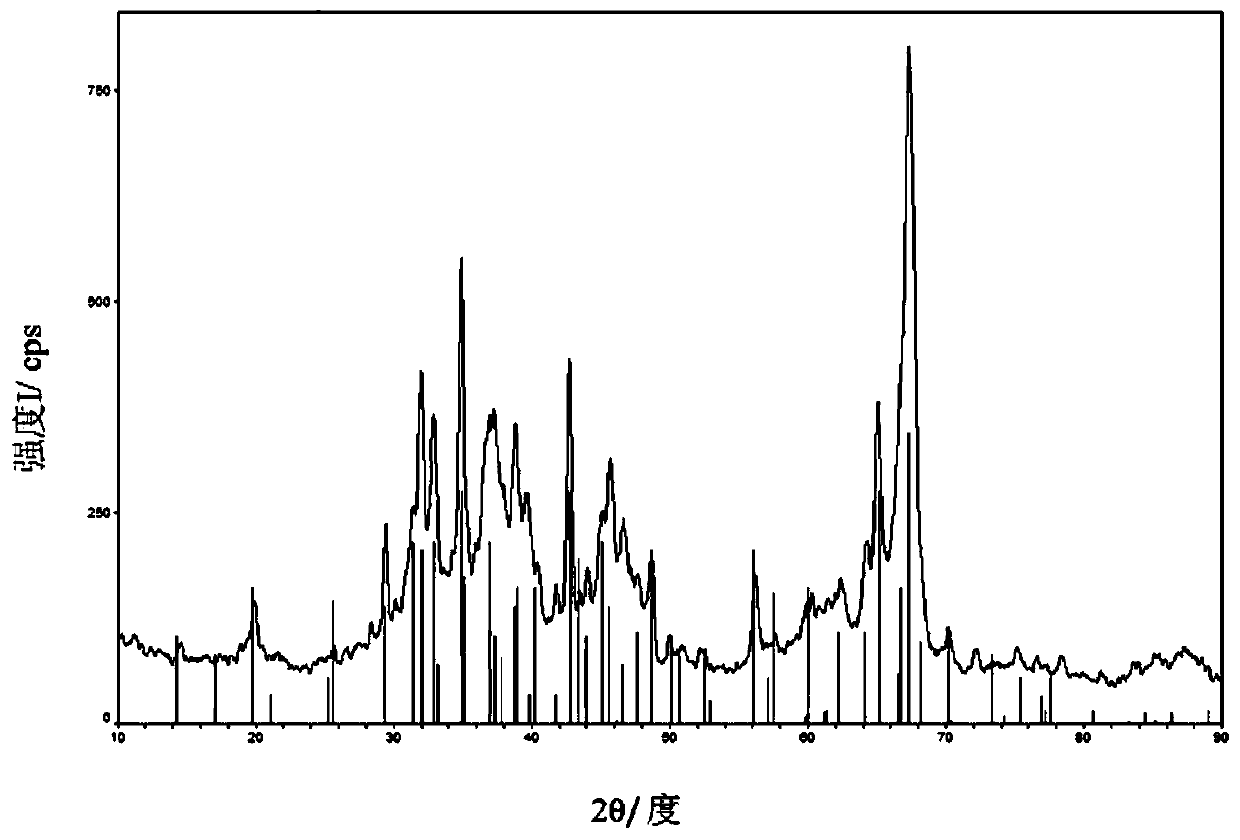

[0040] κ-Al obtained by calcining aluminum hydroxide with a particle size of 20-200 μm at 1200 ° C for 0.5 h 2 o 3 and α-Al 2 o 3 Alumina of mixed crystal phase is used as microsphere support (such as figure 1 shown); Lanthanum nitrate, barium nitrate, copper nitrate, manganese nitrate and lactic acid are made into the precursor solution of perovskite type active component; Wherein metal ion lanthanum: barium: copper: the molar ratio of manganese is 5: 5:1:9, the total molar ratio of lactic acid to metal ions (lanthanum, strontium, cobalt, manganese) is 2:1, the perovskite active component precursor solution is loaded on the microspherical carrier, and the loading rate is 2%, dried at 120°C for 1.0h, and then calcined at 1000°C for 1.0h to obtain catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com