A kind of preparation method and application of heu type molecular sieve

A technology of molecular sieve and molecular weight, which is applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems that the safety factor cannot meet the production and transportation, and the safety factor is reduced, and achieves excellent separation ability and large dynamic adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

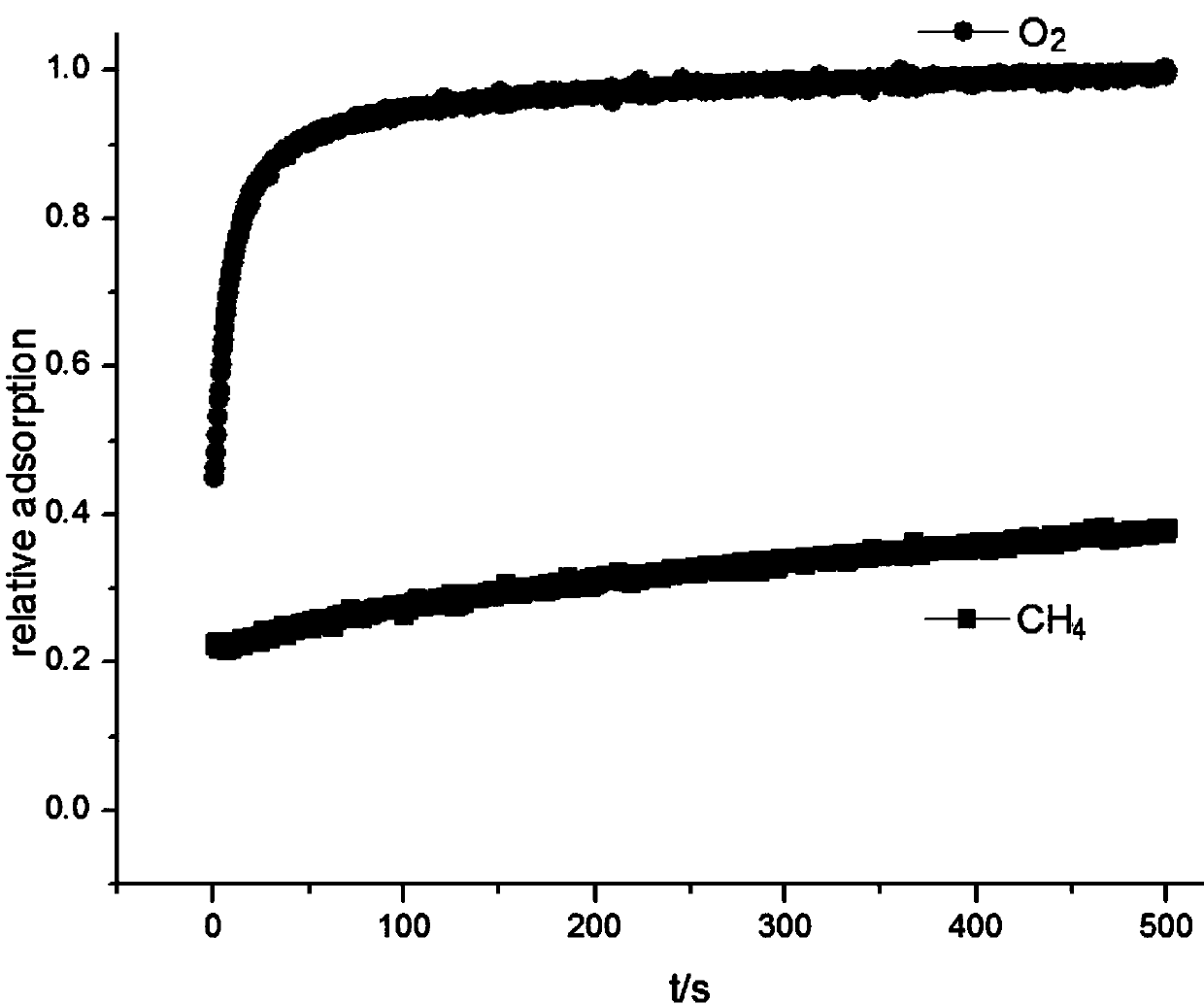

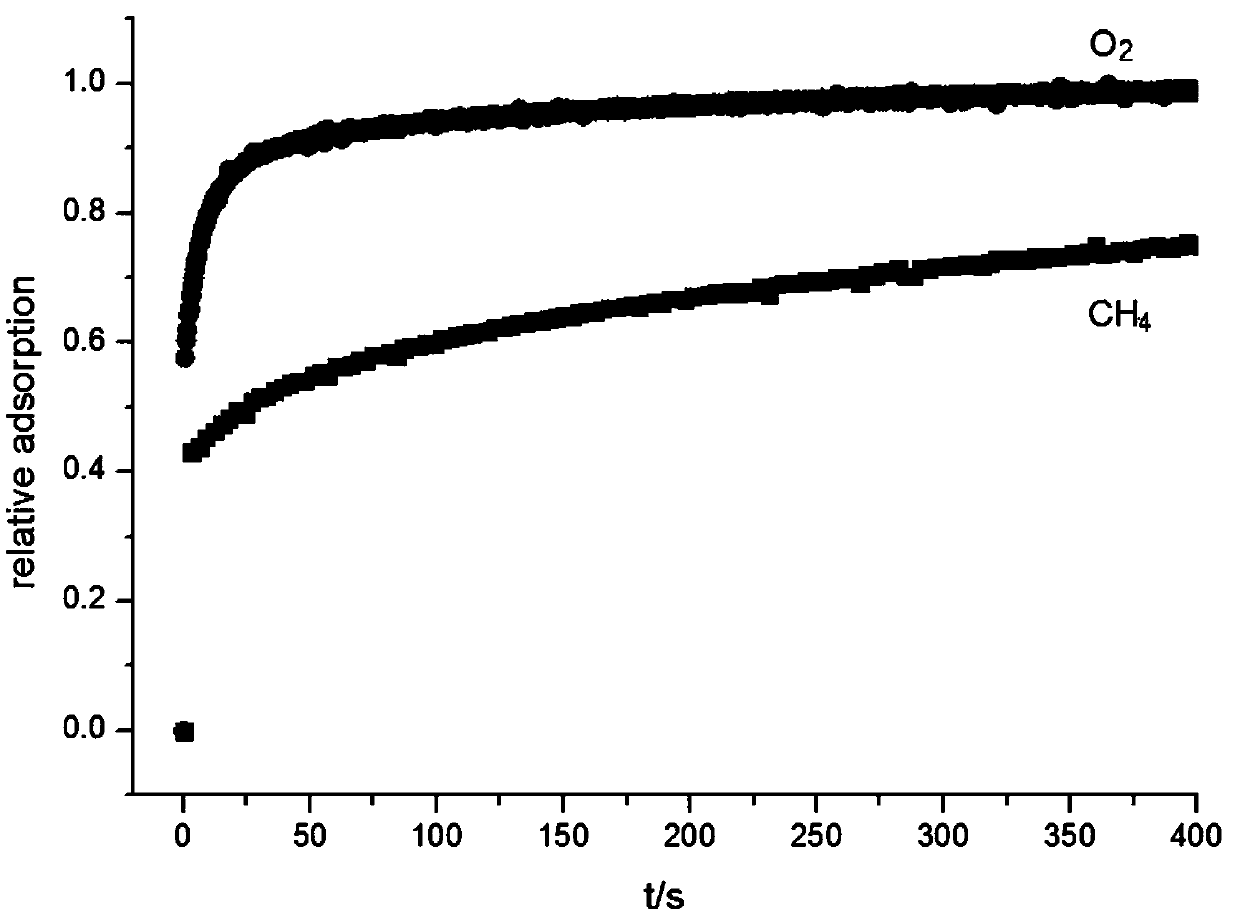

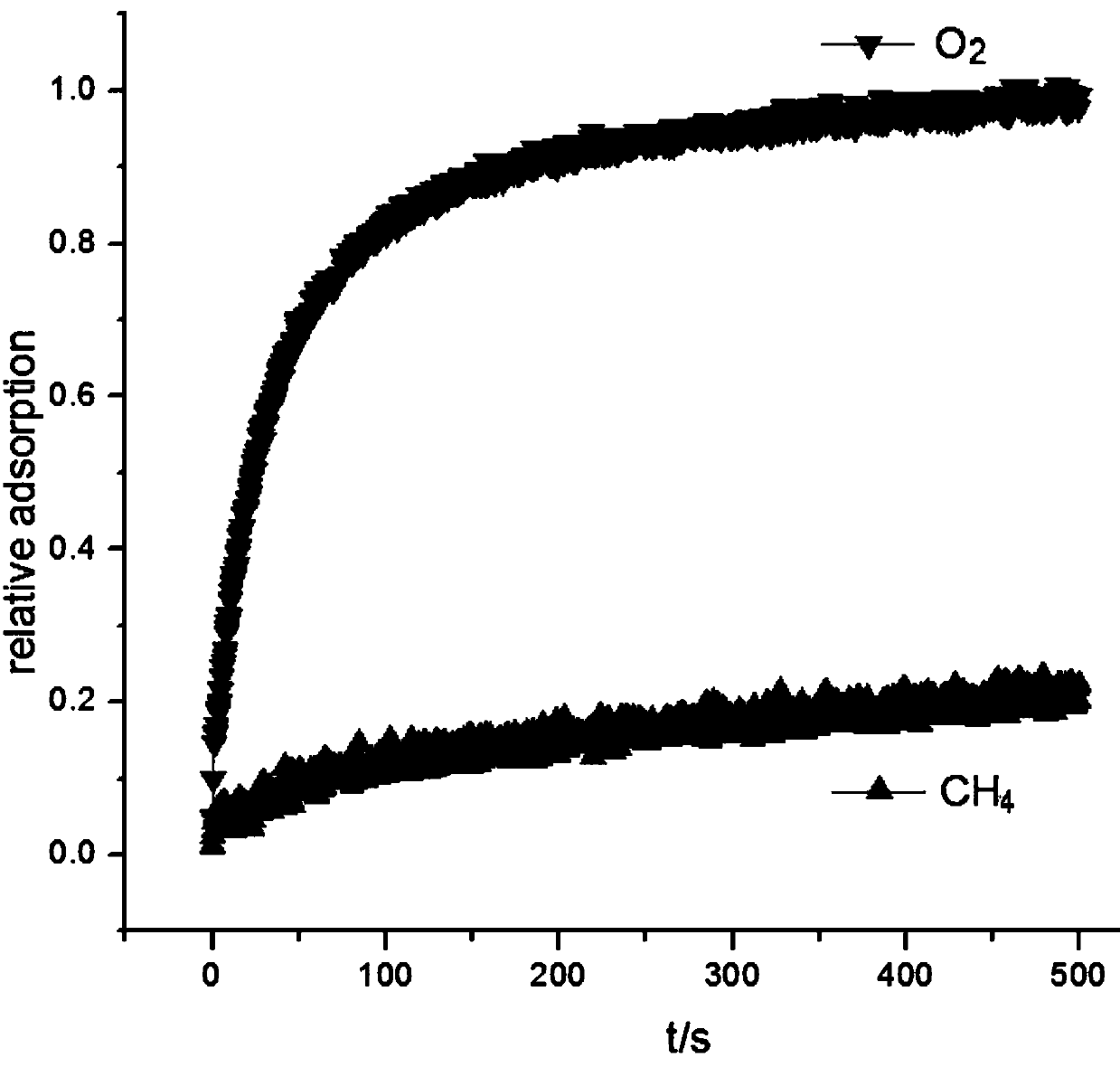

Image

Examples

Embodiment 1

[0035] (1) Preparation of K-HEU: 50g of artificially synthesized HEU raw powder (Al 2 o 3 8.2SiO2 2 0.45K 2 O 0.38Na 2 O 0.11CaO 0.06MgO 3H 2O) Mix with 15g of potassium chloride in a beaker, add 500ml of distilled water, heat to 80°C while stirring, exchange for 1h, filter and wash, bake at 80°C for more than 12h to obtain K-HEU, K 2 The molar ratio of O in the ion is 99.8%.

[0036] (2) Preparation of K / Na-HEU: Mix 40g of K-HEU prepared in step (1) with 160g of sodium chloride in a beaker, add 800ml of distilled water, heat to 75°C while stirring, and exchange for 45min. Repeat the above steps for the second exchange of the filter cake obtained by filtering and washing. After filtering and washing, bake at 80°C for more than 12 hours to obtain K / Na-HEU, Na 2 The molar ratio of O in the ion is 81.4%, K 2 The molar proportion of O is 18.6%.

[0037] (3) Preparation of K / Na / Mg / Ca-HEU: Mix 15g of K / Na-HEU prepared in step (2) with 15g of magnesium chloride and 7g of calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| adsorption temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com