Cooking device

A technology of cooking equipment and pots, which is applied in the field of cooking equipment, can solve the problems of poor consistency of mechanism motion performance, high equipment energy consumption, large vibration and noise, etc., and achieve the goals of reducing cooking energy consumption, large heating area, and reduced volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

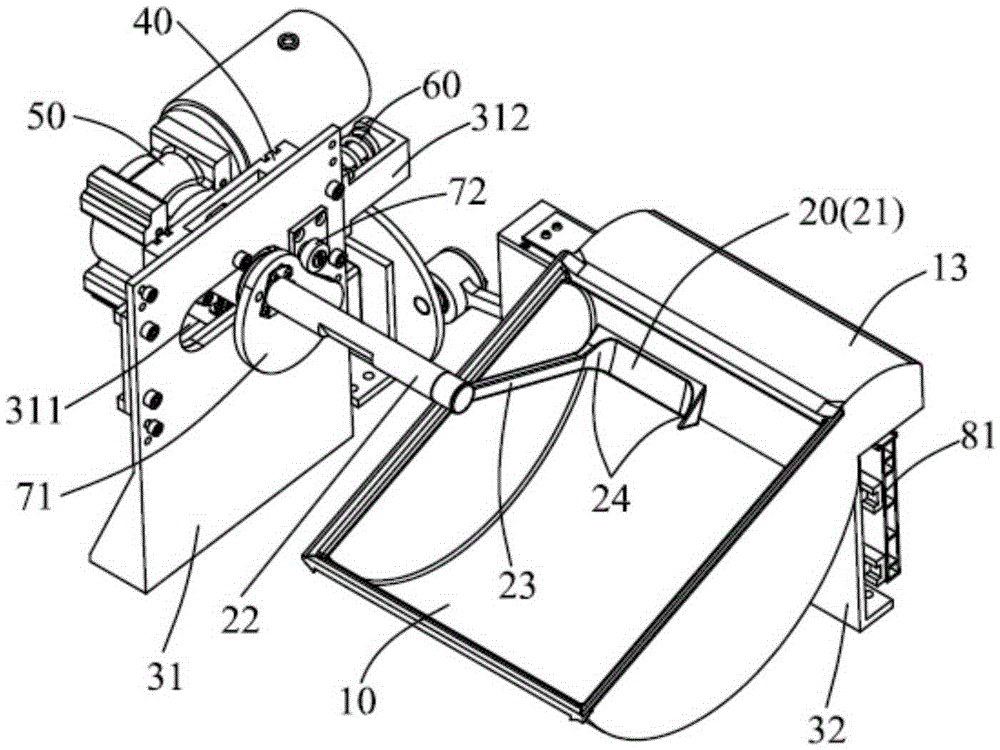

[0039] figure 1 and 2 It is a structural schematic diagram of Embodiment 1 of the cooking equipment of the present invention. Such as figure 1 As shown, the cooking equipment of this embodiment includes a frame 31, a pot 10, a stir-frying component 20 and a stir-frying motor 50 as a stir-frying power device. Wherein, the frame 31 is provided with a slider member 40, the stir-fry member 20 and the stir-fry motor 50 are arranged on the slider member 40; the rotating shaft 22 of the stir-fry member 20 passes through the strip hole 311 on the frame 31, and It is connected with the output shaft of the frying motor 50 through a coupling (not visible in the figure).

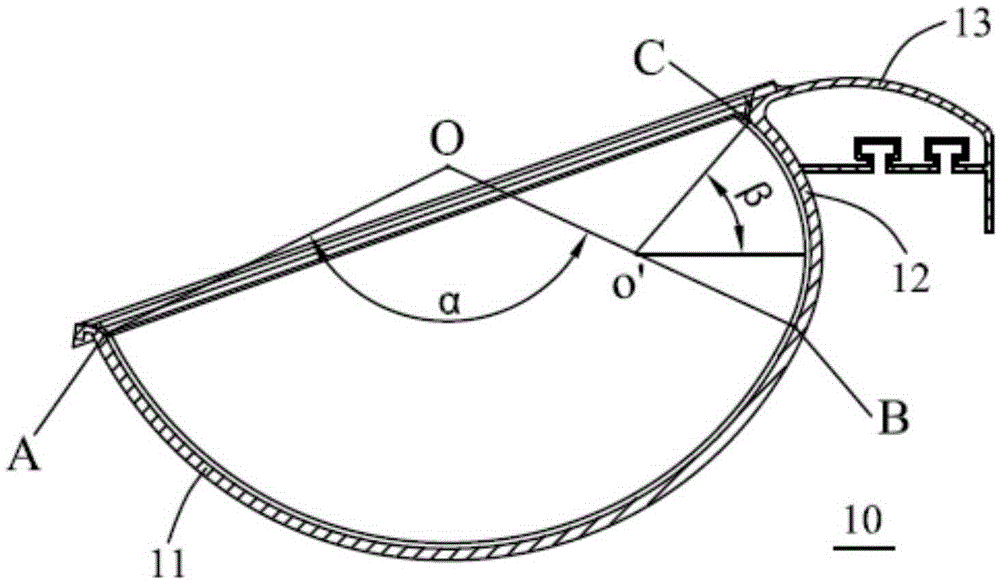

[0040] The pot 10 extends along its longitudinal direction and is roughly formed in a groove shape, and the inner contours of each cross section thereof are substantially the same. The stir-frying member 20 includes a working end 21 adapted to the inner wall of the pot 10, a connecting arm 23 connecting the working ...

Embodiment 2

[0049] Figure 7 and 8 It is a structural schematic diagram of Embodiment 2 of the cooking equipment of the present invention. Such as Figure 7 and 8 As shown, the cooking apparatus includes a pan 110 and a pan support 131 . Wherein, the pot support 131 has a guide rail 1311 and a guide rail 1312, the guide rail 1311 is provided with a slider member 111, the guide rail 1312 is provided with a slider member 181, and the side of the cooker 110 provided with the turning part is detachably supported on the slider. The opposite side of the block member 181 is rotatably connected to the slider member 111 . In this embodiment, the pot 110 also includes a pot body and a turning part. Since the structure of this part of the pot 110 is the same as that in Embodiment 1, a detailed description thereof is omitted here.

[0050] The cooking equipment also includes a pot shaking motor 190, a connecting rod member 182, and a crank member 183 connected with the pot shaking motor 190 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com