Dehydration Sensitive Time Indicating Device

A technology of indicating device and time-sensitive, applied in measuring device, material analysis and instrument by observing the influence of chemical indicator, can solve the problems of external environmental pollution, restricted use environment, and the indication effect is easily affected by the external environment, etc. , to avoid the effect of discoloration cycle, high precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

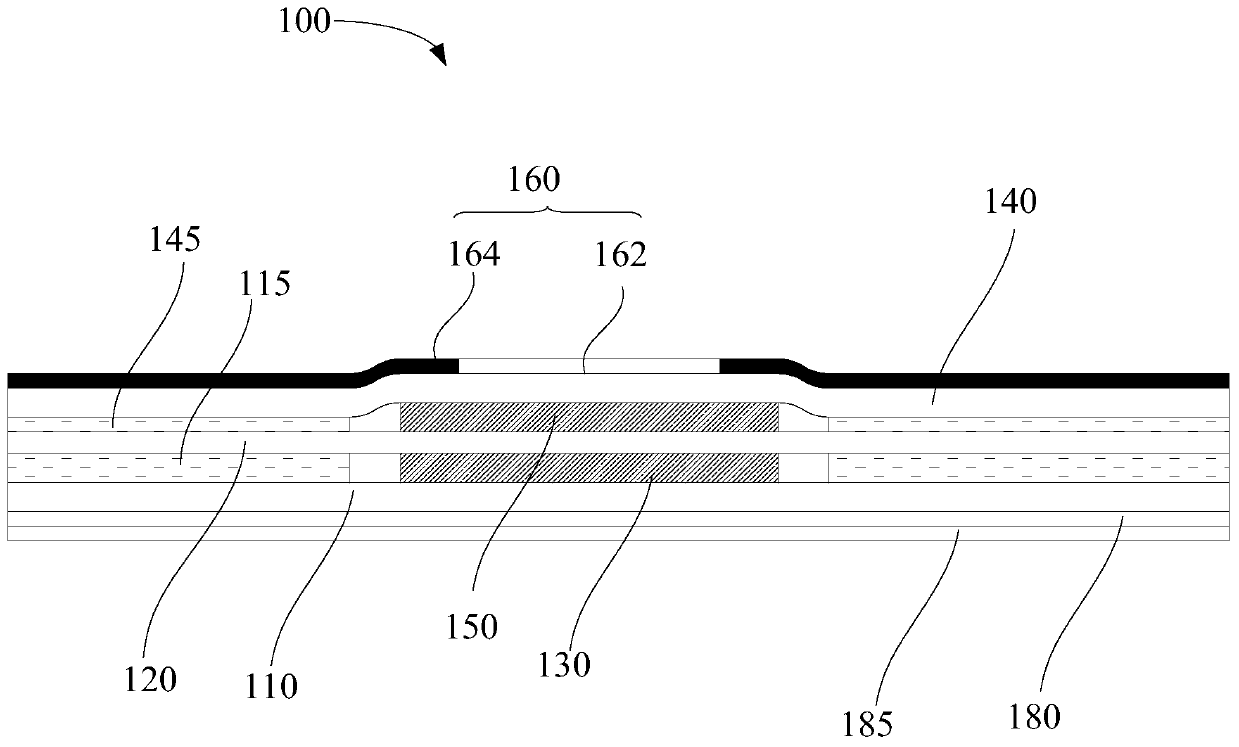

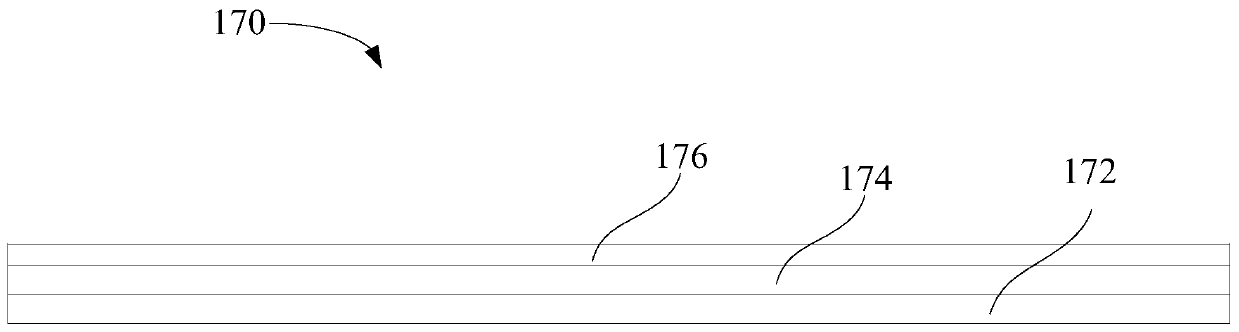

[0089] The structure of the water loss sensitive time indicating device of Example 1 is as follows figure 1 As shown, it includes a base layer 110, a first substrate layer 120, a dry adsorption layer 130, a second substrate layer 140, an indicator function layer 150, a comparison layer 160, an adhesive layer 180, and a peeling layer 185. The barrier component 170 includes a barrier layer 172, an adhesive layer 174, and a protective layer 176 stacked in sequence.

[0090] Wherein, the material of the base layer 110 is a PET film with a thickness of 18 μm. The material of the first base material layer 120 is a PET film with a thickness of 18 μm.

[0091] The dry adsorption layer 130 includes 10 g of calcium chloride, and the thickness of the dry adsorption layer 130 is 1 mm.

[0092] The edge area of the base layer 110 and the edge area of the first substrate layer 120 are sealed together to form an adhesive portion 115.

[0093] The material of the second base layer 140 is a PET f...

Embodiment 2

[0103] The structure of the water loss sensitive time indicating device of embodiment 2 is as follows figure 1 As shown, it includes a base layer 110, a first substrate layer 120, a dry adsorption layer 130, a second substrate layer 140, an indicator function layer 150, a comparison layer 160, an adhesive layer 180, and a peeling layer 185. The barrier component 170 includes a barrier layer 172, an adhesive layer 174, and a protective layer 176 stacked in sequence.

[0104] Wherein, the material of the base layer 110 is a PET film with a thickness of 18 μm. The material of the first base material layer 120 is a PET film with a thickness of 18 μm.

[0105] The dry adsorption layer 130 includes 1 g of calcium oxide, and the thickness of the dry adsorption layer 130 is 1 mm.

[0106] The edge area of the base layer 110 and the edge area of the first substrate layer 120 are sealed together to form an adhesive portion 115.

[0107] The material of the second base layer 140 is a PET fi...

Embodiment 3

[0116] The structure of the water loss sensitive time indicating device of embodiment 3 is as follows Image 6 As shown, it includes a base layer 210, a first substrate layer 220, a dry adsorption layer 230, a second substrate layer 240, an indicator function layer 250, a comparison layer 260, an adhesive layer 280, a release layer 285, and an auxiliary layer 310. The barrier component 170 includes a barrier layer 172, an adhesive layer 174, and a protective layer 176 stacked in sequence.

[0117] Wherein, the material of the base layer 210 is a PET film with a thickness of 18 μm. The material of the first substrate layer 220 is a PET film, and the thickness is 18 μm.

[0118] The dry adsorption layer 130 includes 3 g of silica gel desiccant, and the thickness of the dry adsorption layer 130 is 1 mm.

[0119] The edge area of the base layer 210 and the edge area of the first substrate layer 220 are sealed together to form an adhesive portion 215.

[0120] The material of the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com