A method for loading and unloading a large liquid crystal panel

A liquid crystal panel, large-scale technology, used in instruments, nonlinear optics, optics, etc., can solve problems such as excessive machine length, scrap, damage to panels and microscopes, and achieve the effect of stable running trajectory and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

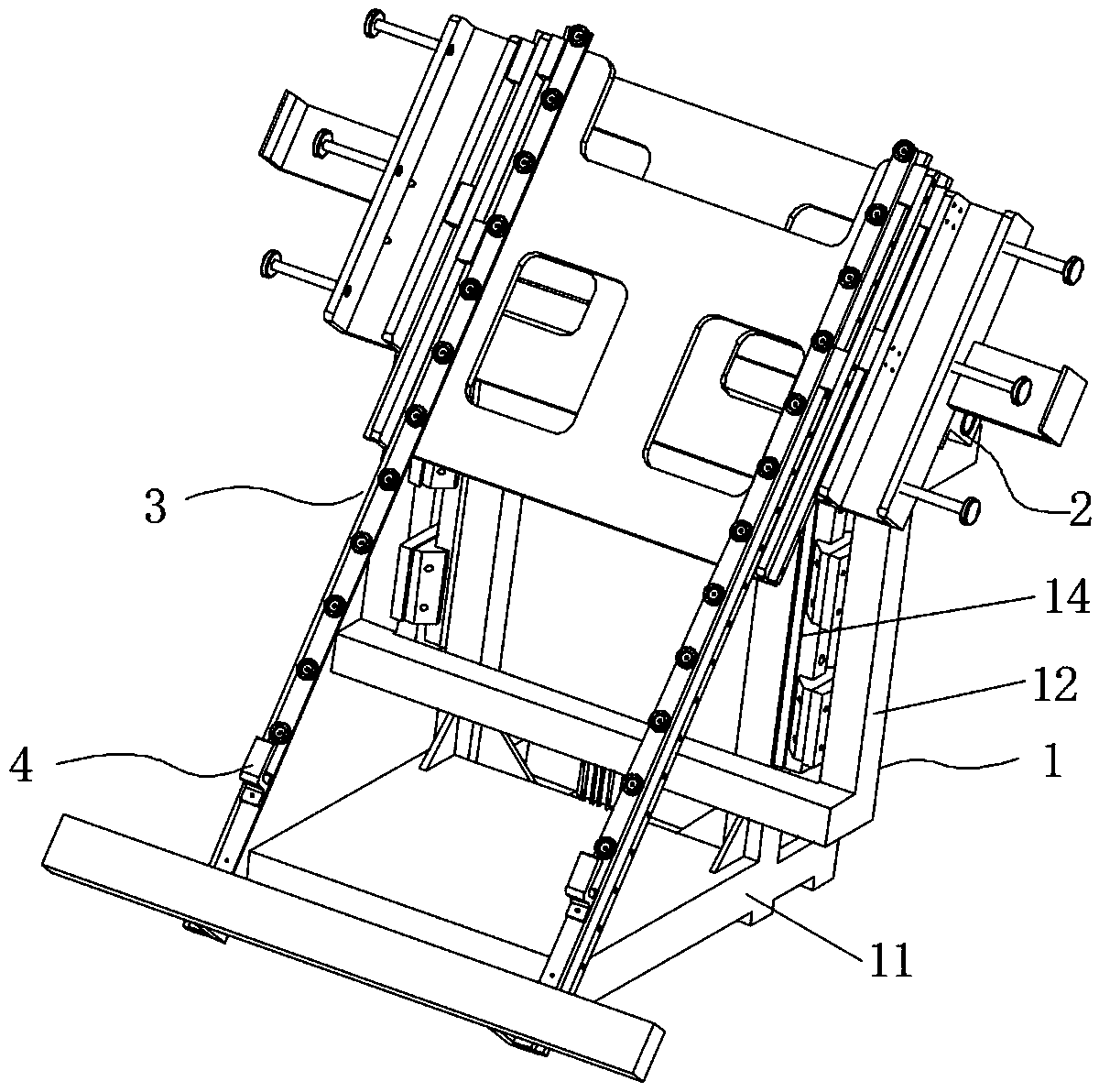

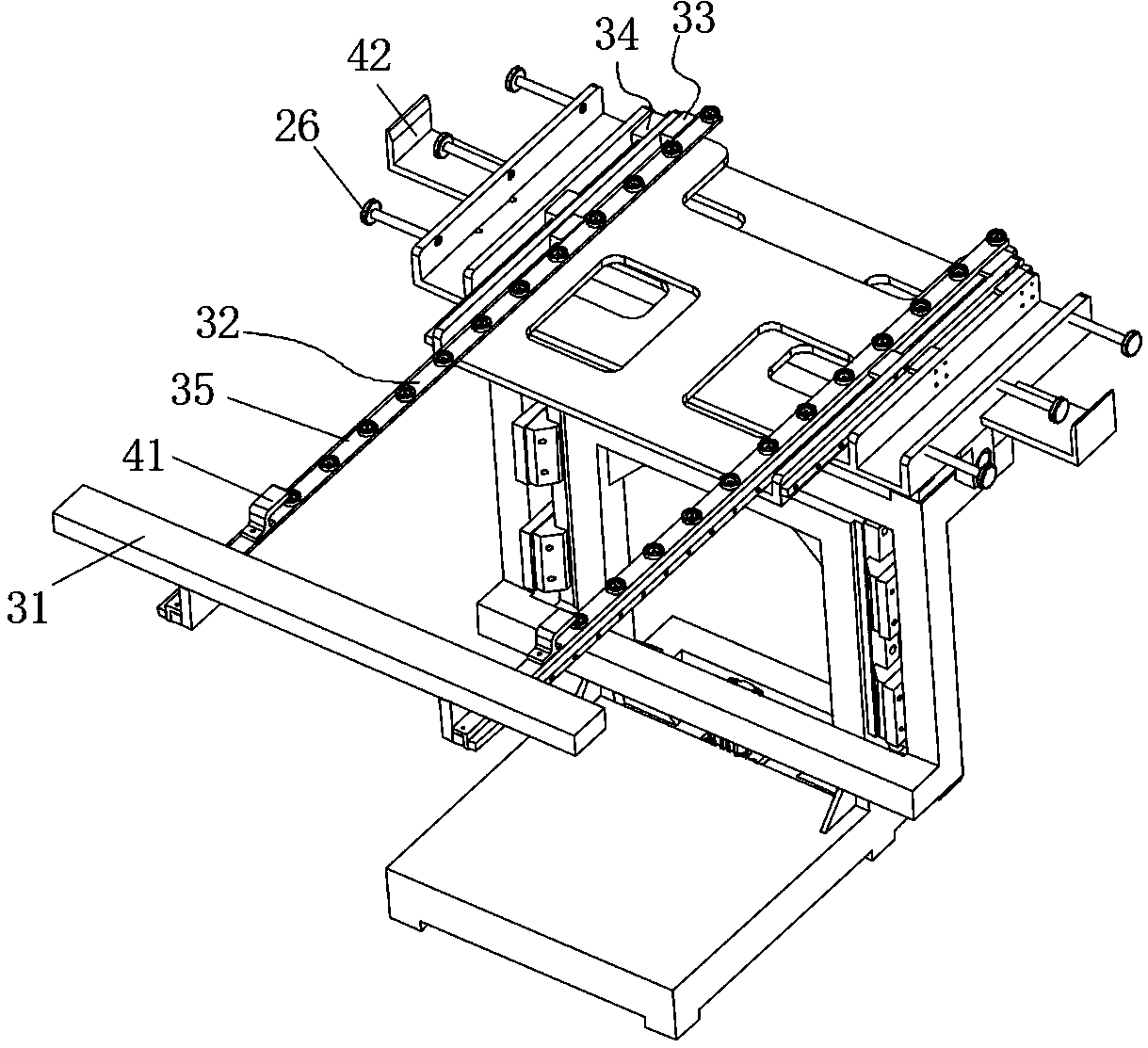

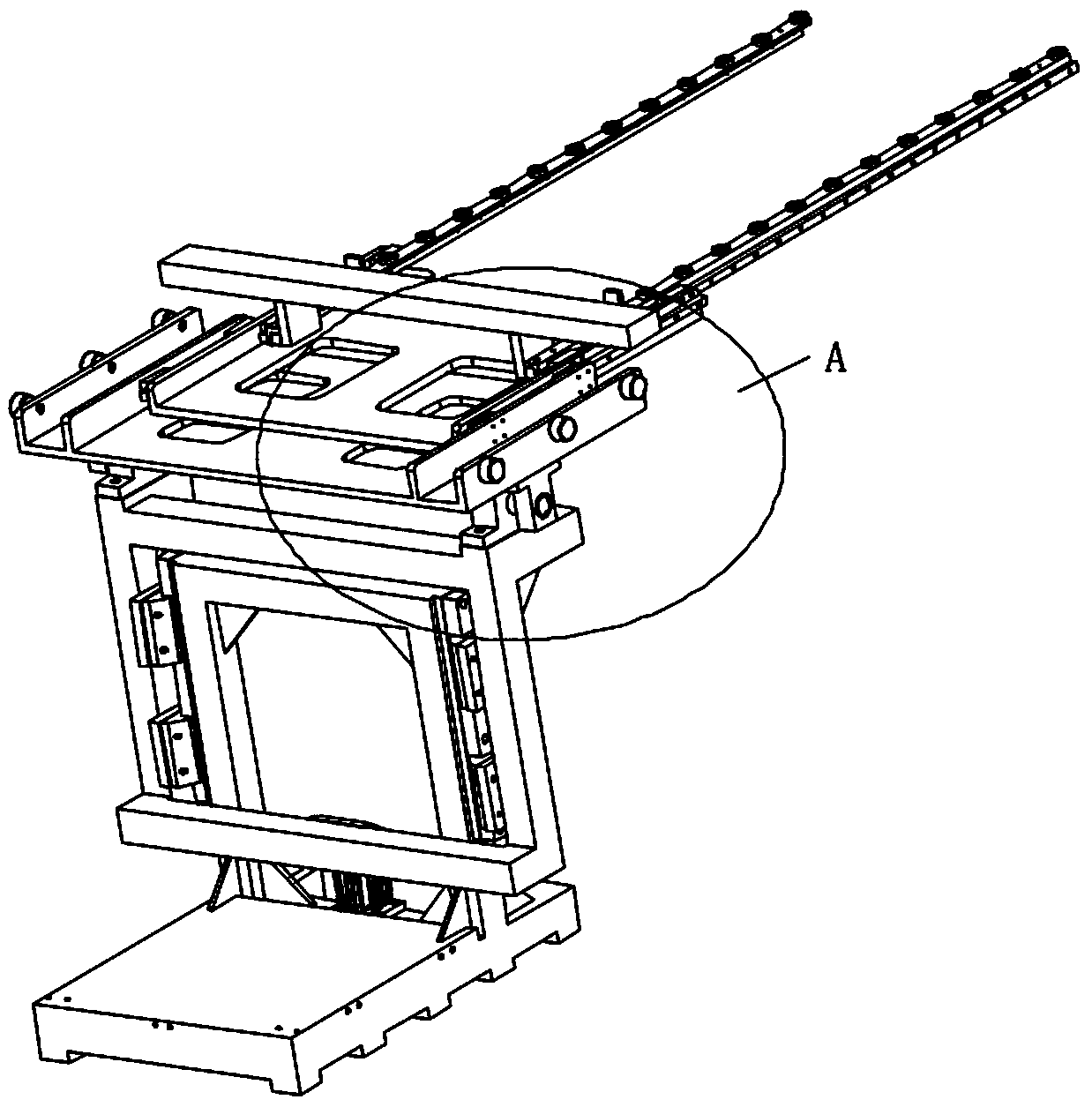

[0032] Examples, see Figure 1~4 , the method for loading and unloading a large liquid crystal panel provided in this embodiment comprises the following steps:

[0033] (1) fixed seat 1 is set, and this fixed seat 1 comprises base 11 and vertical support 12, and flipping mechanism and horizontal push mechanism 3 are set on fixed seat 1 vertical support 12; Large liquid crystal panel is set on described horizontal push mechanism 3 positioning member 4;

[0034] Described overturning mechanism comprises overturning bottom plate 21, overturning base 2211 and overturning support 23, and described vertical support 12 tops are provided with horizontal installation part 13, and described overturning base 2211 is fixedly provided with the upper end of horizontal installation part 13, and described overturning support 23 is fixed Connected to the lower end of the overturning base plate 21, the horizontal pushing mechanism 3 is movably arranged on the overturning base plate 21; The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com