Fireproof shielding window for ship

A technology for shielding windows for ships, which is applied in the field of windows, can solve the problems of high manufacturing cost, much space occupied, and cumbersome installation process, and achieve the effects of occupying less space, facilitating installation and maintenance, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

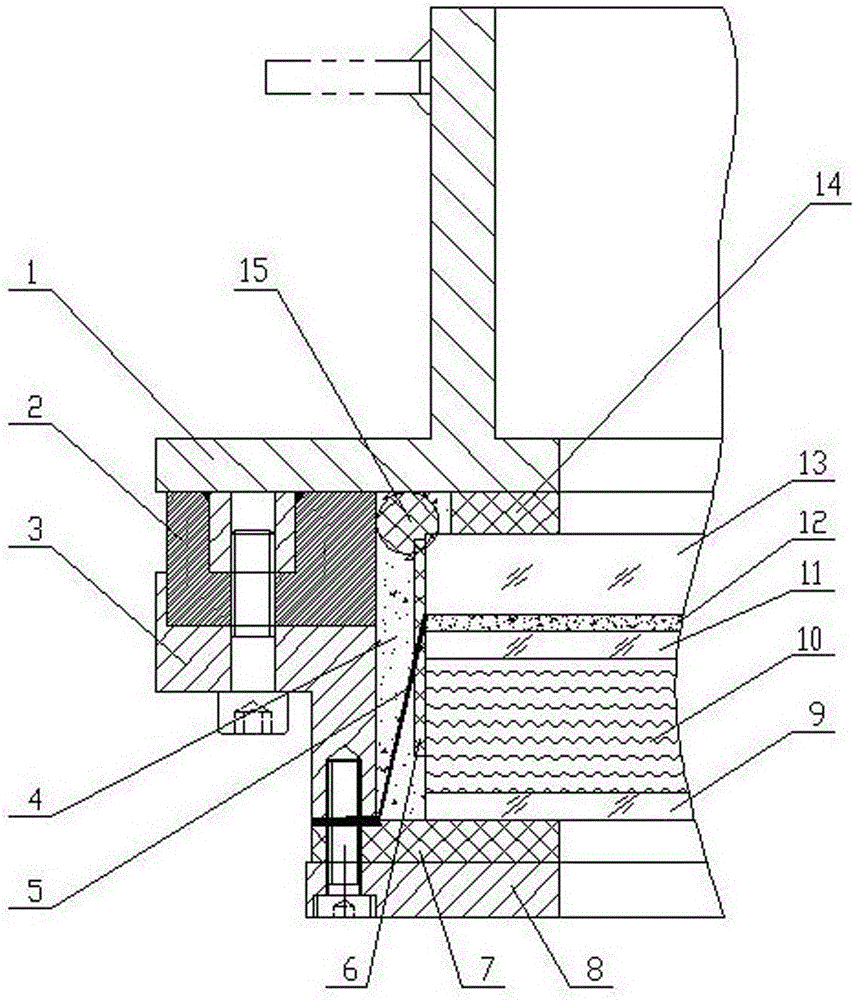

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

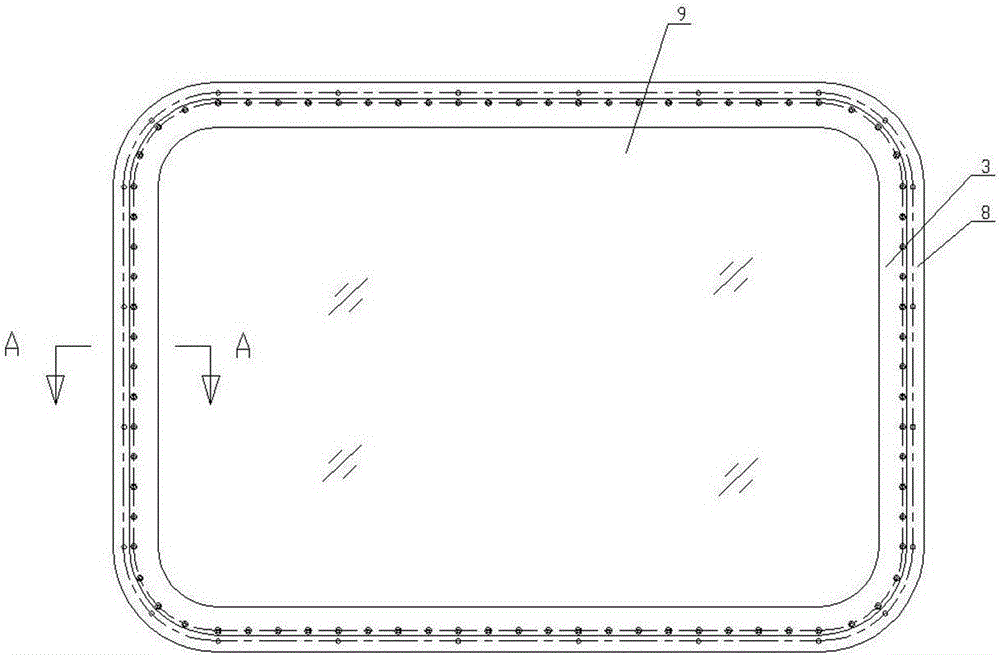

[0018] Such as figure 1 and figure 2 As shown, the ship fire shielding window of the present invention includes a window frame 1 and a window leaf. The window leaf includes a frame 3, which is detachably connected to the window frame 1, and the frame 3 is provided with glass. The glass is fireproof shielding glass. A pressing plate 8 is arranged on the outside of the glass, and the periphery of the pressing plate 8 is connected with the frame 3 . The surroundings of the inner surface of the glass and the outer surface of the window frame 1, and the surroundings of the outer surface of the glass and the inner surface of the pressing plate 8 are in a sealed fit. The fire-resistant shielding glass has an inner glass 13, a middle glass 11 and an outer glass 9 from the inside to the outside. There is a first distance between the inner glass 13 and the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com