External pulley set type reversing balancing counterweight system

A technology of a balancing system and a pulley block, applied in the field of lifting, can solve the problems of inconvenient operation, complicated operation, high labor intensity, etc., and achieve the effect of increasing the convenience of work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

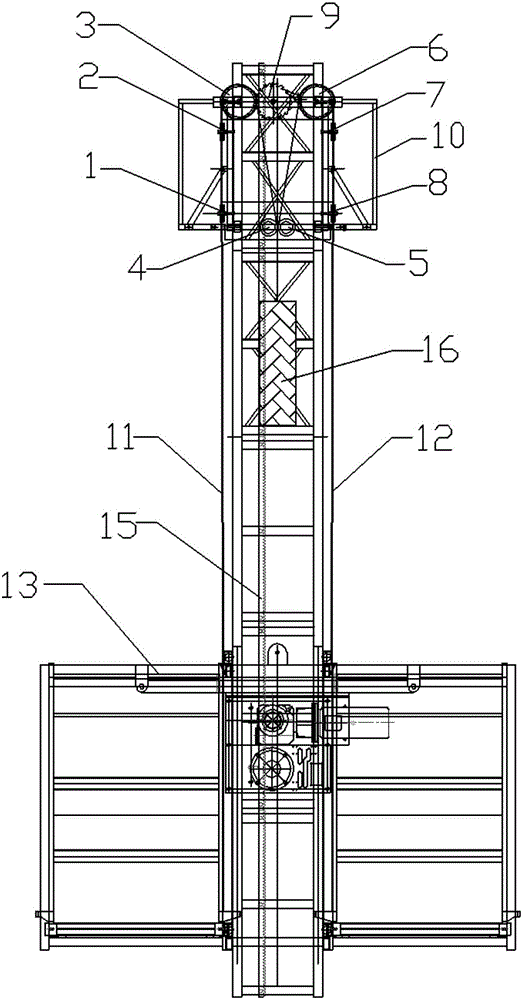

[0022] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

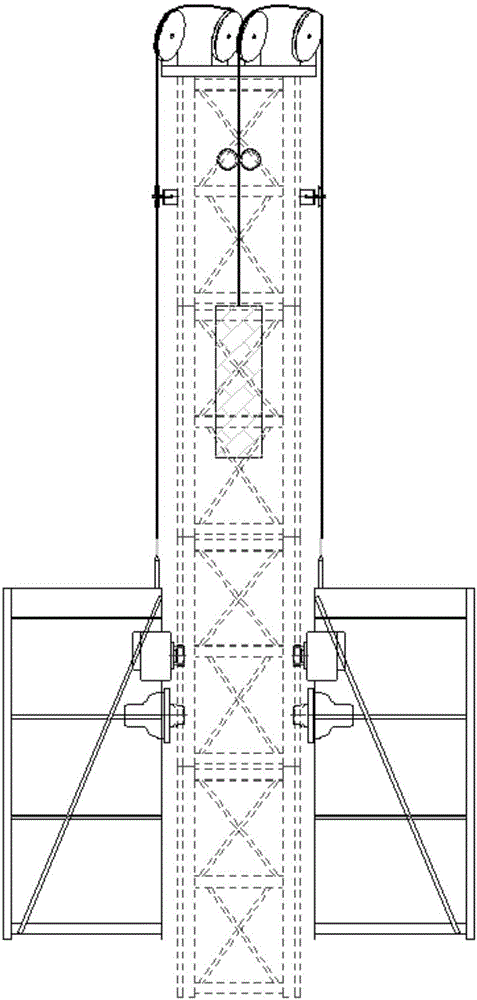

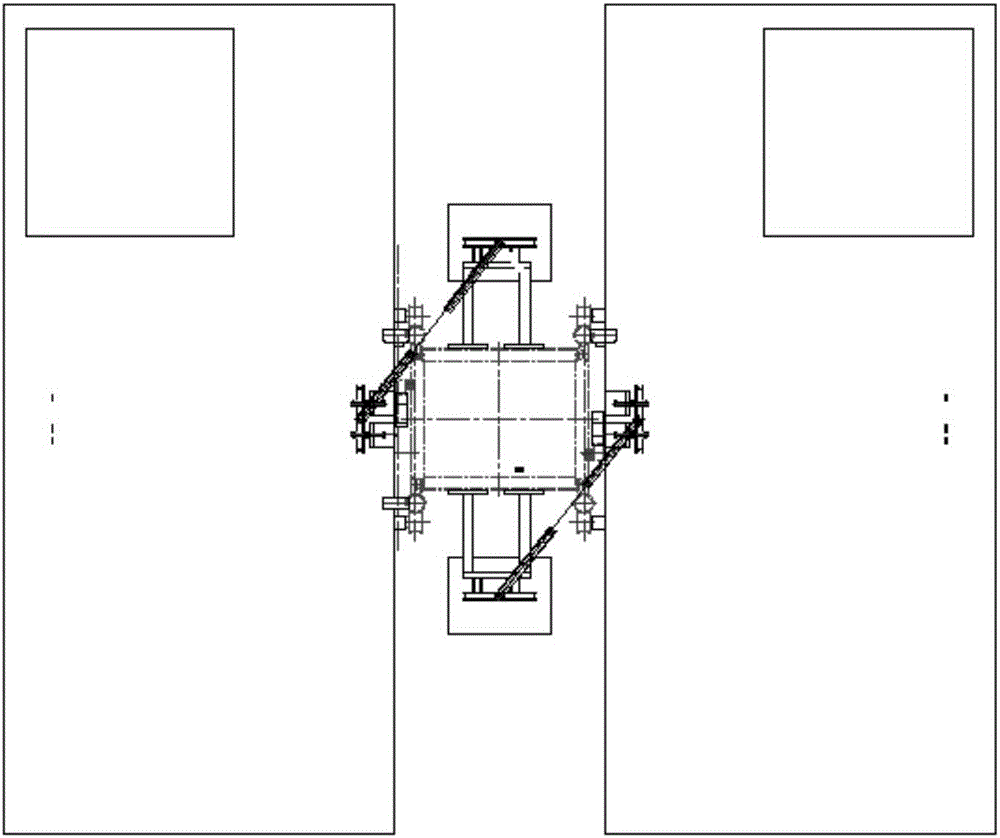

[0023] image 3 It is a schematic diagram of the structure of a jacket type pulley block direction changing balance system of the present invention. Such as image 3 , Figure 4 As shown, a jacketed pulley block direction changing balance system includes a cage 13, a counterweight 16, a jacket pulley guide frame 10, and a unidirectional ratchet 9 forming a unidirectional ratchet assembly. The outer pulley guide frame 10 has a rectangular truss structure, which is installed and sleeved outside the standard section 14 and can move up and down along the standard section 14 track. The unidirectional ratchet assembly mounted on the back of the outer pulley guide frame 10 meshes with the vertical rack 15 of the standard section 14 to form a unidirectional ratchet system. Two symmetrical guide pulleys I and VIII are installed on the bottom of the front o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com