Polyethylene composition and inflaming-retarding thin film

A technology of flame-retardant film and polyethylene, which is applied in the field of polyethylene composition and flame-retardant film, and can solve the problems of easy cracking of the film, poor flame-retardant performance of polyethylene film, and poor film-forming property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

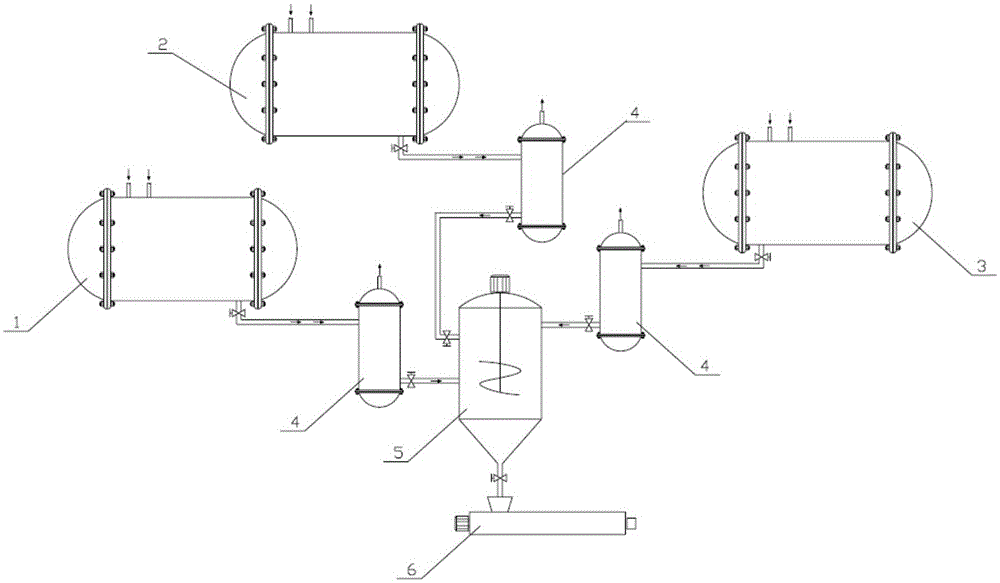

[0029] According to a preferred embodiment of the present invention, the polyethylene composition is figure 1 Prepared in the shown multi-reactor parallel device, described multi-reactor parallel device comprises first reactor 1, second reactor 2, third reactor 3, solid / liquid (gas) separator 4, homogenizer The silo 5 and the melt granulation system 6, wherein the first reactor 1, the second reactor 2 and the third reactor 3 are connected in parallel, and the number of the solid / liquid (gas) separator 4 is three One, communicated with the first reactor 1, the second reactor 2 and the third reactor 3 respectively, the component A produced by the first reactor 1, the component B produced by the second reactor 2 and the component B produced by the third reactor The component C prepared by the reactor 3 is carried out phase separation in different solid / liquid (gas) separators 4 respectively, and then the component A, component B and component C after the phase separation will be ...

Embodiment 1

[0045] This example is used to illustrate the polyethylene composition and the flame retardant film provided by the present invention.

[0046] (1) Preparation of polyethylene composition:

[0047] The polyethylene composition provided in this example is composed of Component A, Component B, Component C and a flame retardant. Ethylene (LLDPE), wherein, component A and component B are prepared using metallocene catalyst (the metallocene catalyst system is the loaded metallocene catalyst prepared by CN102453124A embodiment 1, the same below), and component C is prepared by A Ziegler-Natta catalyst was prepared (the Ziegler-Natta catalyst system is the Ziegler-Natta catalyst system prepared in Example 1 of CN101838351A, the same below). Specific steps are as follows:

[0048] Add ethylene, α-olefin, hydrogen and nitrogen (ethylene, α-olefin, hydrogen and nitrogen are of polymerization grade, used after removing water and oxygen, the same below) into the fluidized bed gas phase ...

Embodiment 2

[0059] This example is used to illustrate the polyethylene composition and the flame retardant film provided by the present invention.

[0060] (1) Preparation of polyethylene composition:

[0061] The polyethylene composition provided in this example is composed of Component A, Component B, Component C and a flame retardant. Ethylene (LLDPE), wherein, components A and B are prepared using metallocene catalysts, and component C is prepared using Ziegler-Natta catalysts. Specific steps are as follows:

[0062] Add ethylene, alpha olefin, hydrogen and nitrogen into the fluidized bed gas phase reactor, then add the catalyst system, and then polymerize under the conditions of temperature 84-88°C and pressure 1.8-2.0MPa to obtain components A, Component B and Component C. Among them, the control of the melt index of component A, component B and component C is realized by adjusting the amount of hydrogen added, and the control of density is realized by adjusting the type and amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com