A Concrete Box Girder Transverse Prestressed Structure

A technology of concrete box girders and prestressed structures, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of little improvement in web crack resistance, increased risk of concrete cracking, and large local tensile stress of concrete, etc., to achieve Increase the effect of lateral prestressing, good application prospects, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

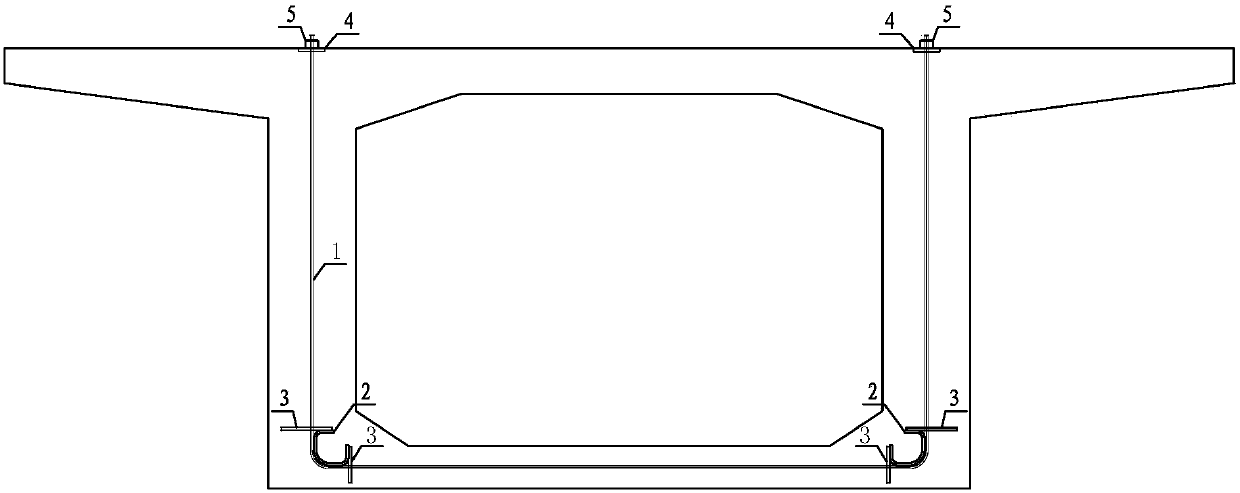

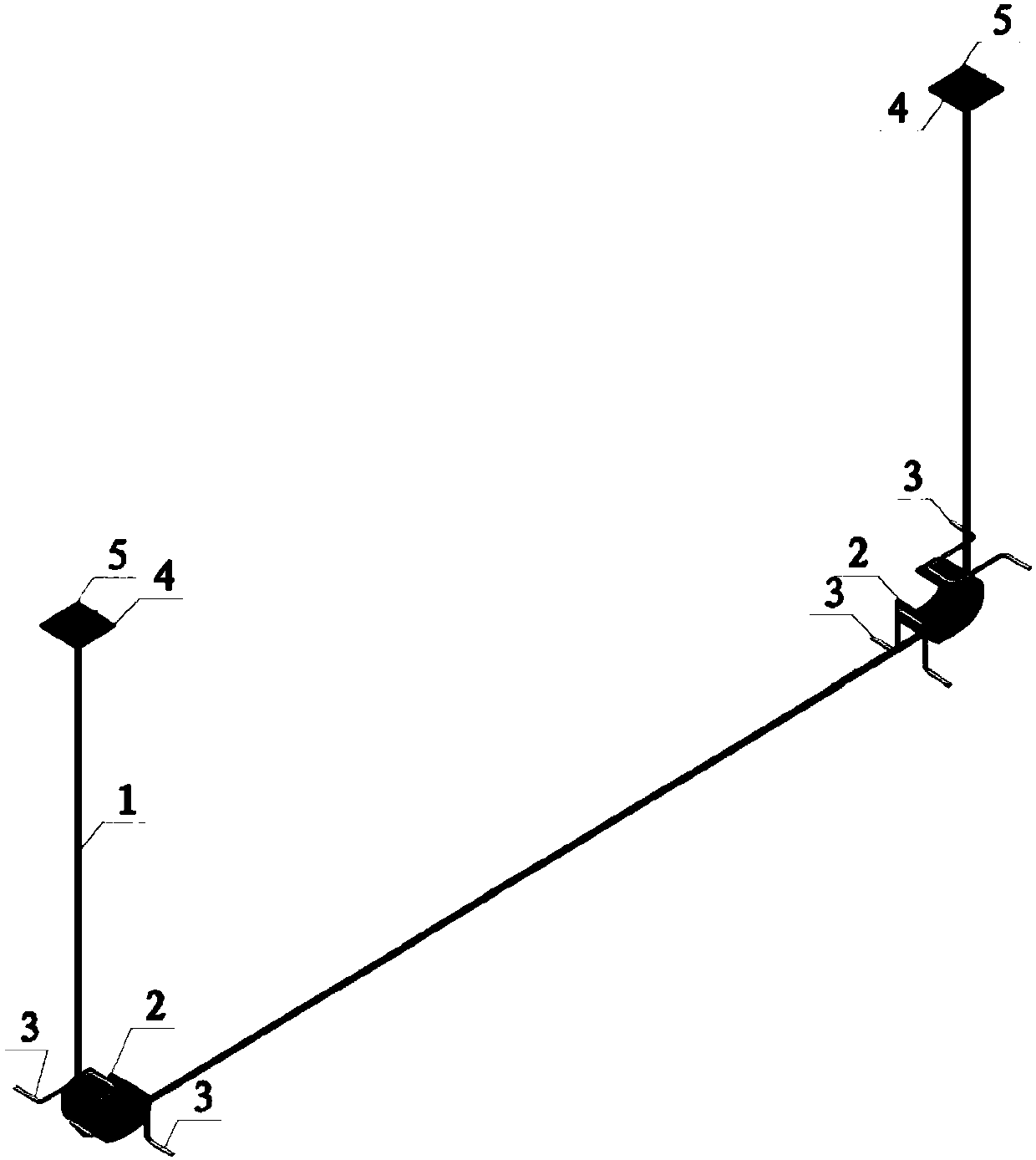

[0010] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0011] A concrete box girder transverse bridge direction prestressed structure, the prestressed material adopts unbonded steel strand prestressed steel tendons 1, the number of unbonded steel strands prestressed steel tendons 1 is determined according to the structural design calculation, and the C-shaped The corner angle of the angle steel 2 is determined according to the angle between the web and the bottom plate, and the width is determined according to the number of unbonded steel strand prestressed steel bundles 1, and the prefabricated C-shaped corner steel 2 is set at the junction of the web and the bottom plate It is used to cling to and support the prestressed steel beam 1 of the unbonded steel strand; one side of the U-shaped anti-collapse steel bar 3 is welded with the C-shaped corner steel 2, and the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com