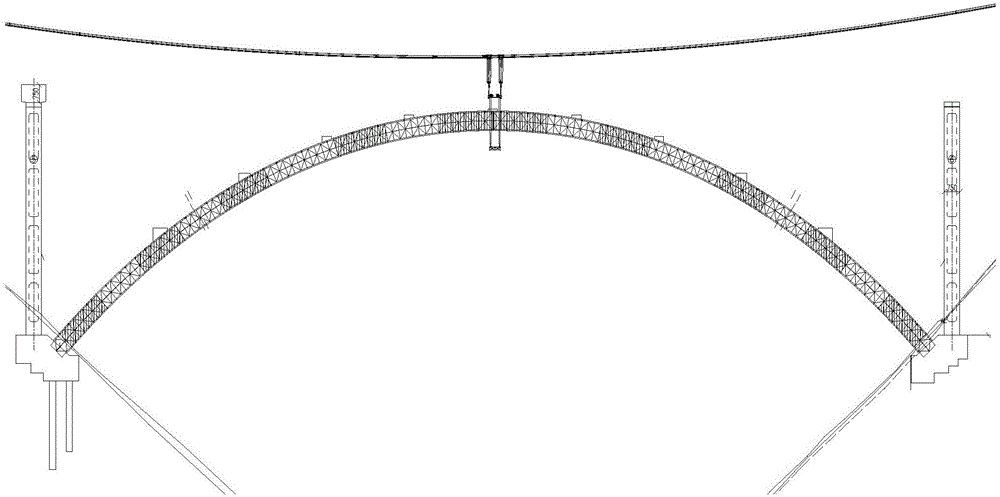

Large-height-difference long-span stiff-skeleton cladding concrete formwork construction method and apparatus

A technology of outsourcing concrete and rigid skeleton, which is applied in the field of formwork/formwork/work frame, preparation of building components on site, construction, etc., which can solve the problems of low utilization rate of formwork, high construction safety risk, and formwork removal, etc., to achieve High-precision installation, the effect of reducing the risk of work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The three groups of Baileys are 30m long, and the distance between each group of Baileys is 3m. Each group of Baileys is connected by [12 channel steel, which acts as the main stress system of the bottom operation platform.

[0034] The bottom platform is fixed on the bottom of the Bailey sheet with [12 channel steel 1m / way, and the top of the channel steel is covered with wooden boards (specification: 400*30*4cm) and fixed firmly with steel bars as a whole, which functions as a personnel operating platform during the formwork installation process .

[0035] The top platform is connected with the Bailey sheet by using [12 channel steel 1m / channel on the top of the Bailey sheet, and it functions as a platform for the formwork to be placed.

[0036] The pole beam is welded by double I28 I-beams. There are two pieces in total, one for each of the two sections of the Bailey beam; the two sections on the top of the pole beam are provided with lifting lugs, which are made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com