Liquid output equipment and liquid output control method

A technology for outputting equipment and liquids, which is applied in beverage preparation devices, kitchen utensils, household utensils, etc., and can solve problems such as complex flushing trajectories and inability to make

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

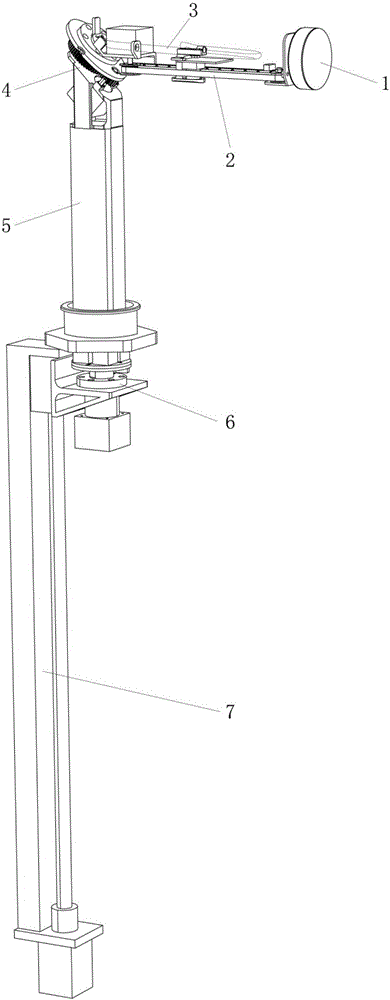

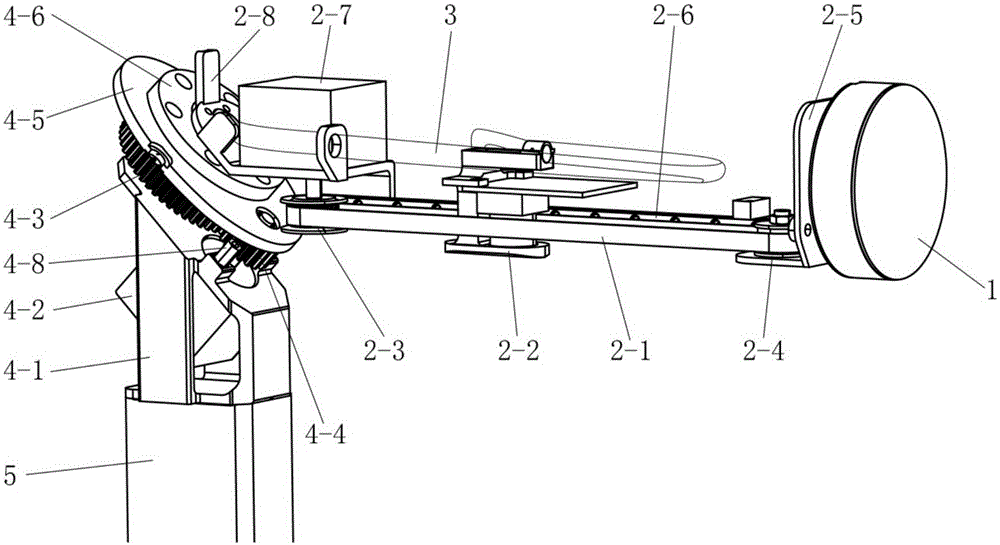

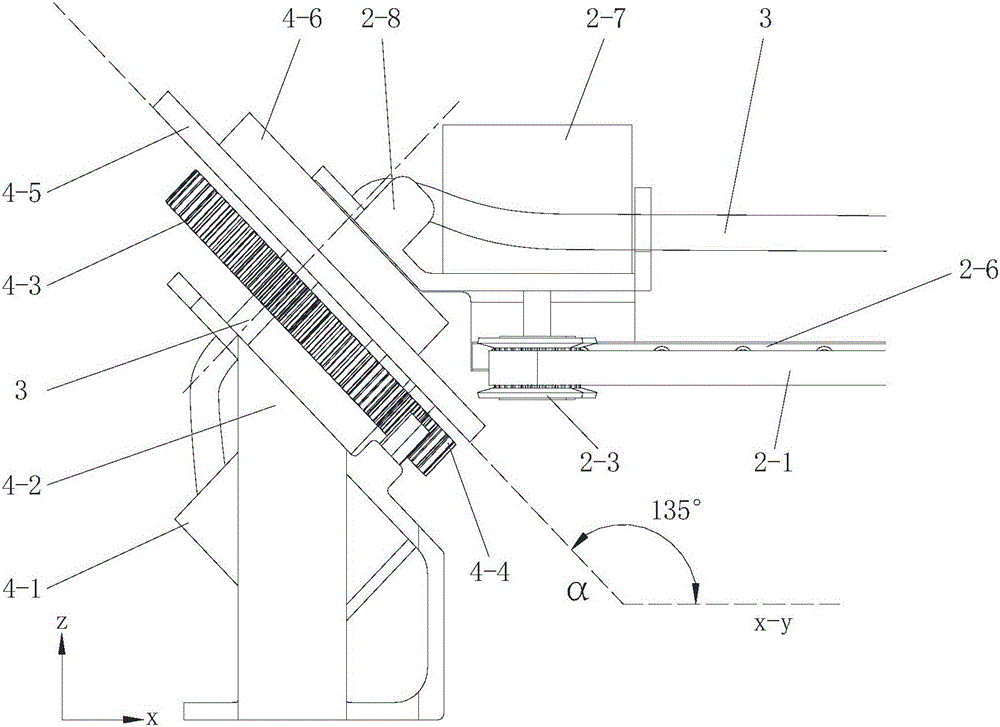

[0054] Such as figure 1 , figure 2 , image 3 Shown is Embodiment 1 of the present invention. In this embodiment, a liquid output device includes an upper body and a lower body. The upper body includes a first column 5 and a cantilever 2. The first column 5 and the cantilever 2 are jointed by angle adjustment. 4 connection combination; the first driving module and the water outlet module 2-2 are arranged on the cantilever 2, and the first driving module drives the water outlet module 2-2 to move along the length direction of the cantilever 2; the angle adjustment joint 4 is provided with a second Two driving modules, the second driving module drives the cantilever 2 to rotate, so that the cantilever 2 can be converted between horizontal and vertical positions; the lower body is provided with a third driving module 6, and the third driving module 6 passes through the first column 5 Supporting the upper body, the third driving module 6 drives the upper body to rotate around t...

Embodiment 2

[0078] Such as Figure 5 , Figure 6 Shown is Embodiment 2 of the present invention. In this embodiment, the difference from Embodiment 1 is that the second motor 4-2 is installed and fixed in the support 4-1, and the upper end of the second motor 4-2 is provided with a reducer 4-8, the reducer 4-8 is connected to the transmission mechanism through the universal joint 4-9, the universal joint 4-9 includes the active fork and the driven fork, the active fork is connected to the output shaft of the reducer 4-8, and the driven fork is vertical The installation panel of support 4-1 is installed, and connects the driving gear 4-4 in the transmission mechanism.

[0079]The driven fork has passed the mounting panel of the support 4-1, and a bearing needs to be installed at this position.

[0080] Perhaps this position is provided with an axle, and the installation panel installation of this axle vertical support 4-1. Driven fork connects the lower end of this axle, and driving gea...

Embodiment 3

[0085] In this embodiment, different from Embodiment 1, the synchronous drive mechanism includes two synchronous sprockets, the synchronous sprockets are respectively arranged on the first motor output shaft and the outer end fixed bracket, and the transmission chain is installed on the synchronous sprocket , the transmission chain is connected with the water outlet module.

[0086] The cross sections of the first column and the second column can be in various shapes such as rectangle, circle, ellipse, etc.

[0087] Other structures are the same as those in Embodiment 1, and will not be described again here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com