Shellfish shell opening device

A shellfish and heating device technology, which is applied in the processing of crustaceans, slaughtering, shrimp/lobster processing, etc., can solve the problems of reducing economic value, leaving scallop pillars, and not being able to obtain breeding and processing households

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

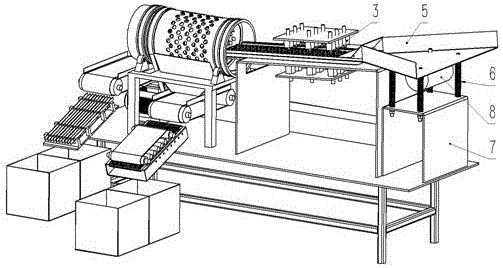

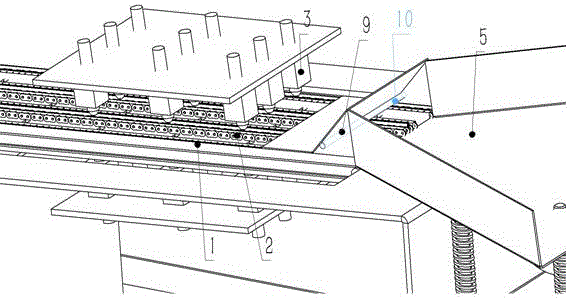

[0013] according to figure 1 and figure 2 As shown, the present invention is specifically a shellfish shell opening device, including a feeding device, a conveying device and a heating device, the feeding device includes a feeding hopper and a spring assembly 6 and a support 7 supporting the feeding hopper, and the feeding hopper The lower part is provided with a vibrator 8, which makes the shellfish enter the conveying device through vibration. The outlet of the feeding hopper is provided with a baffle plate and a height limit rod. The baffle plate 9 prevents the shellfish from falling from the side during the vibration process. The height limit rod 10 can guarantee that only one shellfish enters in the conveying device in the longitudinal direction.

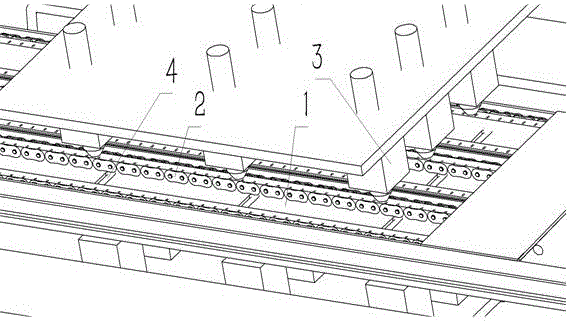

[0014] The conveying device comprises a supporting plate 1 and several conveying chain groups 2 arranged on the supporting plate, and each group of conveying chain groups is next to each other, and the transmission starting e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com