Composite driving system integrated by shearing type controllable damping and linear motor

A linear motor and drive system technology, applied in the direction of connection with the control/drive circuit, electric components, control mechanical energy, etc., can solve the problems of loss and consumption of satellite flipping off the track, and achieve accurate suppression of micro-vibration, good application prospects, and precise The effect of moving the position of the end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

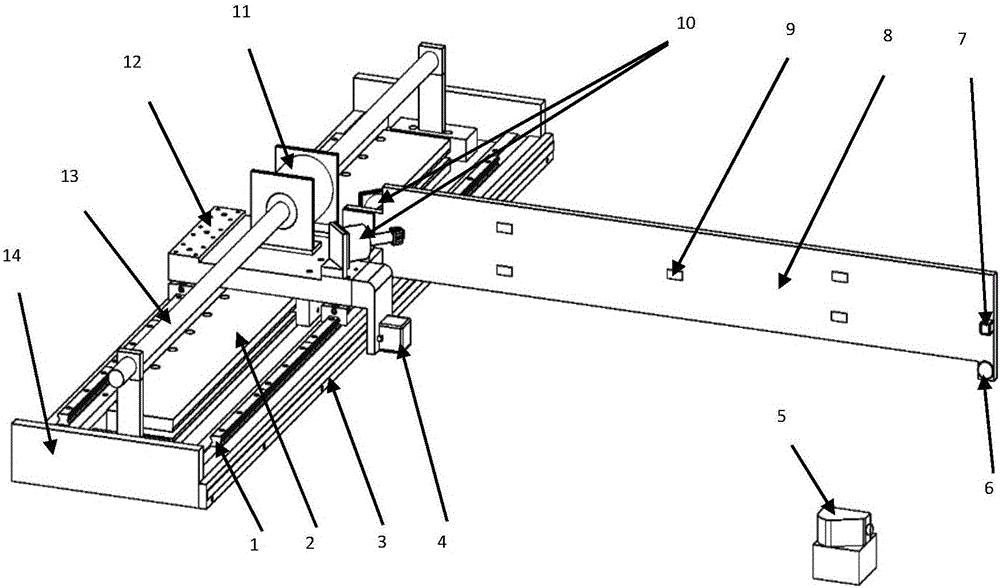

[0013] Such as figure 1 As shown, a composite drive system integrating shear type controllable damping and linear motor is characterized in that it includes base 14, linear motor 2, support base 12, fixed guide rod 13, drive damper 11, flexible arm load 8 , two support dampers 10 and a laser displacement sensor 5;

[0014] There are two parallel precision guide rails 1 on the base 11, the support base 12 is installed on the two precision guide rails 1, the linear motor 2 is installed on the base 14, and the output end is connected with the support base 12 to drive the support base 12 Slide along the precision rail 1;

[0015] Both ends of the fixed guide rod 13 are fixed on the base 14 and parallel to the precision guide rail 1;

[0016] The driving damper 11 is installed on the fixed guide rod 13, and the lower end is fixedly connected with the top surface of the support seat 12, so as to improve the motion performance;

[0017] The flexible arm load 8 is horizontally fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com