Four-wheel trolley chassis structure with suspension

A technology of small cars and chassis, which is applied in the direction of motor vehicles, vehicle parts, power plants, etc., can solve the problems of poor balance ability of the three-wheel system structure, weak passing ability, complex structure of the six-wheel system chassis, etc., and achieve a wide range of applications , low cost, smooth grip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

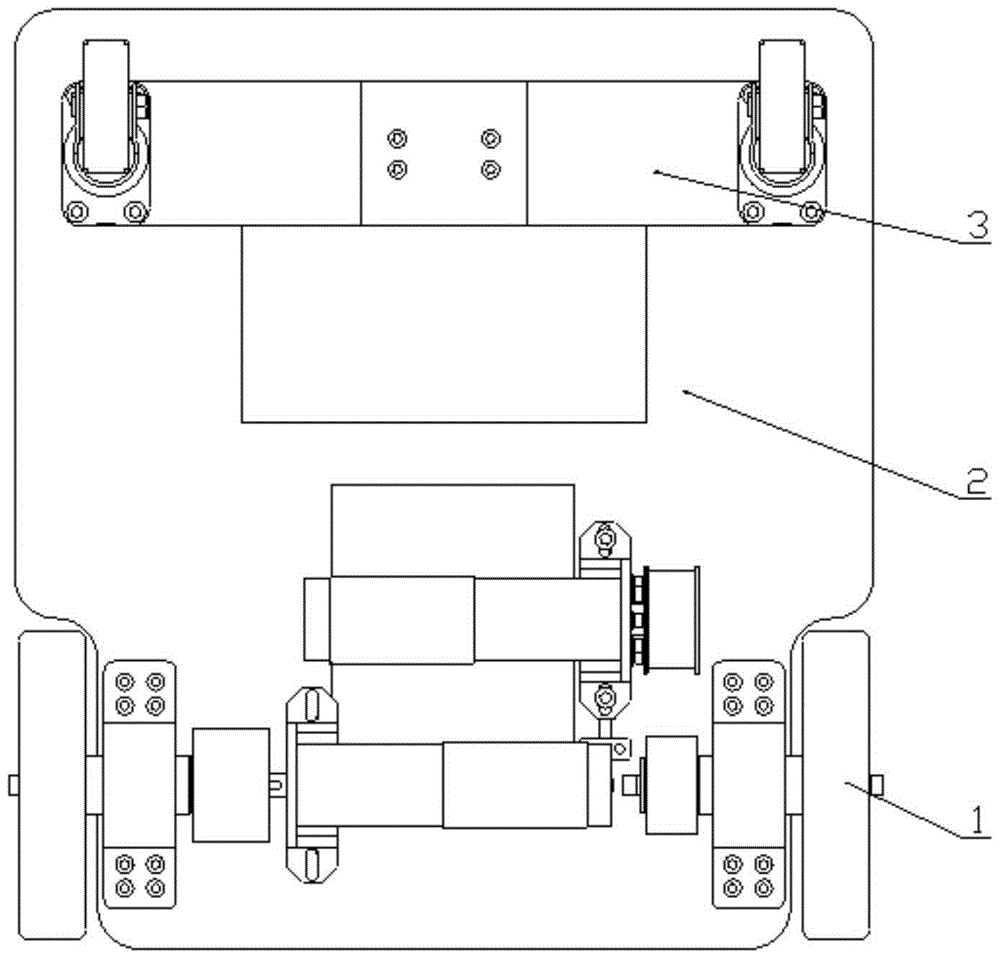

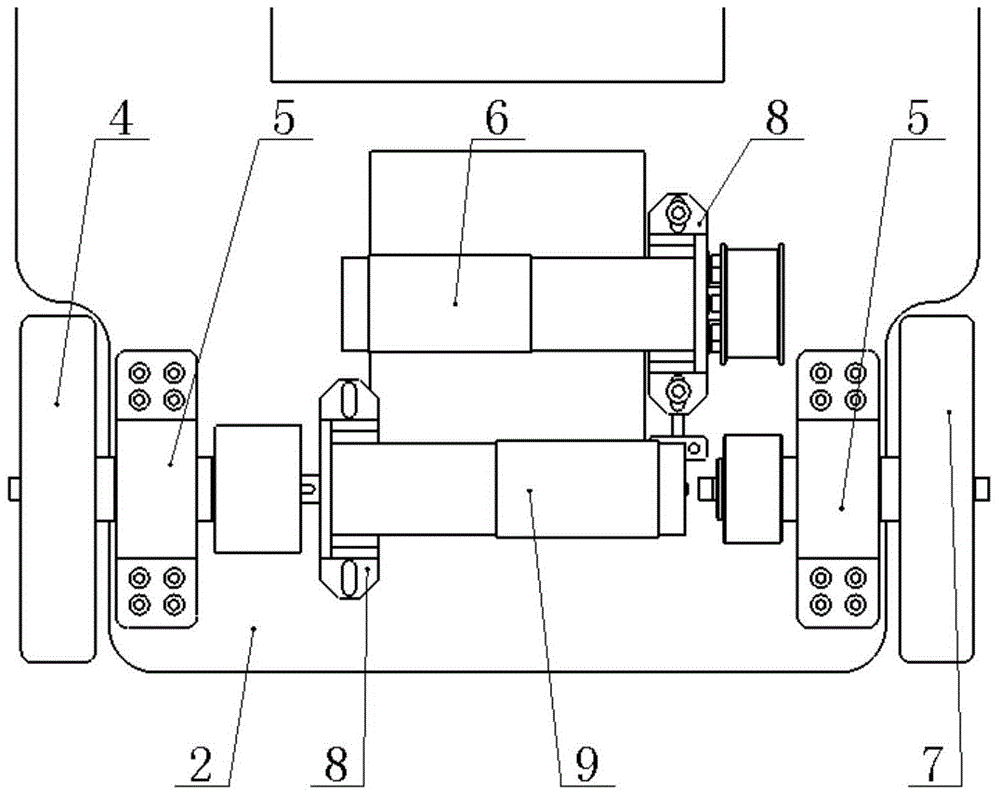

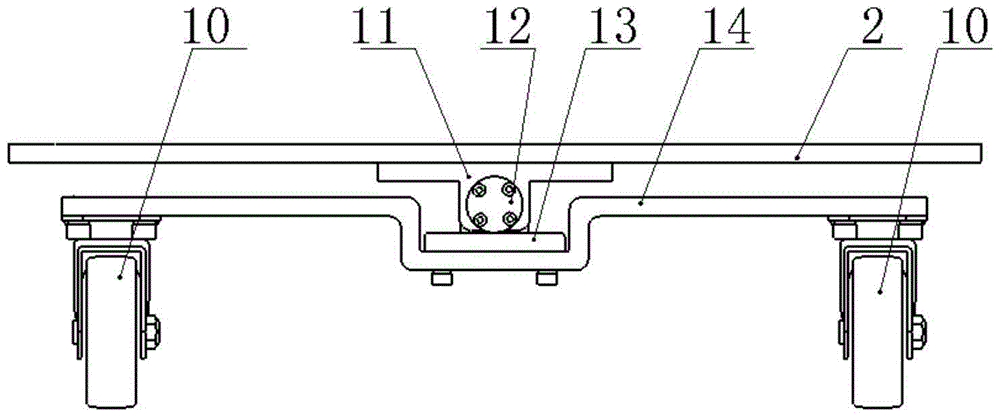

[0019] Such as figure 1 , 2 , shown in 3, a kind of belt suspension type four-wheel trolley chassis structure, comprises rear wheel drive assembly 1, base 2, front wheel suspension 3; Wherein rear wheel drive assembly 1 comprises right rear wheel train 4, rear wheel support Frame 5, left rear wheel system drive motor 6, left rear wheel system 7, drive motor seat 8, right rear wheel system drive motor 9; Front suspension shaft 12, front suspension lower bracket 13, elastic front beam 14;

[0020] The rear wheel drive assembly 1 is fixed on the base 2 by two rear wheel support frames 5 and two drive motor seats 8; the right rear wheel train 4 is connected with the right rear wheel train drive motor 9 through a coupling, and the left rear wheel The system 7 and the left rear wheel drive motor 6 form a rotational connection through a synchronous pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com