High-efficiency silicon wafer degumming device

A silicon wafer degumming and high-efficiency technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of residue, unfavorable cleaning, unsatisfactory degumming effect, etc., to protect safety, improve utilization, and improve degumming effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

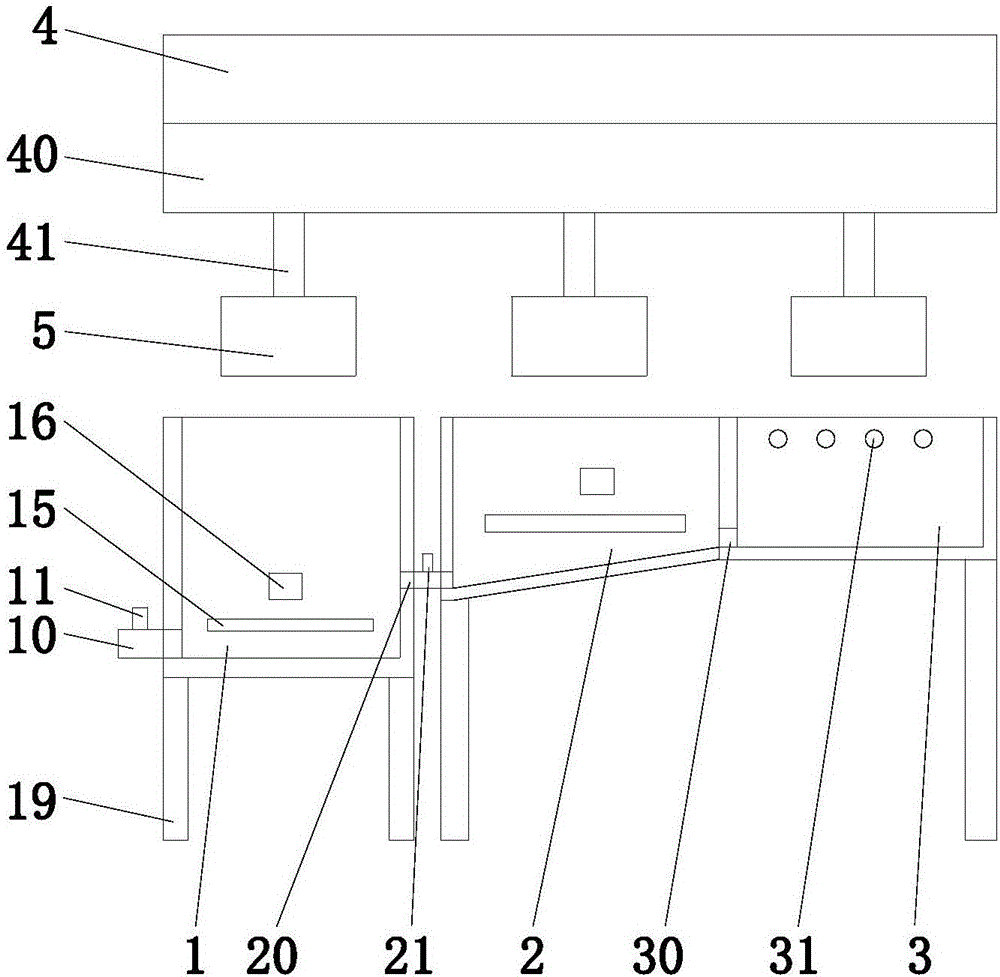

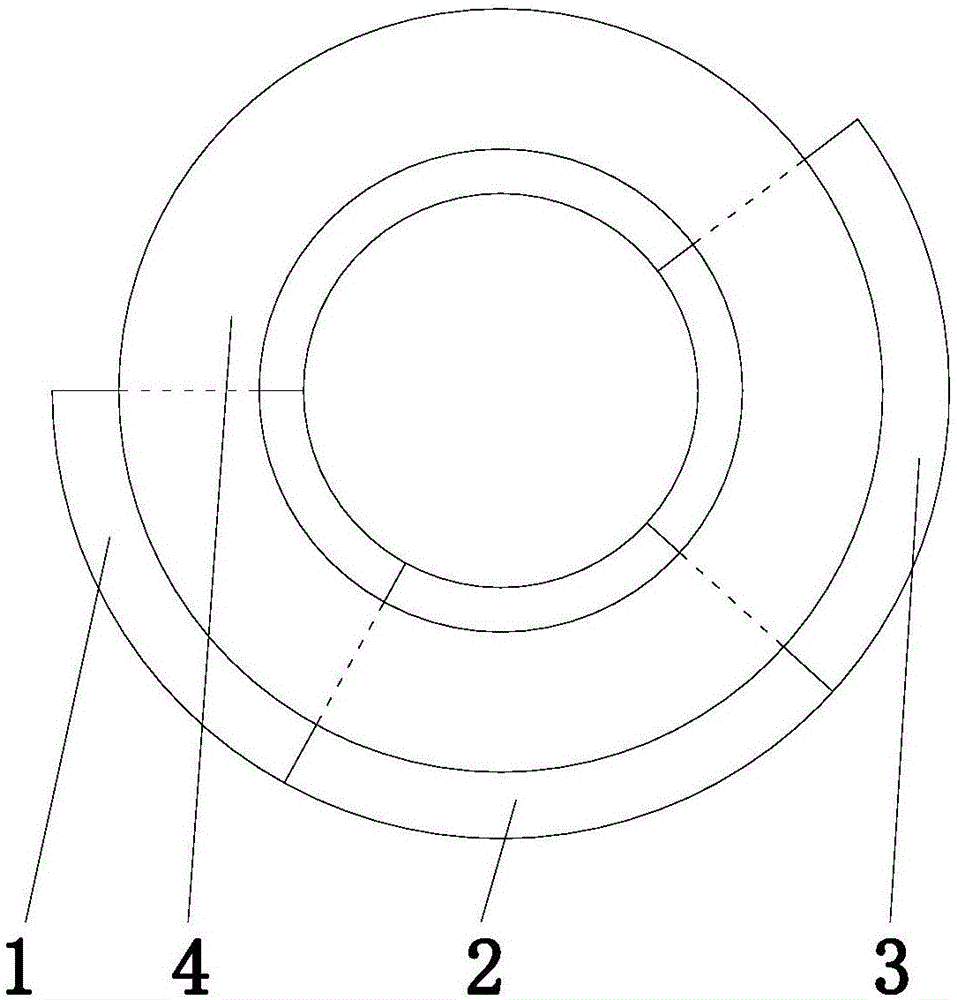

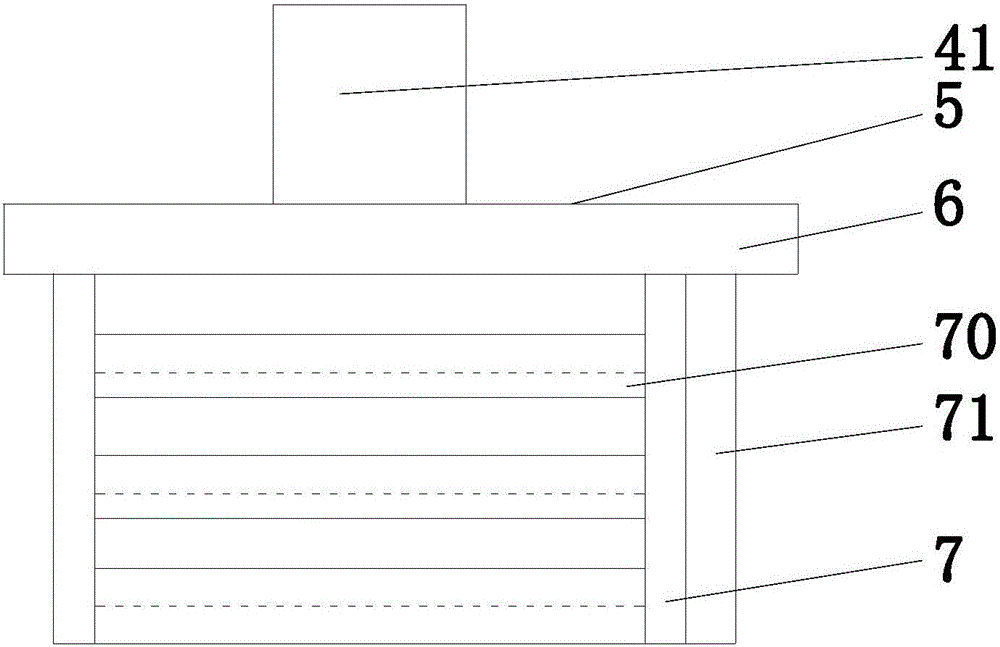

[0023] refer to figure 1 , figure 2 , image 3 and Figure 4 , a high-efficiency silicon wafer degumming device of the present invention comprises a fixed ring frame 4, a movable ring frame 40, a degumming support 5, a first degumming tank 1, a second degumming tank 2, and a filtrate tank 3. The fixed ring frame 4. A rotatable movable ring frame 40 is installed at the bottom, and 5 mutually independent telescopic rods 41 are installed on the bottom of the movable ring frame 40. The bottom of the telescopic rods 41 is fixed with a degumming support 5, and the degumming support 5 consists of a top plate 6, a vertical Composed of upright columns 7, U-shaped frames 70, and baffle plates 71, four vertical columns 7 are fixed on the bottom of the top plate 6, and the four vertical columns 7 form a rectangular array. A number of horizontally arranged U-shaped frames 70 are fixed up and down. The cross-section of the U-shaped frames 70 is L-shaped, and the opening ends of all U-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com