Position and posture control method for planar 4R under-actuation mechanical arm

A control method and under-actuated technology, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems that affect the control effect and accuracy, and are not conducive to the precise control of under-actuated manipulators, so as to avoid cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] S1 build ADAMS virtual prototype model;

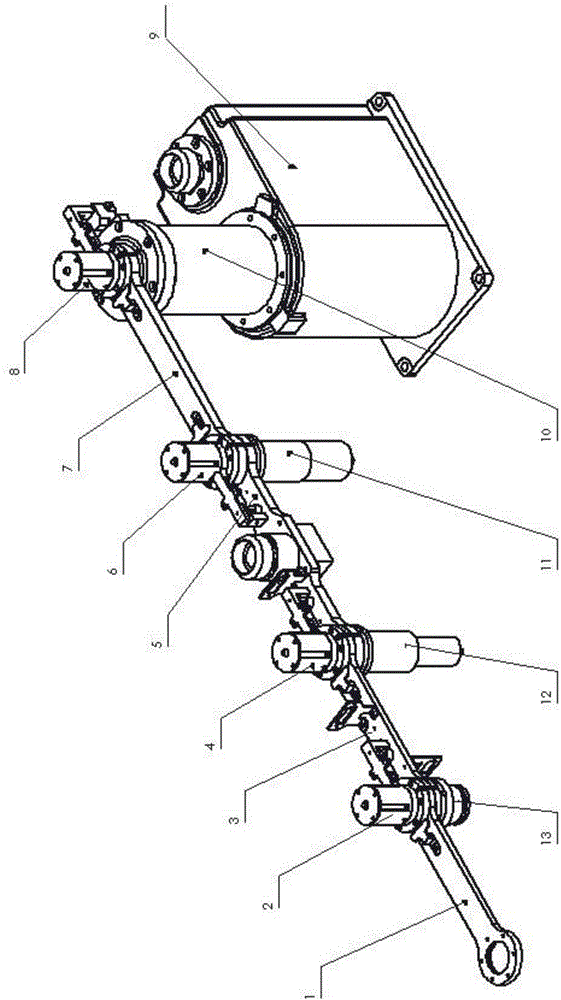

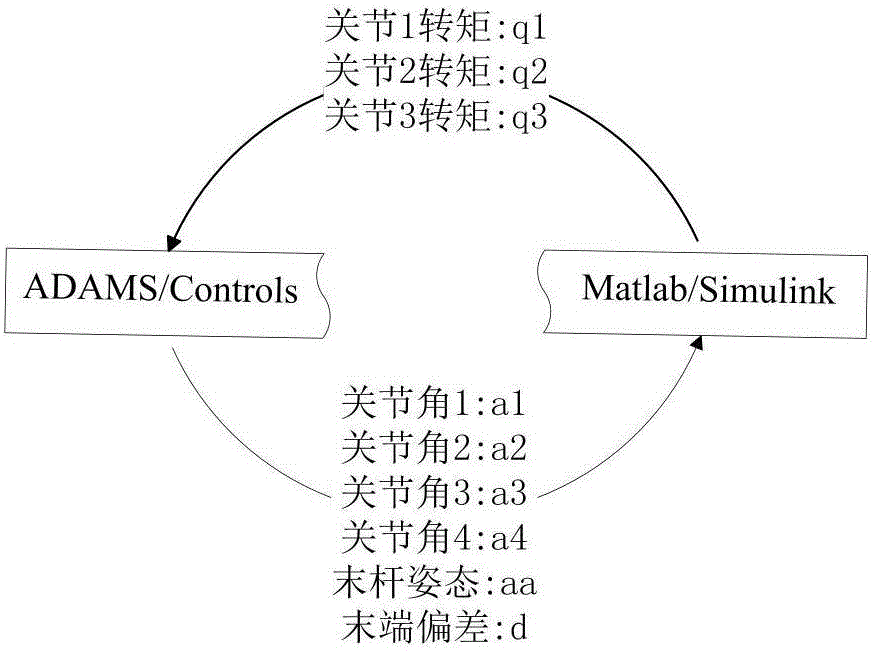

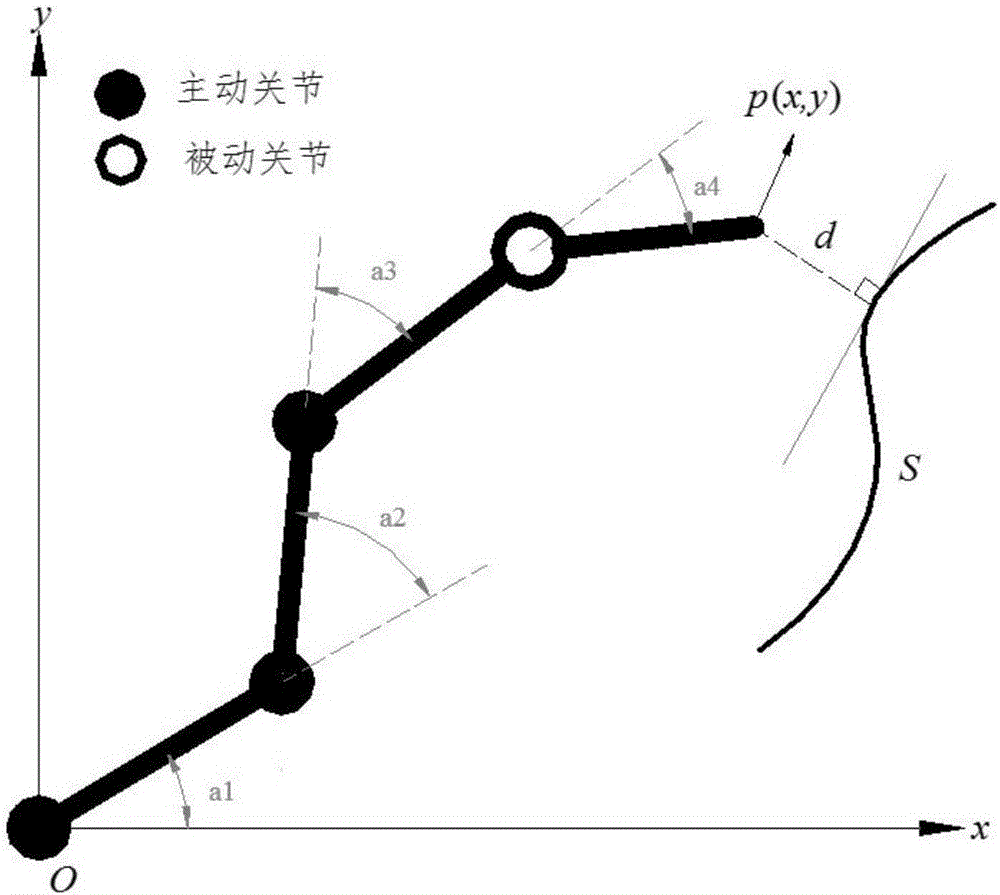

[0025] Due to the relatively weak ability of ADAMS to model complex mechanical models, SolidWorks 3D design software was chosen to establish a 3D mechanical model of the horizontal underactuated manipulator, which was saved in Parasolid format and then imported into ADAMS. Edit the properties of each part in the ADAMS software, define the physical properties such as the quality, material, and friction coefficient of each joint of each part; then add fixed constraints between the base 9 and the ground, and add rotating pairs on the four joints, Finally, torque is added to the revolving pairs of the first three joints to replace the input torque of the motor, and no torque is added to the fourth revolving pair to indicate that the joint is a free joint; considering the friction of each joint on the movement of the mechanical arm The effect of adding friction dampers to the joints is closer to the real physical properties. The vir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com