A method of detecting surface lithium of a ternary cathode material

A positive electrode material and detection method technology, which is applied in the direction of chemical analysis by titration method, can solve the problems of large detection errors of lithium carbonate and lithium hydroxide, achieve the effects of short detection time, reduce errors, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The detection method of the lithium on the surface of the ternary positive electrode material of the present embodiment is to measure the lithium on the surface of the ternary positive electrode material of 622, comprising the following steps:

[0029] 1) Weigh 30g of sample into a 250ml beaker, add 100mL of deionized water, stir on a magnetic stirrer for 30min, then let it stand for 30min, vacuum filter with a 0.45μm microporous membrane, and the filtrate is the sample to be tested solution;

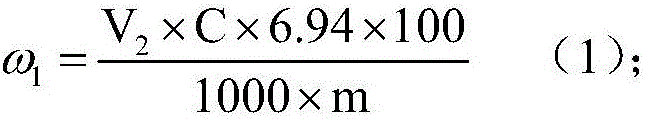

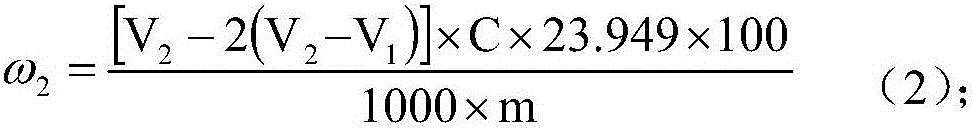

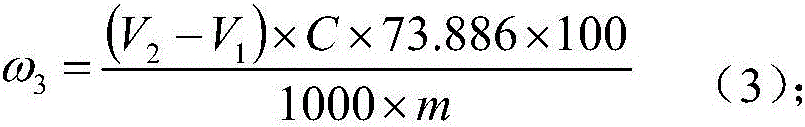

[0030] 2) Take 20mL of filtrate into a 100mL Erlenmeyer flask, place the Erlenmeyer flask on a magnetic stirrer, add two drops of phenolphthalein indicator first, the solution to be tested turns red, and then titrate with 0.1mol / L standard hydrochloric acid solution to Colorless, record the volume V of standard hydrochloric acid solution consumed 1 (mL), then add 5 drops of methyl red indicator, the system turns yellow, titrate to orange with standard hydrochloric acid solution,...

Embodiment 2

[0042] The detection method of the lithium on the surface of the ternary positive electrode material of the present embodiment is to measure the lithium on the surface of the ternary positive electrode material of 622, comprising the following steps:

[0043] 1) Weigh 30g of sample into a 250ml beaker, add 100mL of deionized water, place it on a magnetic stirrer and stir for 40min, then let it stand for 30min, vacuum filter with a 0.45μm microporous membrane, and the filtrate is the sample to be tested solution;

[0044] Step 2), step 3) are identical with embodiment 1.

Embodiment 3

[0046] The detection method of the lithium on the surface of the ternary positive electrode material of the present embodiment is to measure the lithium on the surface of the ternary positive electrode material of 622, comprising the following steps:

[0047] 1) Weigh 30g of sample into a 250ml beaker, add 100mL of deionized water, stir on a magnetic stirrer for 60min, then let it stand for 30min, vacuum filter with a 0.45μm microporous membrane, and the filtrate is the sample to be tested solution;

[0048] Step 2), step 3) are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com