Combing machine

A combing machine and combing technology, applied in the field of combing machines, can solve the problems of inability to visually monitor the material flow and the accessibility of circular combers, etc., and achieve improved visual observation, improved accessibility, and compensation effect of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

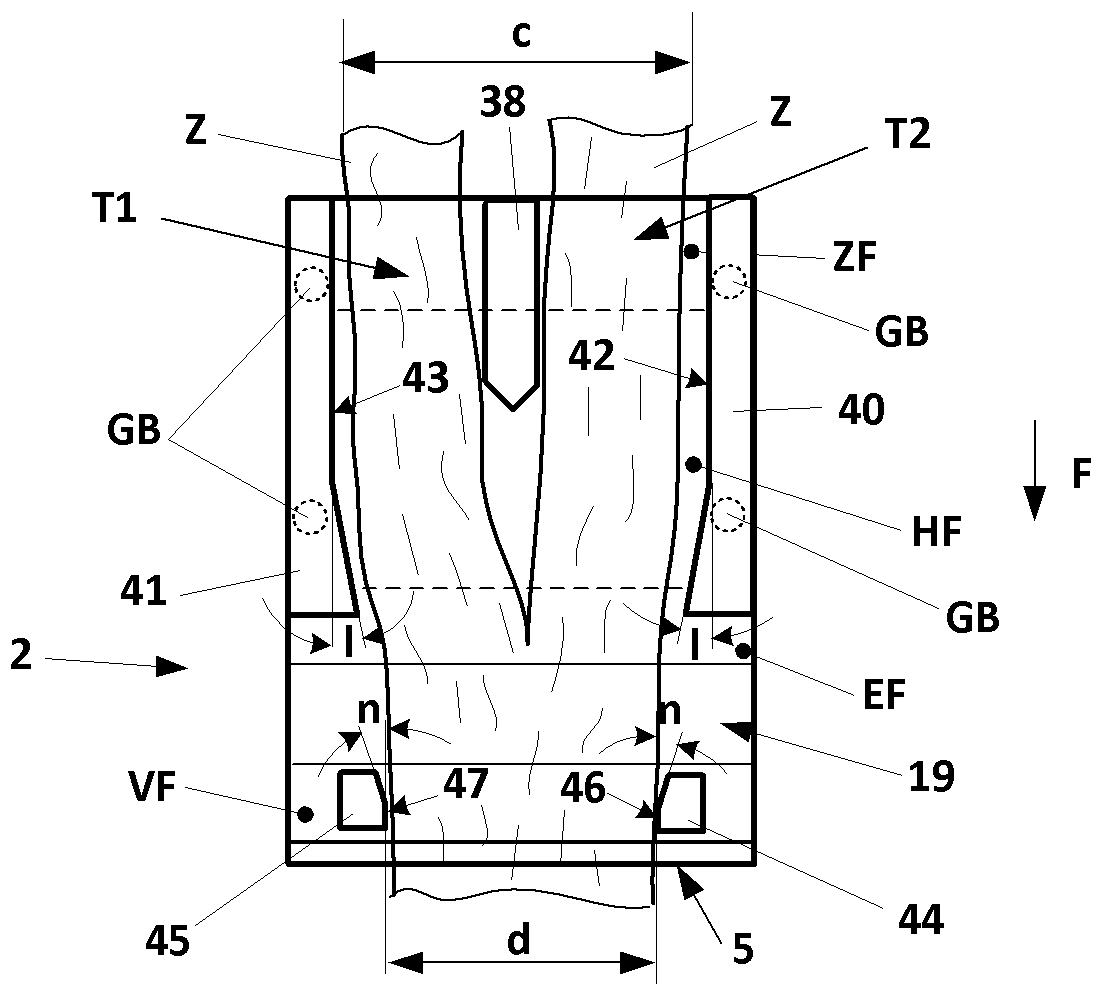

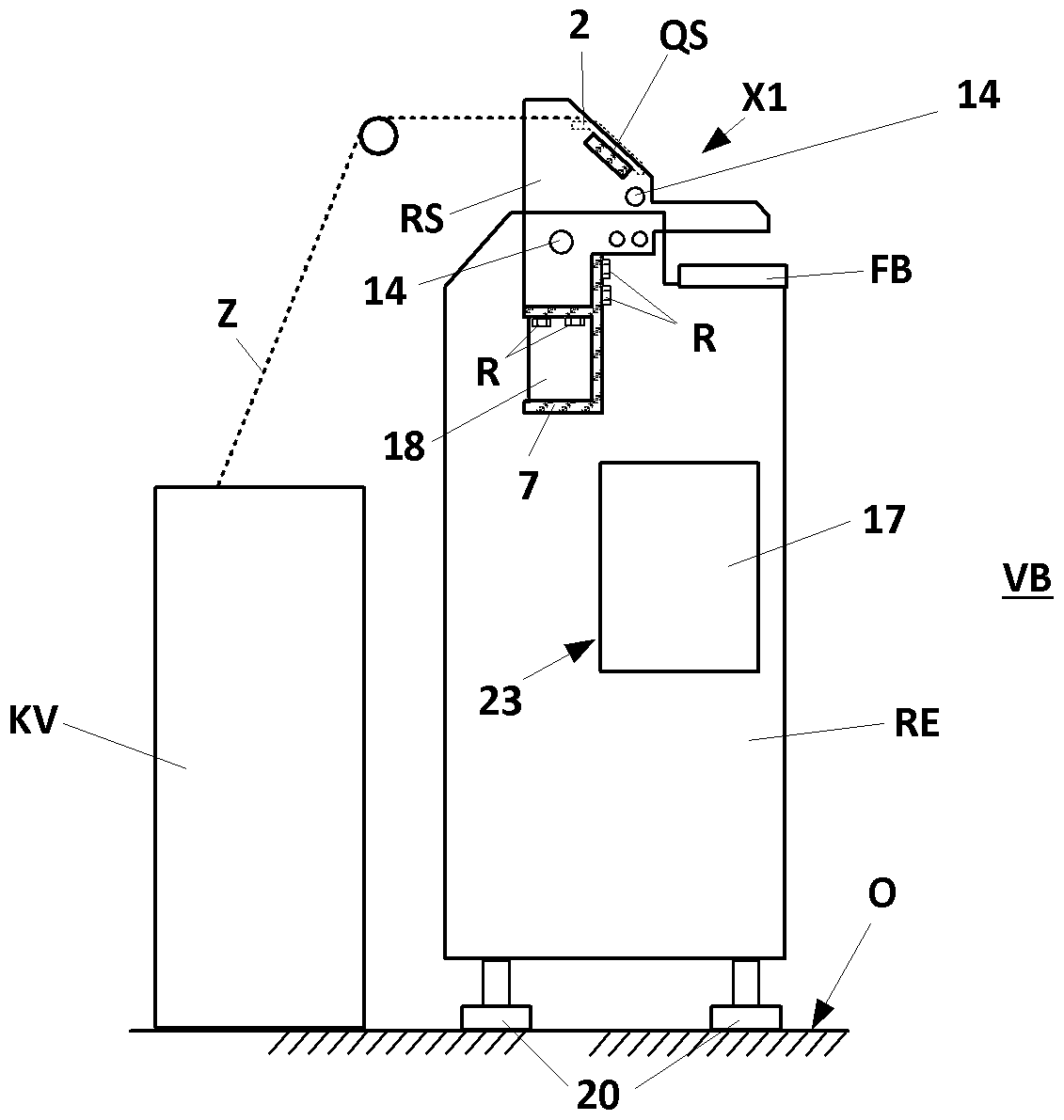

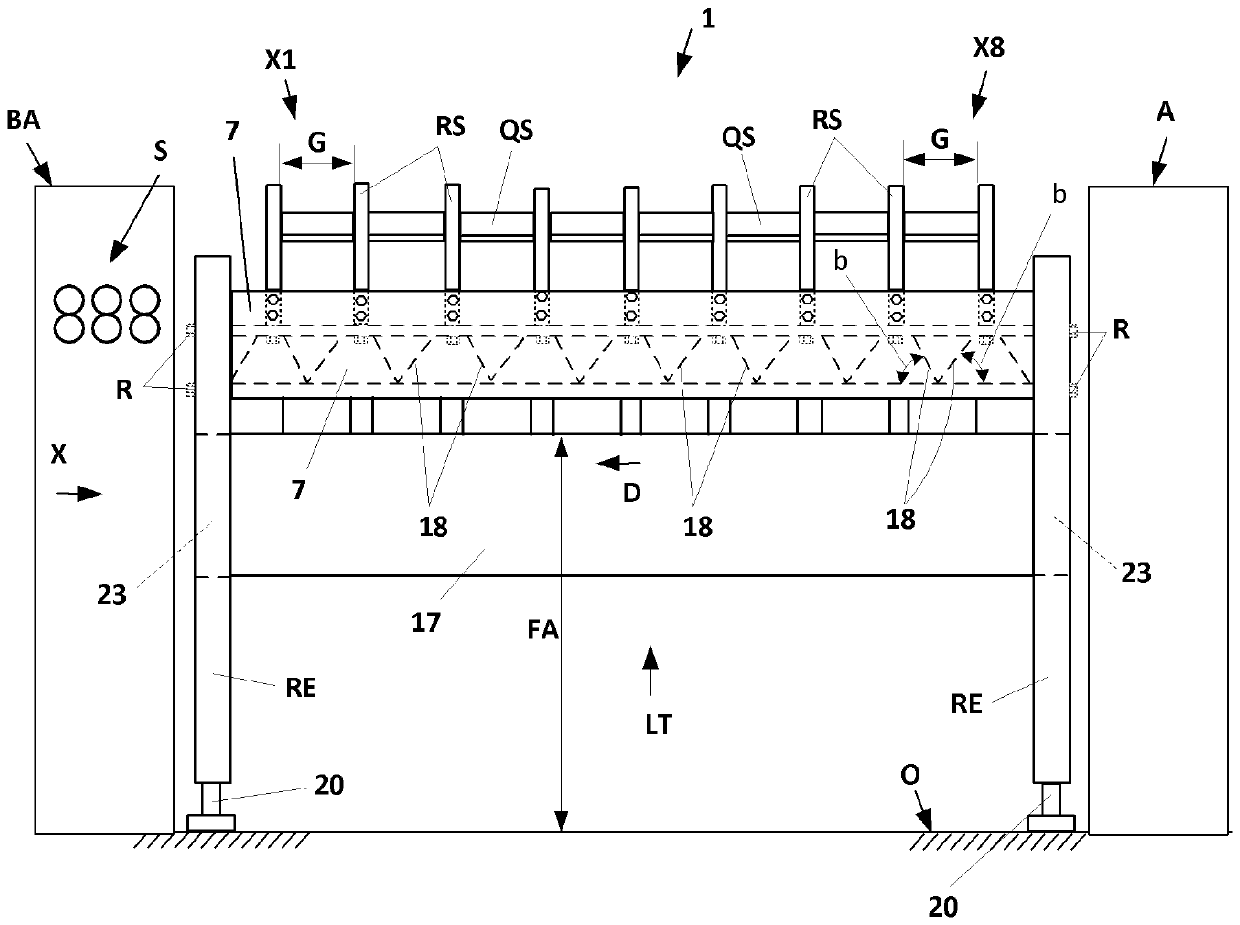

[0028] figure 1 A known embodiment of a combing machine 1 is shown, in which the longitudinal part LT extending between the drive unit A and the sliver laying device BA has a longitudinal beam 8 to which a plurality of combing units X1 to X16 arranged side by side are attached. to the stringer. These combing units generally have smaller dimensions than the combing heads of conventional combing machines, in particular because the combing units are supplied here with only two fiber slivers Z, which are positioned from the longitudinal beam 8 Draw out from the containers F2 to Fx below.

[0029] As shown in FIG. 8 in the publication DE 10 2006 026 841 A1, the combing units X1 to X16 with a width C are arranged directly next to each other and are screwed to the beam 8 . The combing units X1 to X16 each have a housing provided with a corresponding bearing point for supporting the drive shaft driven by the drive unit A.

[0030] The fiber sliver B found on the individual combing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com