Panel/tape zone coal pillar integrated coal mining system

A coal pillar and panel technology, which is applied in the field of coal mining and mining systems, can solve problems such as difficulty in recovering coal pillars, and achieve the effects of solving the difficulty in recovering coal pillars and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

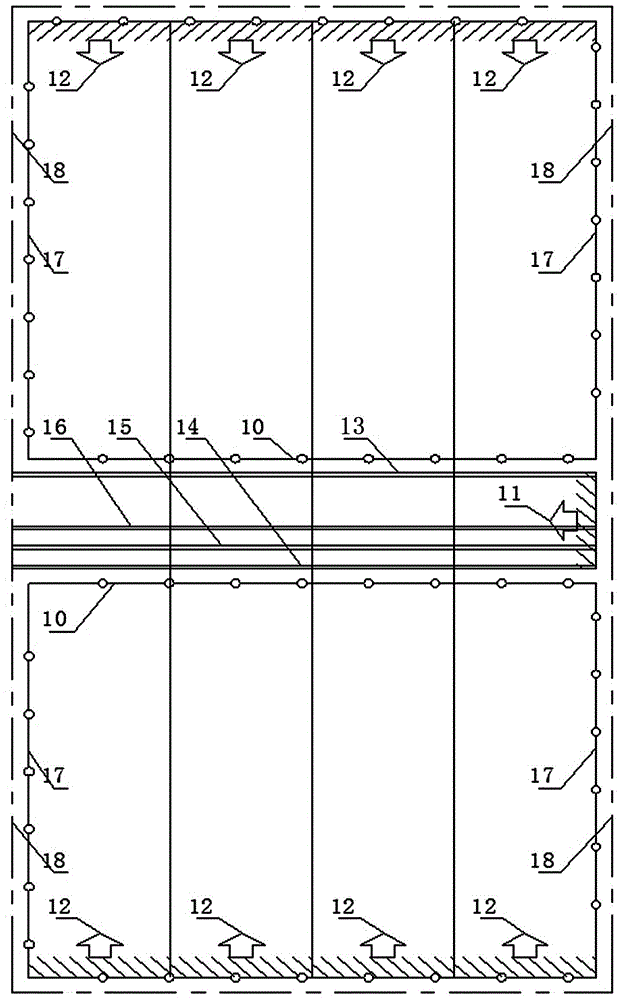

[0018] The integrated coal mining system of panel / belt coal pillar mining is realized by the following steps:

[0019] Step A: leave a roadway protection coal pillar with a width of 100m outside the original return airway; leave a roadway protection coal pillar with a width of 20m outside the original transportation roadway;

[0020] Step B: arrange the mining face according to the normal mining procedure, and then arrange the coal pillar recovery roadway; the coal pillar recovery roadway is arranged inside the coal pillar of the roadway protection outside the return air roadway;

[0021] Step C: After the mining of the mining face is completed, use the original air return roadway, the original track roadway, the original transportation roadway and the coal pillar recovery roadway to arrange the recovered coal pillar working face with a width of 140m, thus utilizing the comprehensive The mining technology recovers the coal pillars between the transport roadway and the coal pil...

Embodiment 2

[0024] The integrated coal mining system of panel / belt coal pillar mining is realized by the following steps:

[0025] Step A: leave a roadway protection coal pillar with a width of 100m outside the original return airway; leave a roadway protection coal pillar with a width of 20m outside the original transportation roadway;

[0026] Step B: arrange the mining face according to the normal mining procedure, and then arrange the coal pillar recovery roadway; the coal pillar recovery roadway is arranged inside the coal pillar of the roadway protection outside the return air roadway;

[0027] Step C: After the mining of the mining face is completed, use the original air return roadway, the original track roadway, the original transportation roadway and the coal pillar recovery roadway to arrange the recovered coal pillar working face with a width of 140m, thus utilizing the comprehensive The mining technology recovers the coal pillars between the transport roadway and the coal pil...

Embodiment 3

[0030] The integrated coal mining system of panel / belt coal pillar mining is realized by the following steps:

[0031] Step A: leave a roadway protection coal pillar with a width of 100m outside the original return airway; leave a roadway protection coal pillar with a width of 20m outside the original transportation roadway;

[0032] Step B: arrange the mining face according to the normal mining procedure, and then arrange the coal pillar recovery roadway; the coal pillar recovery roadway is arranged inside the coal pillar of the roadway protection outside the return air roadway;

[0033] Step C: After the mining of the mining face is completed, use the original air return roadway, the original track roadway, the original transportation roadway and the coal pillar recovery roadway to arrange the recovered coal pillar working face with a width of 140m, thus utilizing the comprehensive The mining technology recovers the coal pillars between the transport roadway and the coal pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com