A negative pressure ignition separation device

A separation device and negative pressure technology, applied in the field of solid fuel stoves, can solve the problems of poor fuel combustion, affecting heat exchange, flue gas discharge, and dust adhesion, etc., to reduce the generation of harmful substances, improve combustion efficiency, The effect of eliminating leakage hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

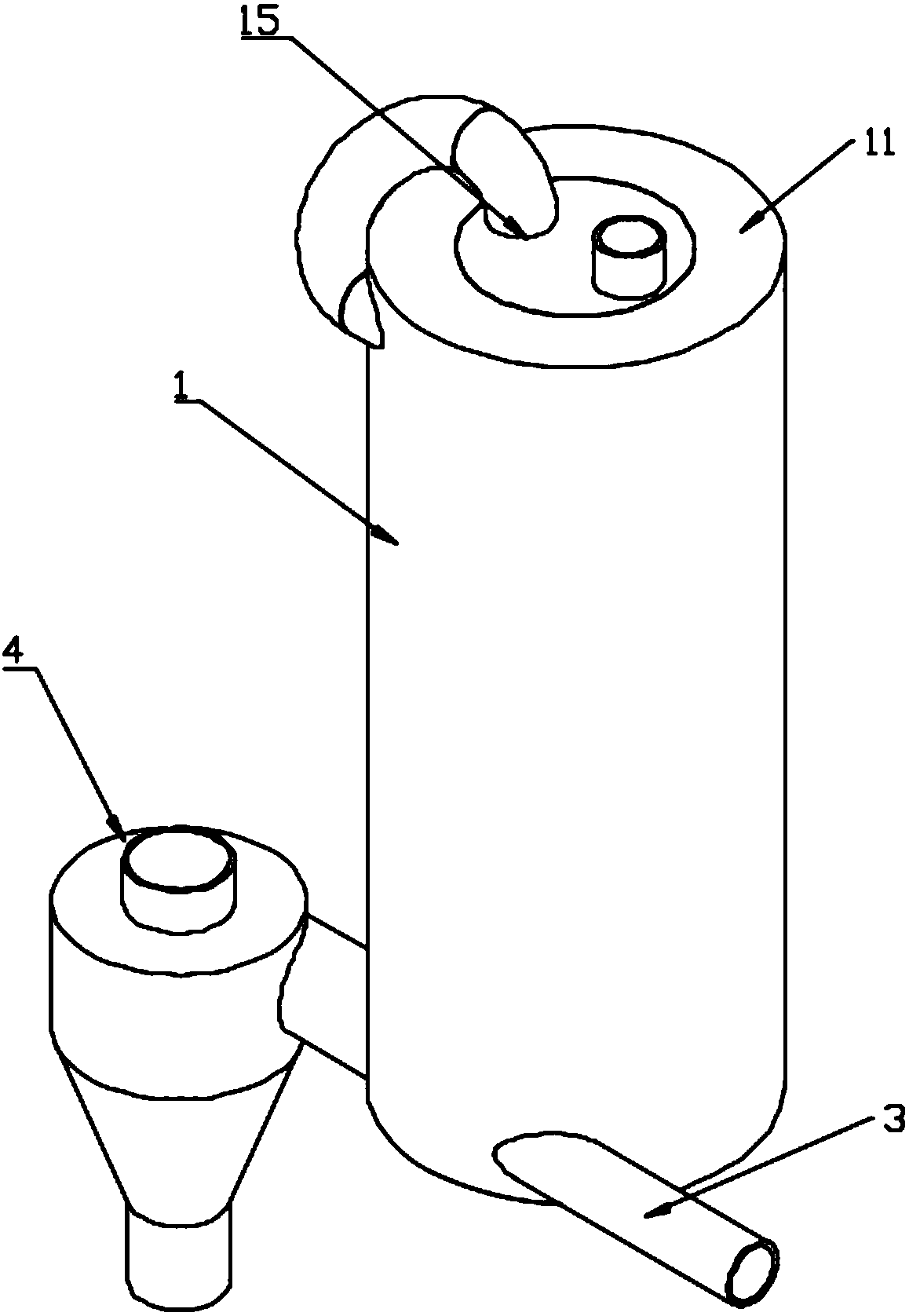

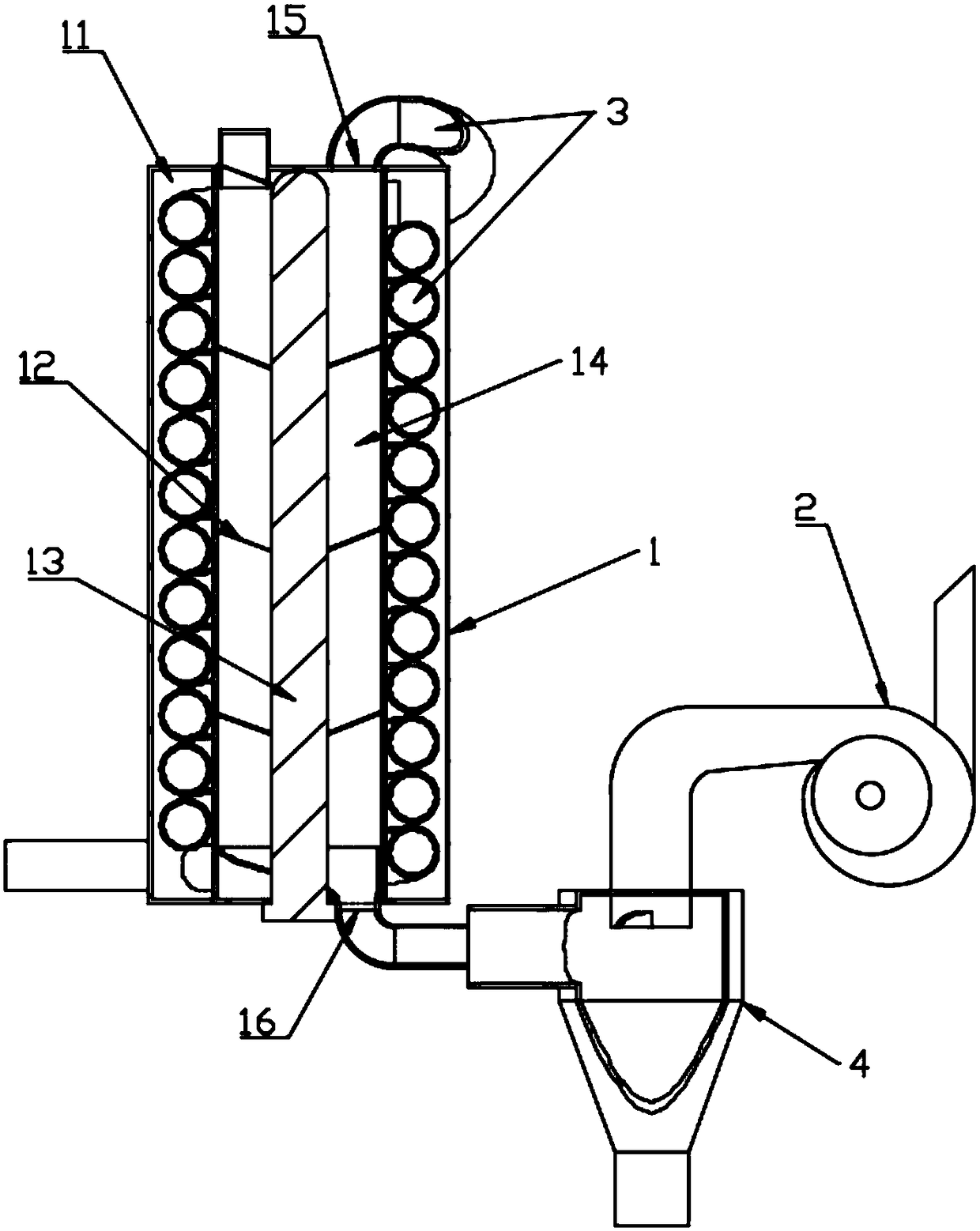

[0032] A negative pressure ignition separation device includes a furnace body 1 and a fan 2, the furnace body 1 includes a furnace wall 11, a baffle plate 12 and an ignition pipe 13; the furnace wall 11 encloses a vertical airtight furnace chamber 14 , the top of the furnace 14 is provided with an air inlet 15, the bottom of the furnace is provided with an air outlet 16 and communicates with the fan 2; the ignition pipe 13 is vertically arranged in the furnace 14, and a plurality of the The baffle plate 12 is airtightly connected with the furnace wall 11 and the ignition pipe 13 and is inclined downward, so that the furnace hearth 14 is divided into four upper and lower layers; and the baffle plate 12 at the bottom of each layer of the furnace hearth 11 is formed with a cutting And ventilated drop opening 17, the aperture of described drop opening 17 decreases gradually from top to bottom.

[0033] The working mechanism of this embodiment is: the blower fan 2 works to make oxy...

Embodiment 2

[0040] This embodiment adopts the device structure and mechanism described in embodiment 1 to implement, the difference is:

[0041] In the furnace 24, there is only one drop opening 27 formed by the baffles 22 of each layer of the furnace 24, so that the air flow channel in the furnace 24 is single. This structural arrangement can prevent the short circuit of the intake air passage and the uneven combustion of fuel.

[0042] Specifically, the furnace 24 is in the shape of an elliptical column; the two ignition tubes 23 are respectively arranged on the left and right sides of the furnace 24, and are airtightly connected with the furnace wall 21; the baffle 22 is long Strip shape, one end is airtightly connected with the left and right two described ignition tubes 23 alternately from top to bottom, and the other end is surrounded by the non-connected described ignition tubes 23 and the furnace walls on both sides to form the drop opening 27; From top to bottom, the length of t...

Embodiment 3

[0044] This embodiment adopts the device structure and mechanism described in embodiment 2 to implement, the difference is:

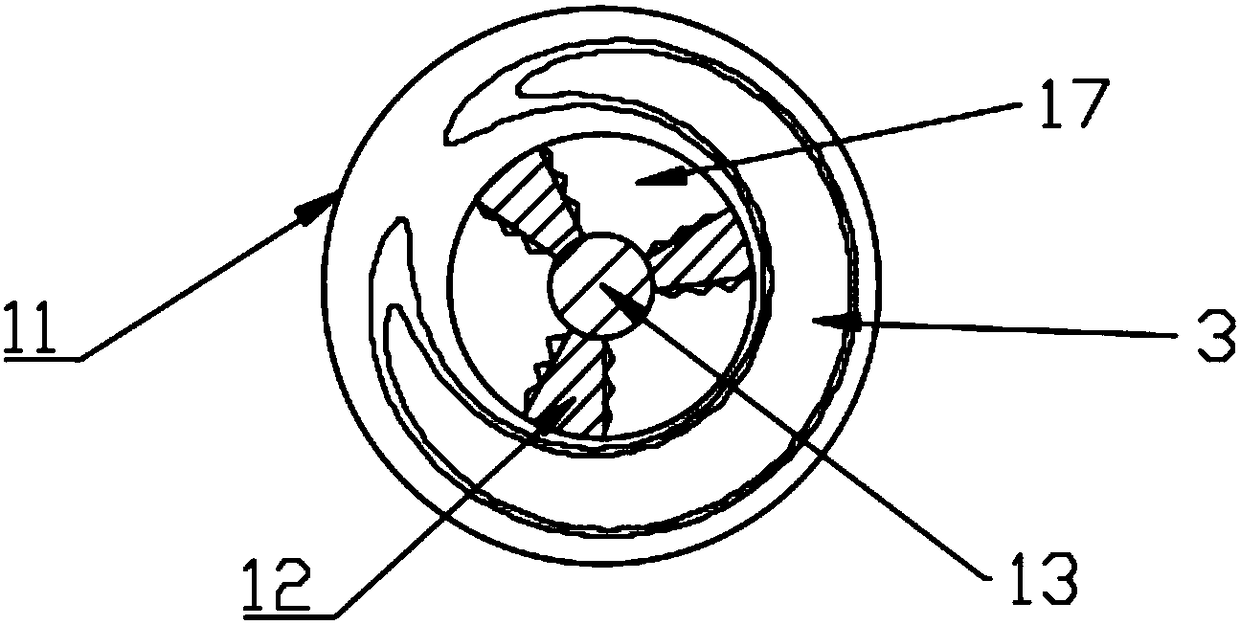

[0045] The furnace 34 is cylindrical, and the ignition tube 33 is arranged in the center of the furnace; the baffle plate is an eccentric funnel 32, and the ignition tube 33 passes through the side wall of the funnel 32, and is connected with the The baffle is airtightly connected, the upper edge of the funnel 32 is airtightly connected with the furnace wall 31, the funnel 32 is biased between the ignition tube 33 and the furnace wall 31, and the bottom opening forms the drop opening 37; from top to bottom, the eccentric positions of the drop openings 37 are arranged alternately left and right. The baffle plate has an arc-shaped bottom surface, which promotes the fuel to roll or slide downward to reach the lower drop opening 37 during the burning and falling process, avoiding the generation of blanking dead ends, and improving the combustion heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com