Universal type shrimp cage structure for catching and transporting

A general-purpose, shrimp cage technology, applied in the field of shrimp cages, can solve the problems of increasing shrimp crushing damage and stress response, hindering the survival rate of transportation, troublesome operation, etc. The effect of shrimp convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

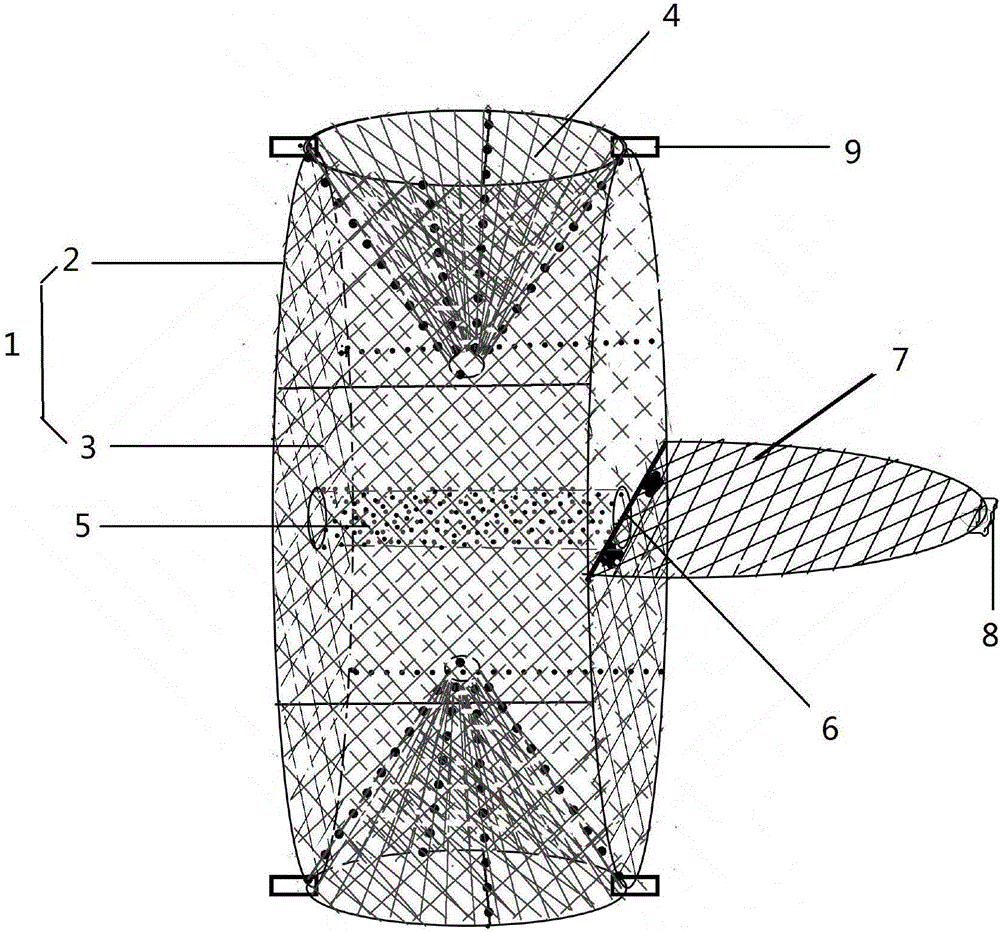

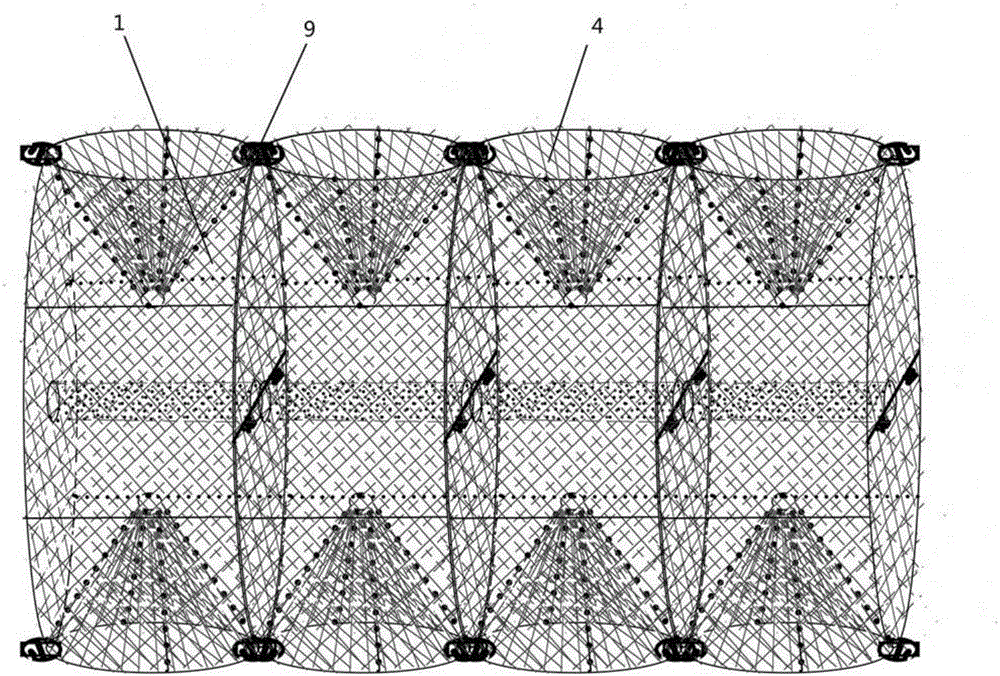

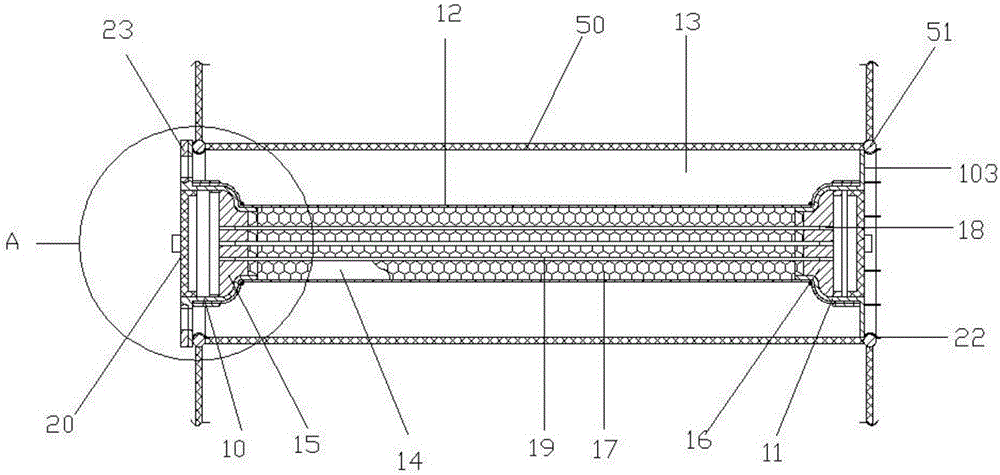

[0021] Such as figure 1 A kind of general-purpose shrimp cage structure for catching and transporting shown includes a shrimp cage body 1, and the shrimp cage body includes a cylindrical shrimp cage skeleton 2, a mesh 3 coated on the shrimp cage skeleton, and the sides of the shrimp cage body are at least Be provided with a shrimp net tube 4, the shrimp net tube is a circular frustum structure, the large diameter end of the shrimp net tube 4 is connected with the outer space of the shrimp cage body, and the small diameter end of the shrimp cage body 4 is connected with the inside of the shrimp cage body. The space is connected, the shrimp cage body is provided with a bait groove 5, and the center of an end face of the shrimp cage body is provided with a radially distributed rotating shaft 6, and the rotating shaft is provided with a shrimp-taking doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com